Device for testing thermal performance and fluid resistance of liquid-liquid heat exchanger

A fluid resistance and heat exchanger technology, which is applied in measuring devices, measuring fluid pressure, calorimeters, etc., can solve the problems of inability to control temperature, increase secondary heat transfer, waste energy, etc., to reduce high-power operation, The effect of reducing preparation time and stable and accurate flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

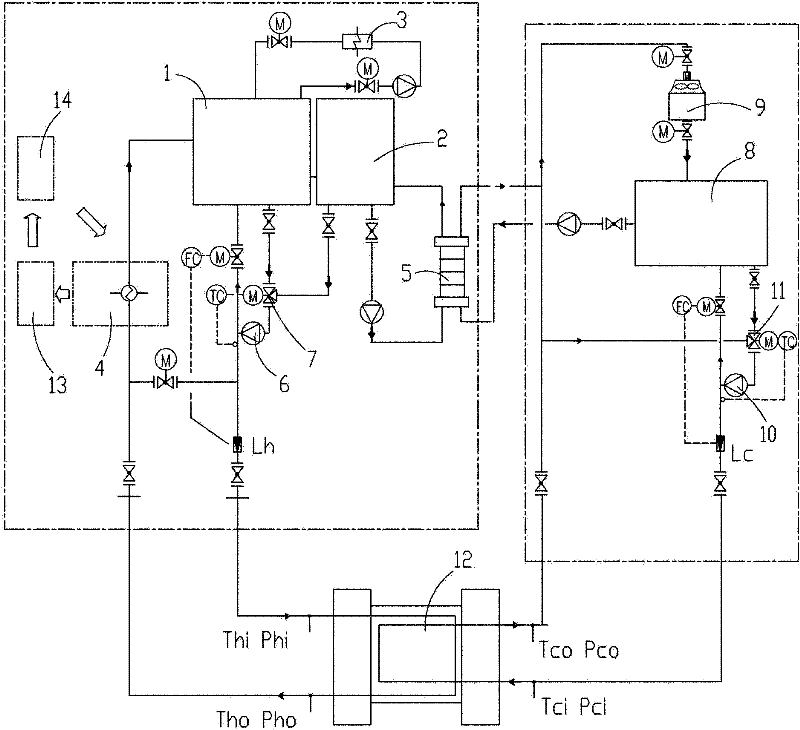

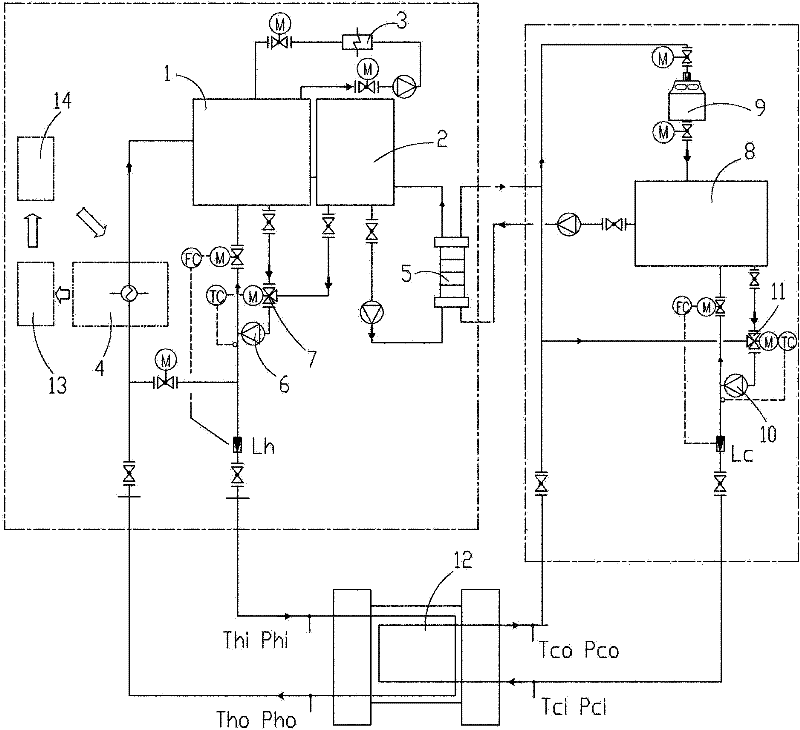

[0024] see figure 2 , in this embodiment, the heat source medium container is composed of a high-temperature container 1 and a low-temperature container 2 arranged separately, and the high-temperature container 1 and the low-temperature container 2 are directly connected by pipelines; the heat source medium outlets of the high-temperature container 1 and the low-temperature container 2 The pipelines are respectively connected to the heat source three-way regulating valve 7, and the heat source frequency conversion pump 6 is installed in the heat source medium outlet pipeline of the heat source three-way regulating valve 7, and the heat source medium of the heat exchanger 12 under test is connected to the outlet pipeline of the heat source frequency conversion pump 6 Inlet: a steam heat exchange unit 4 is set in the heat source medium outlet pipeline of the heat exchanger 12 under test, and the heat source medium that has completed heat exchange in the heat exchanger 12 under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com