Four-degree-of-freedom decoupling hybrid robot

A technology with a degree of freedom and a robot, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as small working space, complex structure, and poor dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

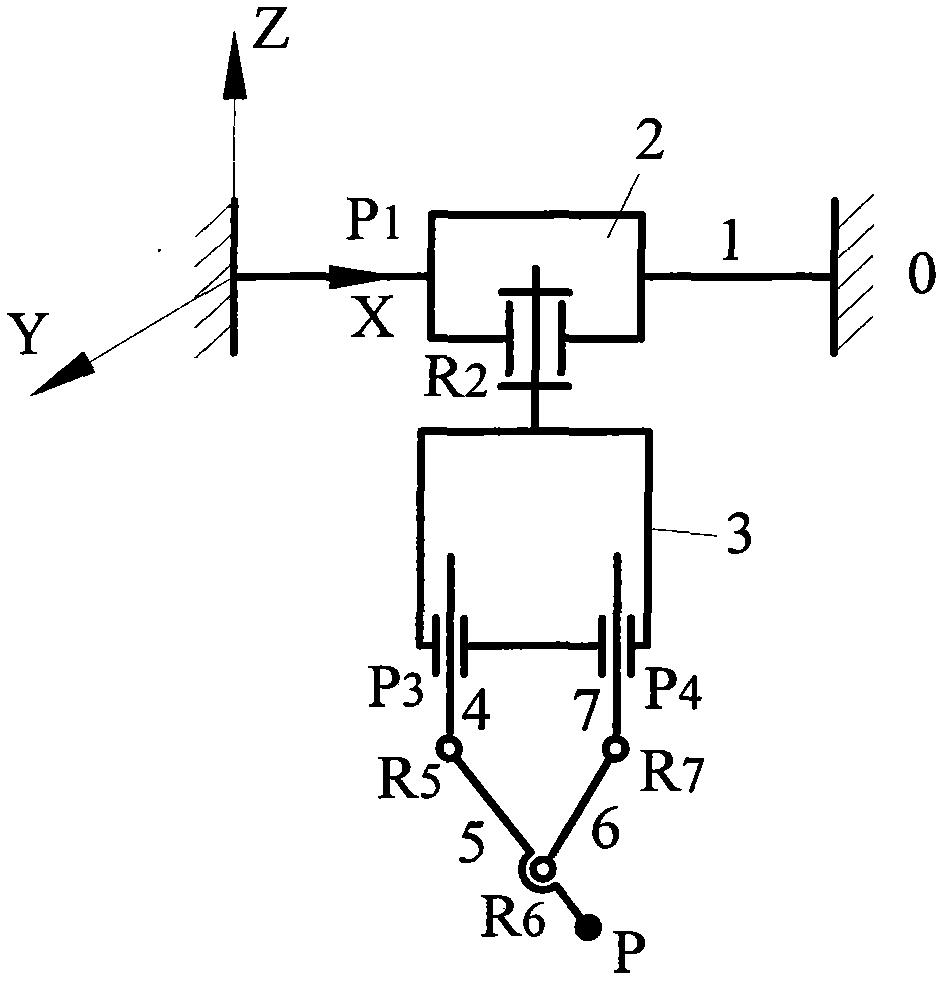

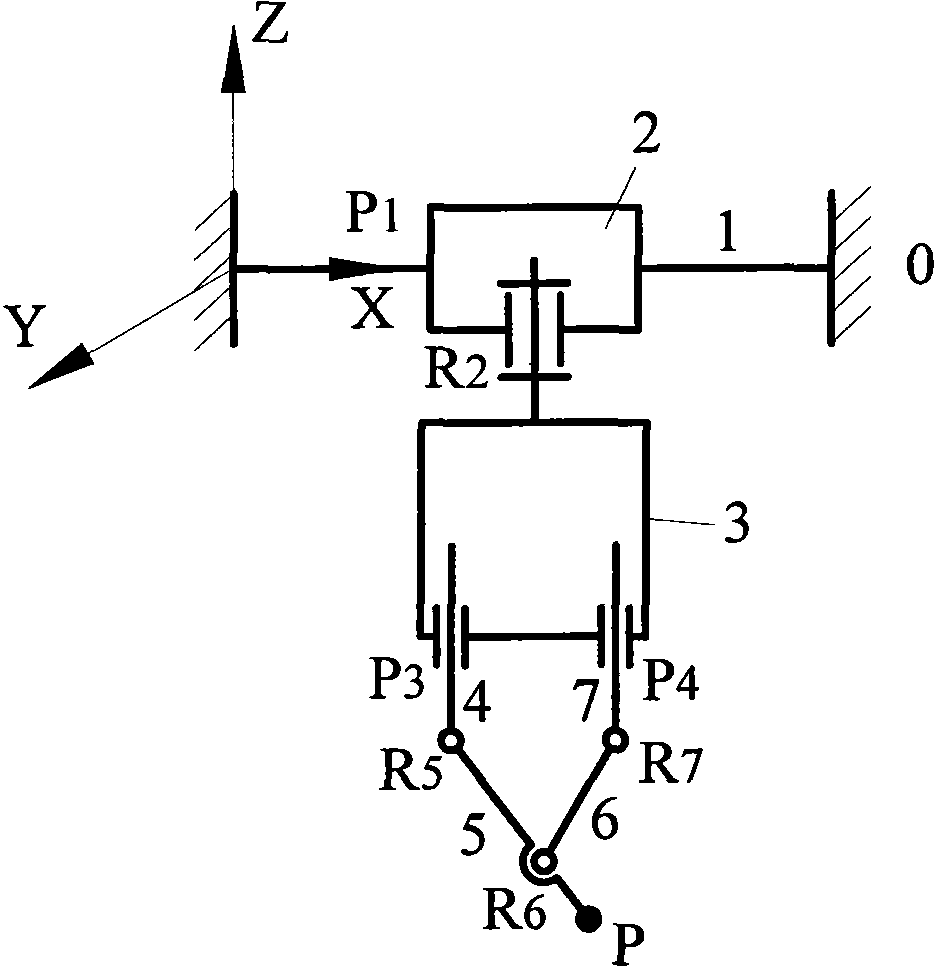

[0008] attached figure 1 It is a schematic diagram of the first structure of the embodiment of the present invention. A four-degree-of-freedom decoupling hybrid robot, including a frame 0, a guide rail 1, a slider 2, a large rotating arm 3, and a two-degree-of-freedom planar parallel mechanism operator P 3 -R 5 -R 6 -R 7 -P 4 , slider 2 to move vice one P 1 After being connected with the guide rail 1 fixed on the frame 0, the rotating pair R 2 Connect the large rotating arm 3; install a two-degree-of-freedom planar parallel mechanism operator on the large rotating arm 3, that is, the component one 4, component two 5, component three 6, and component four 7 of the planar parallel mechanism operator are respectively rotated Deputy second R 5 , rotating pair three R 6 , rotating pair four R 7 After the connection, component 1 4 and component 4 7 move the secondary P 3 , mobile deputy three P 4 Connected with the large rotating arm 3, the movement plane of the operator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com