Sealing between a combustion chamber and a turbine distributor in a turbine engine

A technology of turbine nozzles and turbines, which is applied to the sealing of engines, gas turbine devices, mechanical equipment, etc., can solve problems such as increasing the risk of cracks, and achieve the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

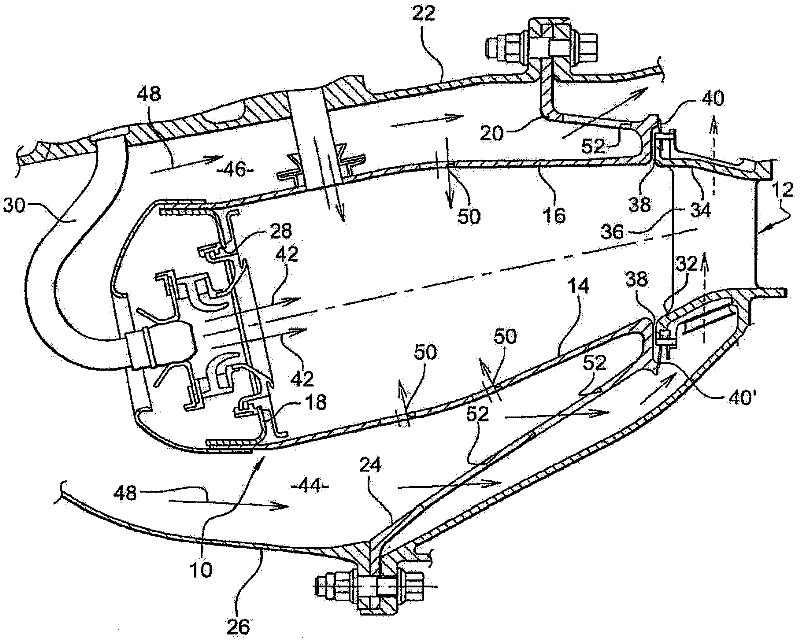

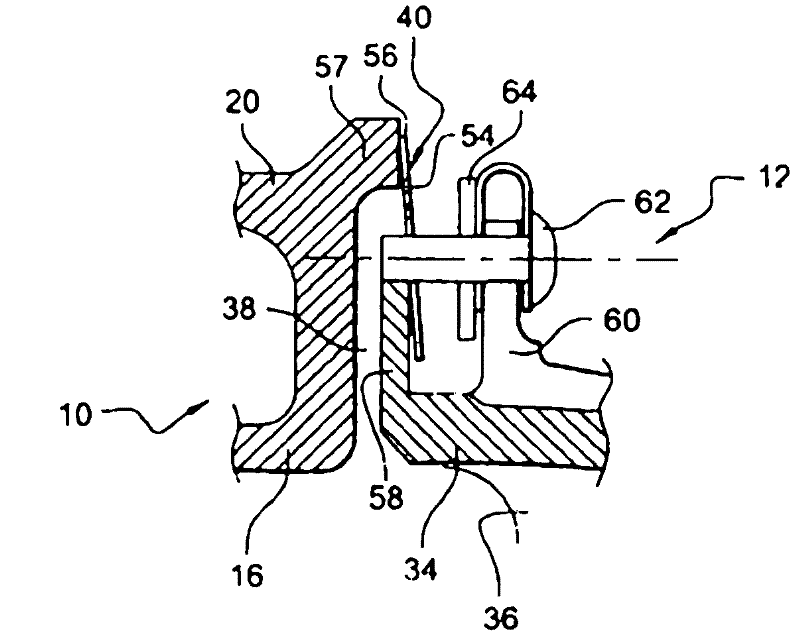

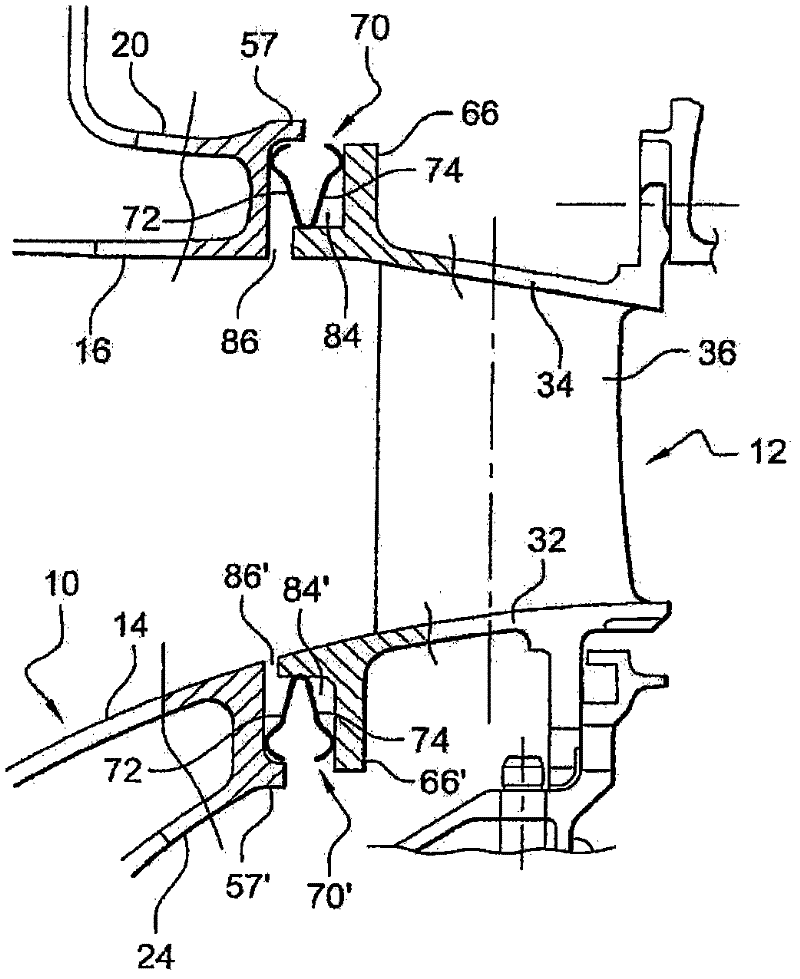

[0031] first reference figure 1 , figure 1 Shown is an annular combustor 10 of a turbomachine, such as an aircraft turboprop or turbojet, arranged downstream of a compressor and diffuser (not shown) and at the inlet nozzle 12 of a high pressure turbine 10 upstream.

[0032] The combustion chamber 10 has an inner wall 14 forming a surface of revolution and an outer wall 16 inside which the inner wall extends and which are connected together at the upstream end by means of an annular chamber end wall 18 . The outer wall 16 of the combustion chamber is connected at the downstream end to an outer annular flange 20 which is fastened at the outer periphery to the outer casing 22 of the combustion chamber, and the inner wall 14 is connected at the downstream end to an inner annular flange 24 which The rim 24 is fastened at the inner periphery to the inner casing 26 of the combustion chamber.

[0033] The annular chamber end wall 18 has an opening 28 for the passage of air from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com