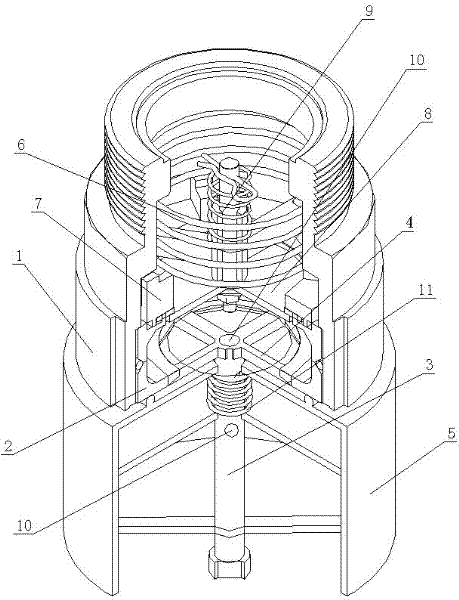

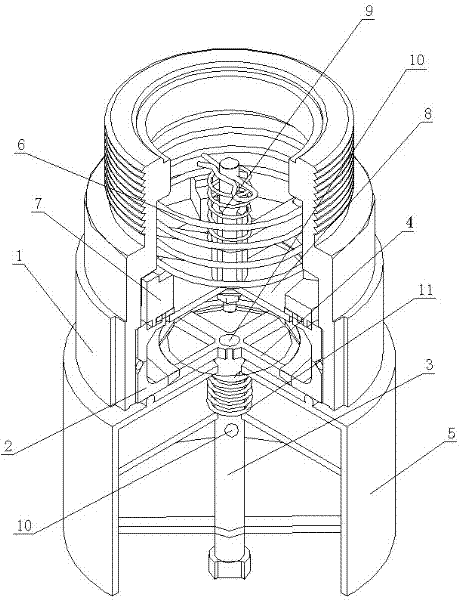

Two-stage pressure-control overflow-preventing breather valve

A pressure control and breathing valve technology, applied in the field of breathing valves, can solve the problems of inability to realize the anti-overflow function, oil leakage of oil tankers, hidden dangers, etc., so as to improve the breathing safety level, avoid safety accidents, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0016] Referring to the accompanying drawings, the two-stage pressure control anti-overflow breathing valve in the figure includes a breathing valve body 1 and an exhaust valve seat 2 provided at the bottom, and the upper part of the breathing valve body 1 has an intake valve stem and a The breathing valve plate 8 installed at the bottom of the intake valve stem, and the intake valve spring 9 set on the intake valve stem, when the pressure inside and outside the valve body is balanced, the upper end of the breathing valve plate 8 is matched with the lower end of the exhaust valve core It constitutes a seal; it is characterized in that: the exhaust valve core 7 is pressed on the exhaust valve seat by the exhaust valve spring 6; Through the central hole of the top and bottom plates, it is dynamically matched with the buoy rod. The buoy rod 3 in the buoy is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com