Device for detecting quality of machine needle

A detection device and quality technology, applied in the direction of measuring device, photogrammetry/video metrology, surveying and mapping and navigation, etc., can solve the problems of waste of human and material resources, low recognition rate, unstable operation and other problems of enterprises, and achieve collection speed Fast, saving human resources, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

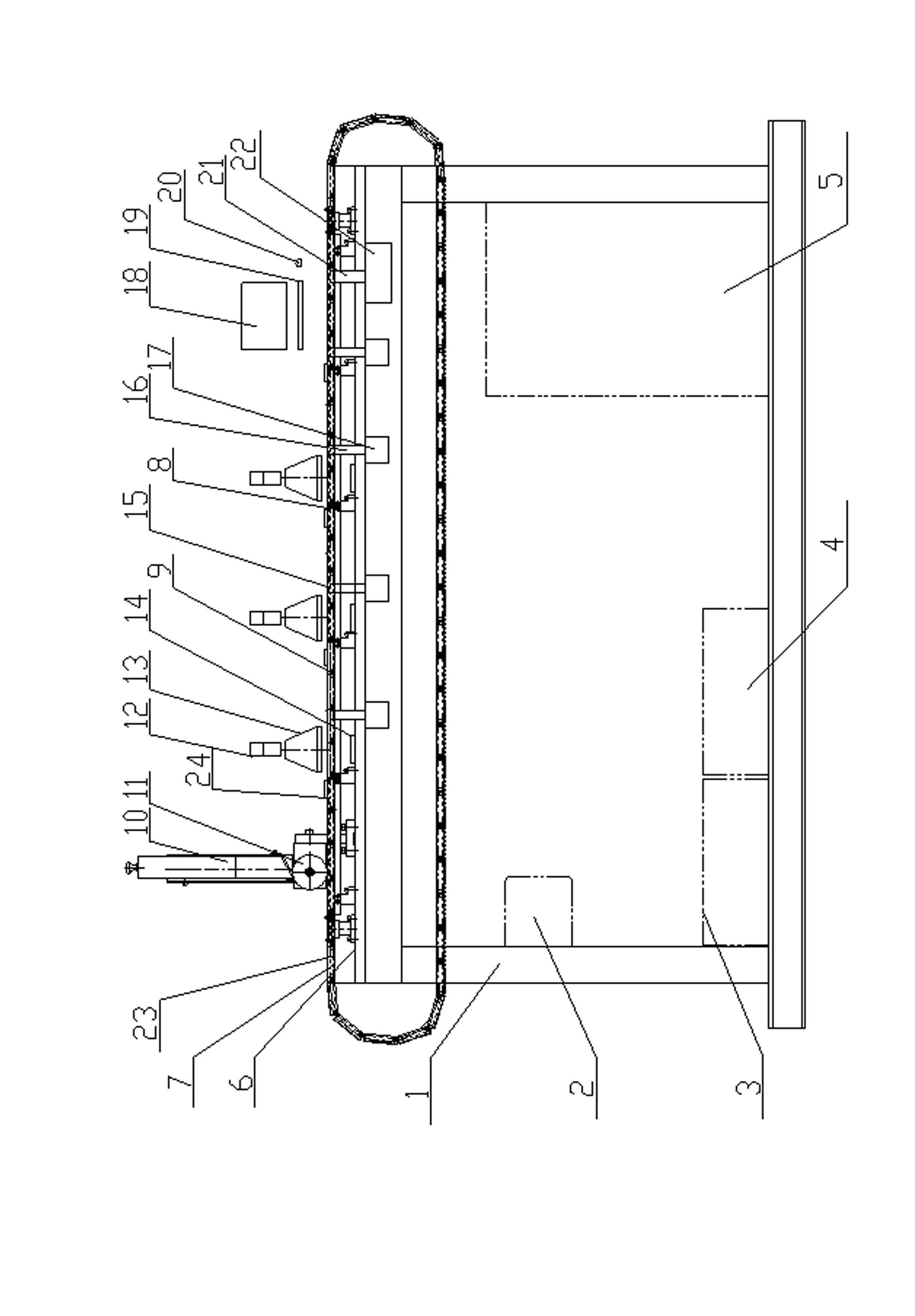

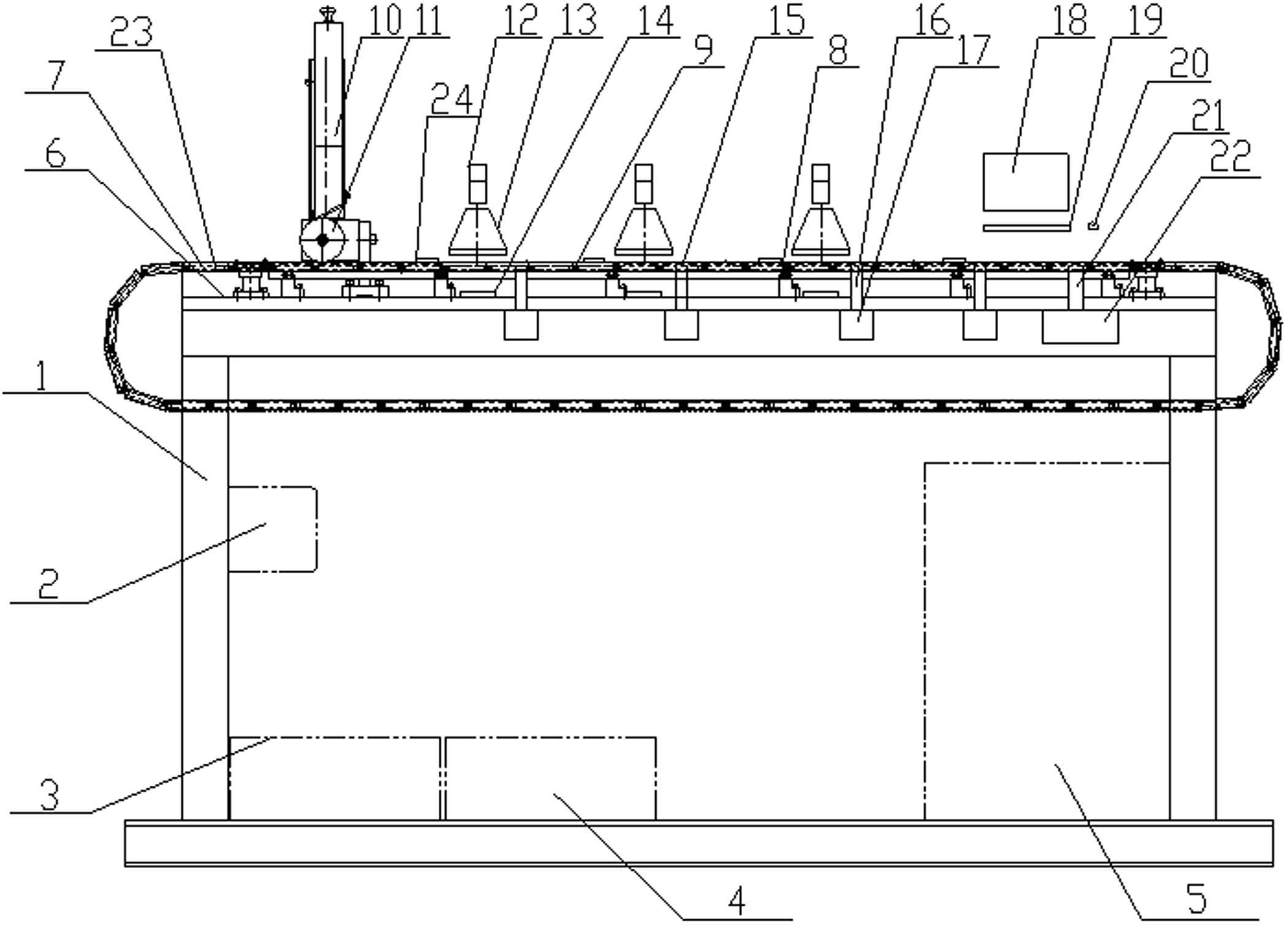

[0014] Such as figure 1 As shown, the machine needle quality detection device of the present invention comprises a square steel support 1, a power system 2, an industrial computer a3, an industrial computer b4 and an electrical box 5 are installed on the outside of the square steel support 1, and the top of the square steel support 1 A work surface 6 is provided, and a plurality of supports 8 are arranged on the work surface 6, and a conveying track 7 is fixed on the support 8, and a hollow conveyor belt 9 is arranged on the conveying track 7, and the bottom of the conveyor belt is laid There are steel belts 23,

[0015] The worktable 6 is also provided with a feeding part, a detection part, a monitoring part and a blanking part in sequence, and the feeding part includes a loading hopper 10, and the charging hopper 10 is connected with a blanking tray 11 and is fixed on the working table 6 , the detection part includes three identical detection components a and detection comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com