Injection mould and manufacturing method thereof

An injection mold and manufacturing method technology, applied in the field of injection mold manufacturing, can solve the problems of defective finished products, time-consuming, manpower and material resources, time-consuming and labor-consuming, etc., so as to improve damage resistance, reduce production costs, and save Effects of materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

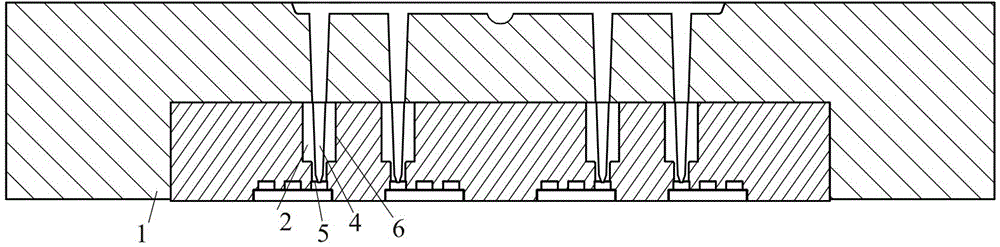

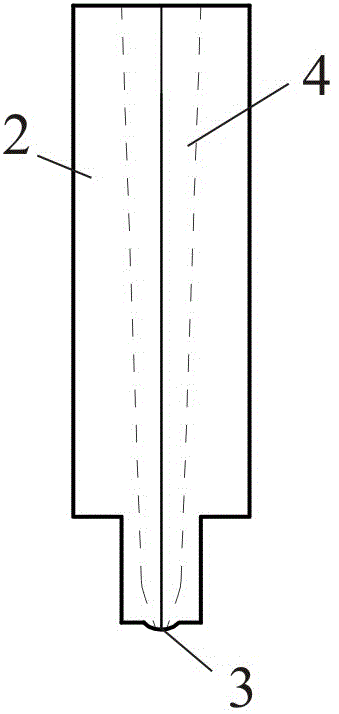

[0018] refer to figure 1 with figure 2 , the purpose of the present invention is an injection mold that can achieve convenient replacement of pouring core parts, increase the service life of the mold and save costs. The invention mainly improves the pouring position at the 5 feeding port of the mold cavity of the injection mold. A detachable pouring core 2 is provided on the mold body. In traditional injection molds, this part is integrated with the mold body, but the innovation of the present invention is to design this part as an independent part independent of the mold body 1, that is, the casting core part 2, the casting core part 2 Of course, there are pouring ports 3 and pouring channels 4. The mold body 1 is provided with a pouring core hole 6 capable of assembling the pouring core 2. The pouring core 2 and the pouring core hole 6 on the mold 1 are connected by a tight fit. Together, that is, the pouring core 2 is fastened on the mold body 1, and the pouring port 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com