Flexible suspension and force sensing device for loader

A flexible suspension and loader technology, applied in measuring devices, instruments, measuring instrument components, etc., can solve problems such as inconvenience in use, and achieve the effects of avoiding inertial force, convenient use and maintenance, and high force decomposition accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

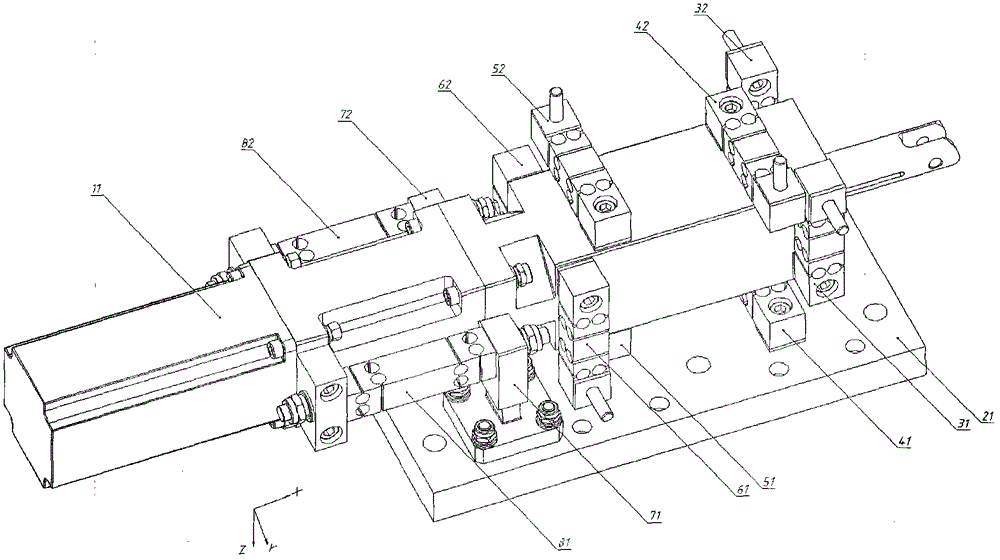

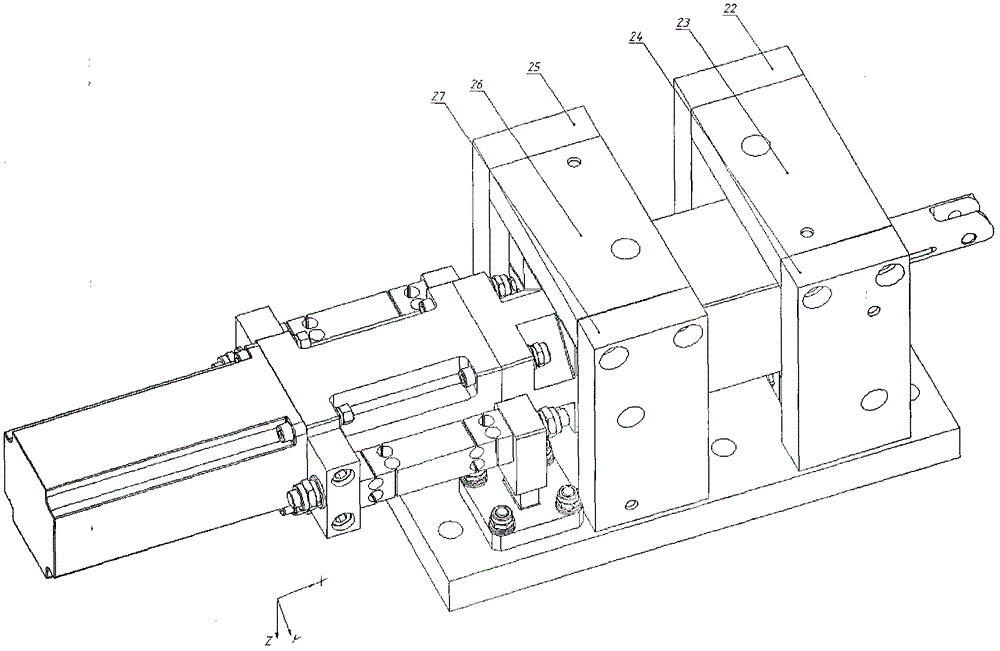

[0023] The present invention is as figure 1 , figure 2 As shown, the force loader 11 is suspended on the support 21 and the brackets 22, 23, 24, 25, 26, 27 by the flexible links 31, 32, 41, 42, 51, 52, 61, 62. The force loaded by the steering gear is equal to the force received by the loader and is applied to the force sensitive element 71 and the force sensitive element 72 through the force measuring flexible link 81 and the flexible link 82. A strain gauge is attached to the force sensitive element 72 to measure the strain of the force sensitive element, and the force on each force sensitive element can be measured. The magnitude of the loaded force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com