Hydraulic control loop of high/low-temperature test bed for automatic transmission valve

A high and low temperature test, automatic transmission technology, applied in the testing of machine/structural components, instruments, and mechanical components, etc., can solve the problem that the oil temperature of the valve body has a great influence, only the engine speed is not taken into account, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, structure and specific working method of the present invention are described in detail:

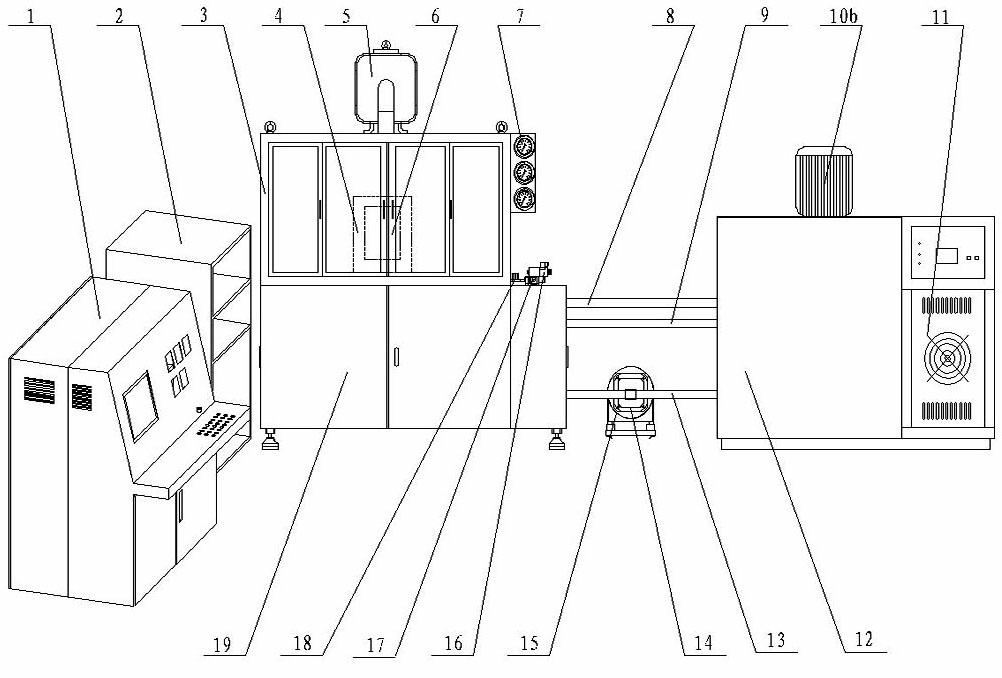

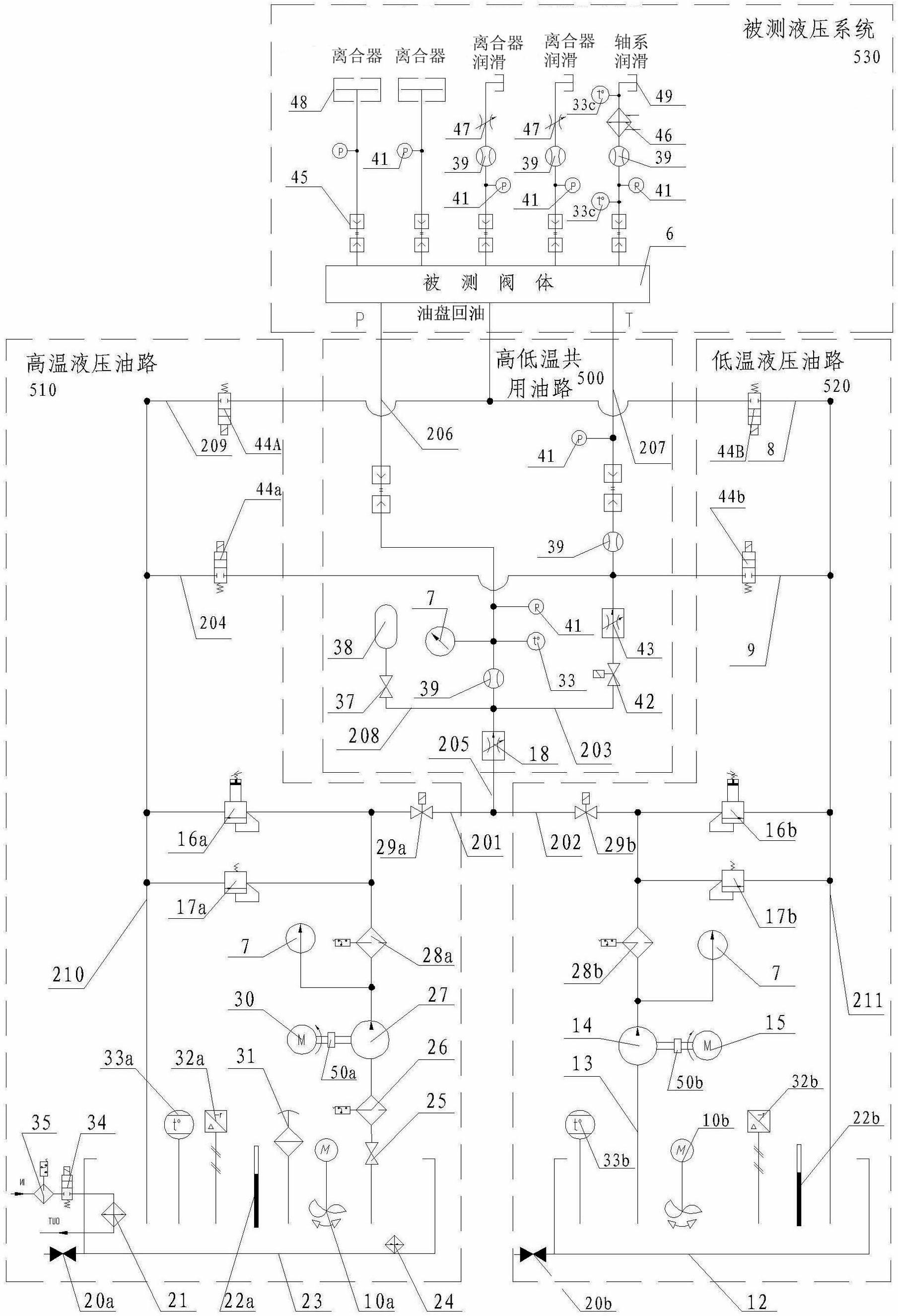

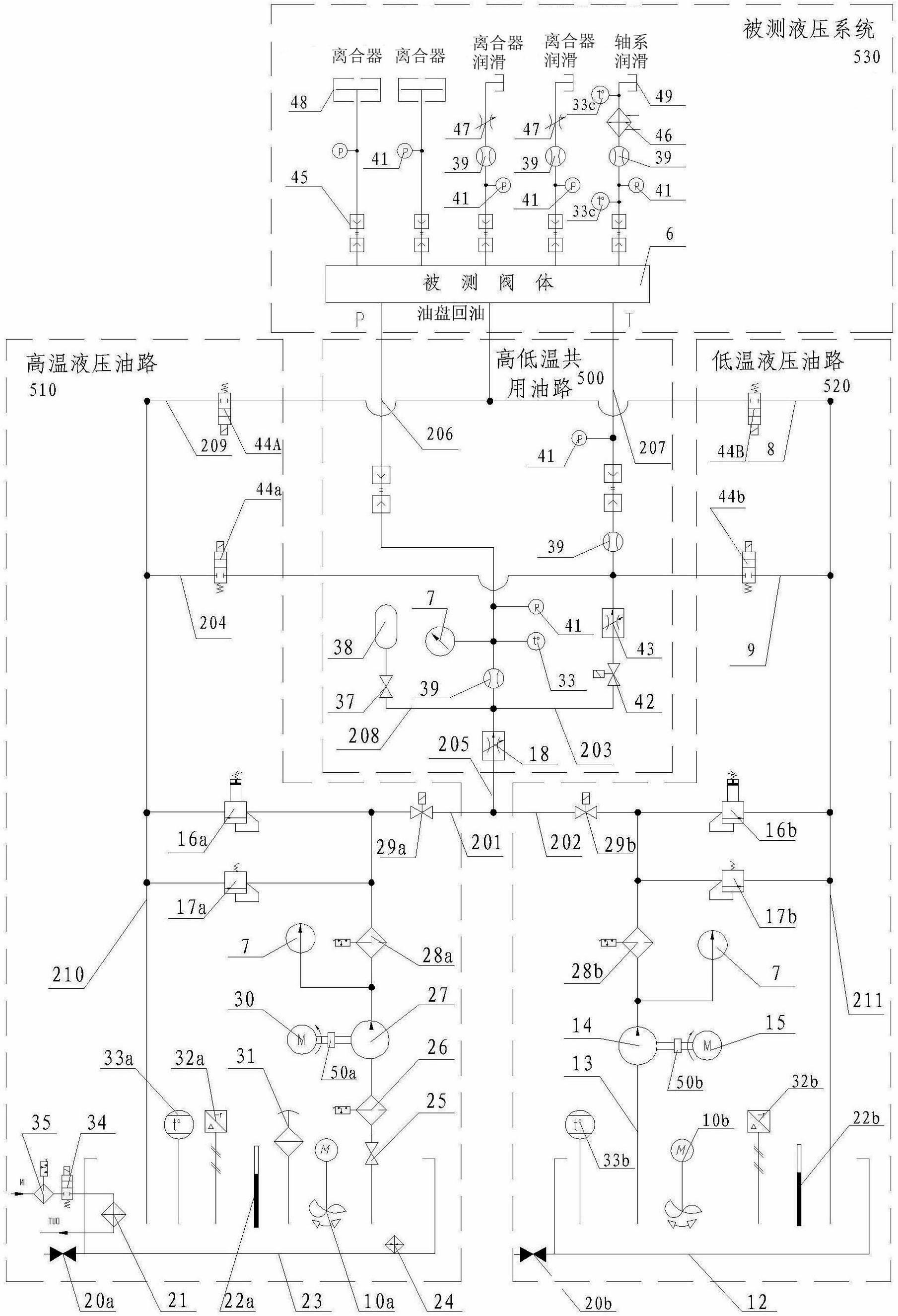

[0025] see figure 1 The automatic transmission valve body high and low temperature hydraulic test bench is mainly composed of control cabinet 1, power box 2, test chamber 3, test valve body connecting plate 4, oil mist collector 5, test valve body 6, pressure gauge 7, low temperature tray oil return pipe 8 , low temperature oil return pipe 9, low temperature system oil tank oil agitator 10, refrigeration unit 11, low temperature system oil tank 12, low temperature oil suction pipe 13, low temperature system oil pump 14, low temperature system servo motor 15, proportional overflow valve 16, system safety valve 17. The main speed regulating valve 18 of the oil inlet circuit, the high-temperature hydraulic pump station 19, and the workbench 100 are composed. Among them, the control cabinet 1 mainly implements the pressure of each ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap