Electric speed governor device for electronic fork lift truck

An electric stacker, electronic governor technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of increasing the maintenance cost of electric stacker, contact wear, affecting the life and reliability of the electronic governor, etc. , to achieve the effect of prolonging life, improving reliability and eliminating contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

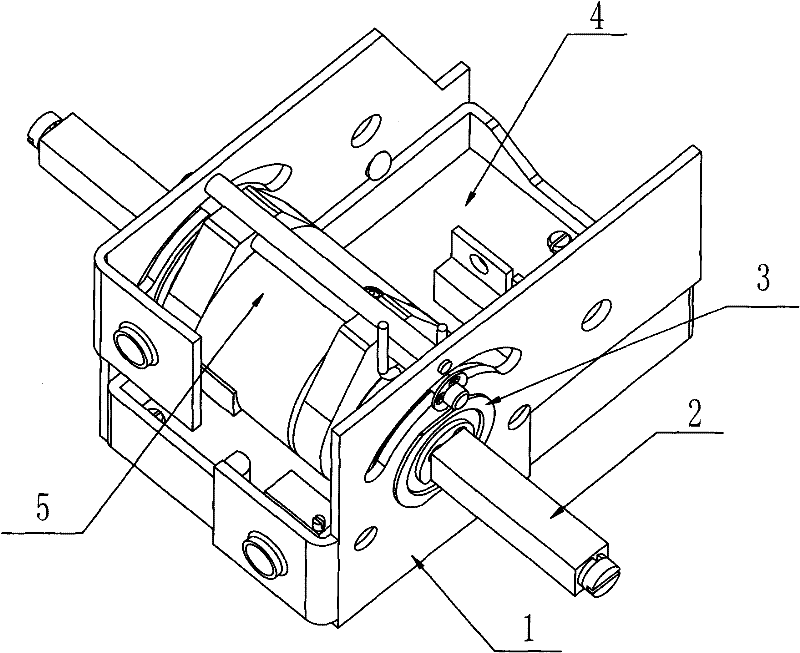

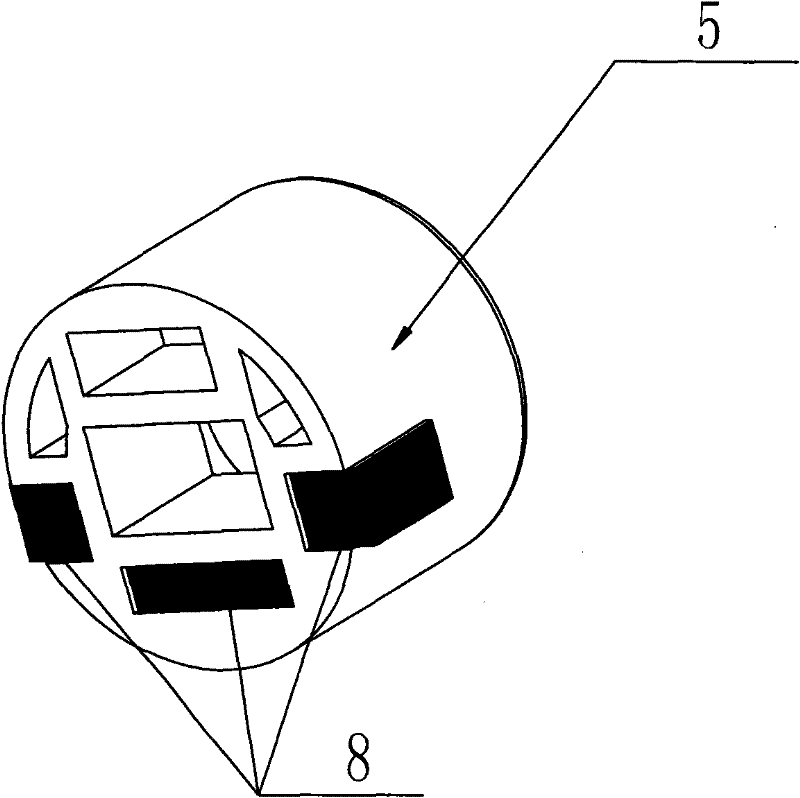

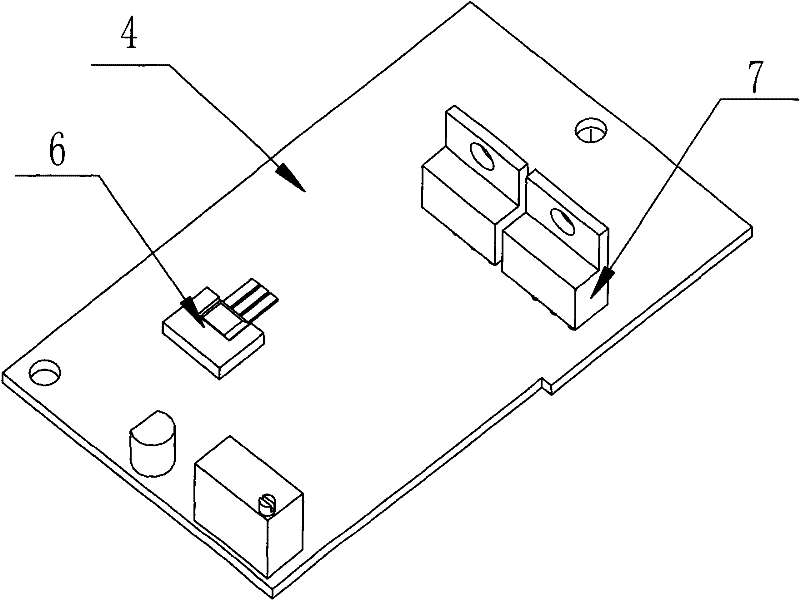

[0013] Such as figure 1 , figure 2 and image 3 The electronic governor device for an electric stacker vehicle includes a base 1, a square rotating shaft 2 is installed on the base 1, a magnetic steel assembly is arranged on the square rotating shaft 2, and a magnetic steel assembly is placed below the magnetic steel assembly. A PCB board 4 is provided, and a Hall sensor 6 is provided on the PCB board 4. The magnetic steel assembly includes a magnetic steel main body 5, and a magnetic steel 8 is respectively provided at the middle lower part and the left and right sides of the magnetic steel main body 5. The magnetic steel assembly also includes bushings 3 on both sides of the magnetic steel main body 5, and the PCB board 4 is also provided with a direction speed detection module 7, and the signal generated by the magnetic steel 8 and the Hall sensor 6 is transmitted to the direction speed detection module 7 , the direction speed detection module 7 transmits the detected si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com