A straight-through high-pressure rotary joint

A rotary joint, straight-through technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing elements, etc., can solve the problems of easy wear and leakage of seals, improve service life and volume efficiency, and reduce flow resistance. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

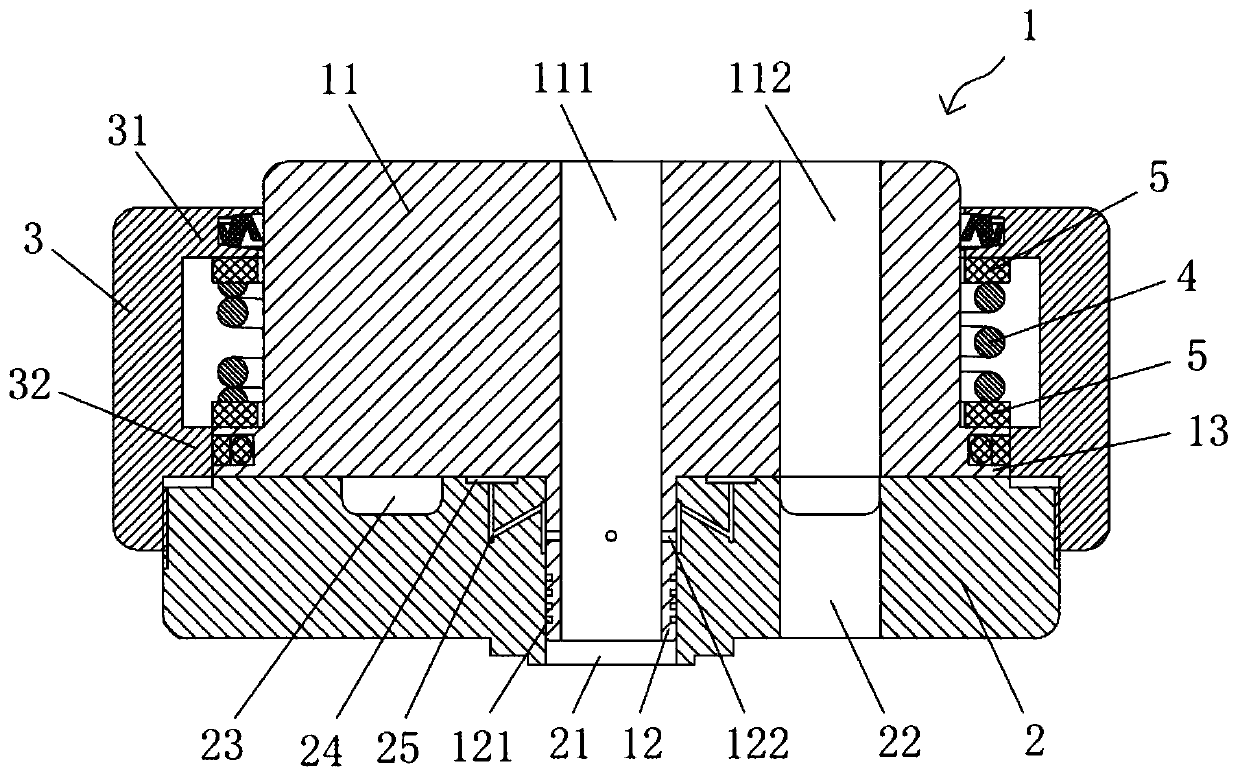

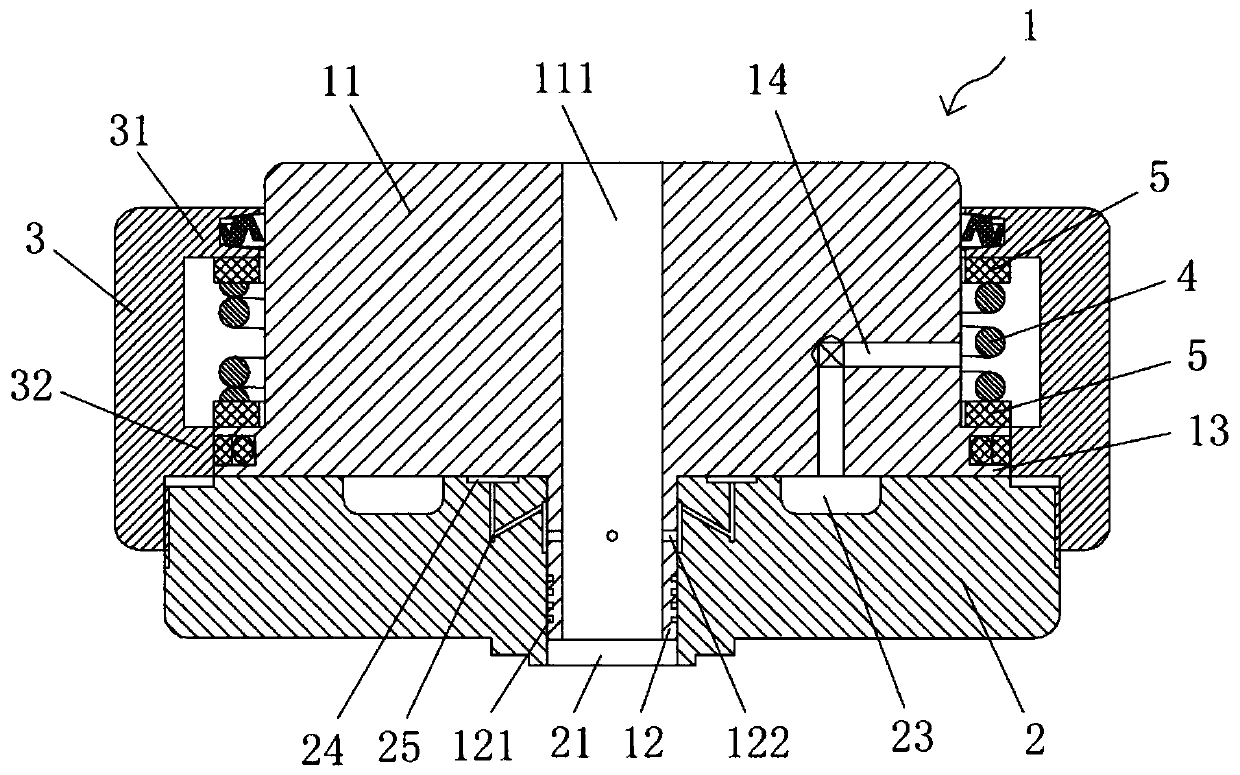

[0028] combine figure 1 As shown, the straight-through high-pressure rotary joint of the present invention includes an upper rotary body 1 , a lower rotary body 2 and a connecting piece 3 . Wherein, the upper rotating body 1 and the lower rotating body 2 can carry out relative movement in the axial direction and relative rotation in the circumferential direction under the connection effect of the connecting member 3 .

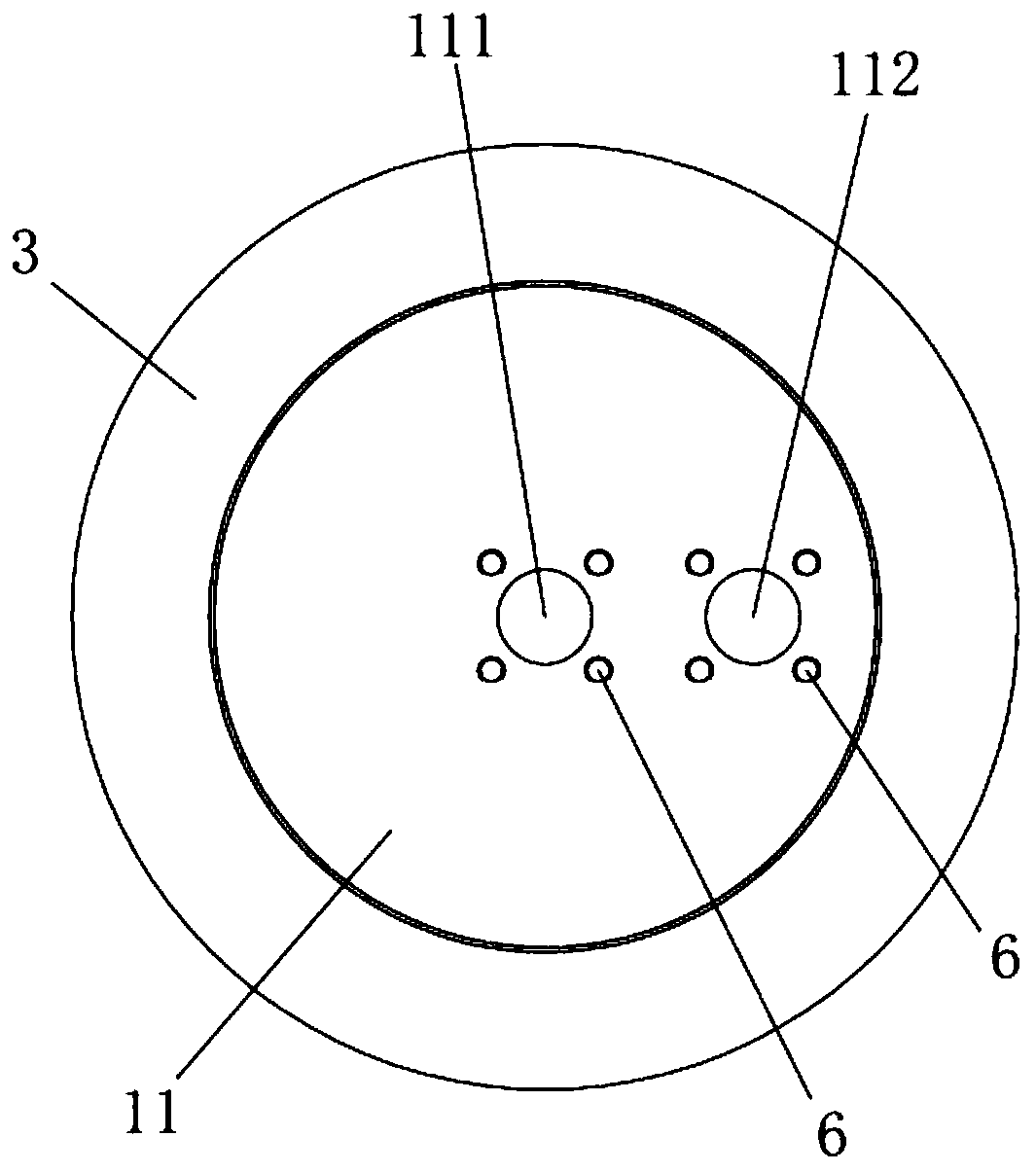

[0029] The upper rotating body 1 is a T-shaped structure, including a connecting end 11 located in the upper half and a guiding end 12 located in the lower half. Wherein, a high-pressure oil passage 111 and an upper oil passage 112 are provided on the upper surface of the connection end 11 . A high-pressure oil passage 111 runs through the connection end 11 and the guide end 12 along the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com