Rear car triangle window assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below with reference to the accompanying drawings.

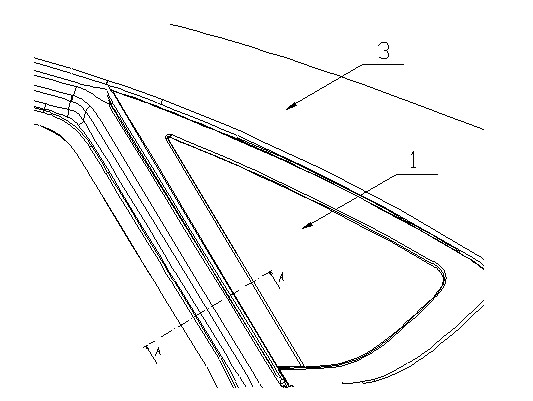

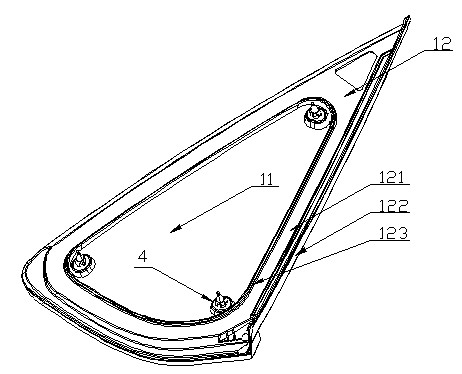

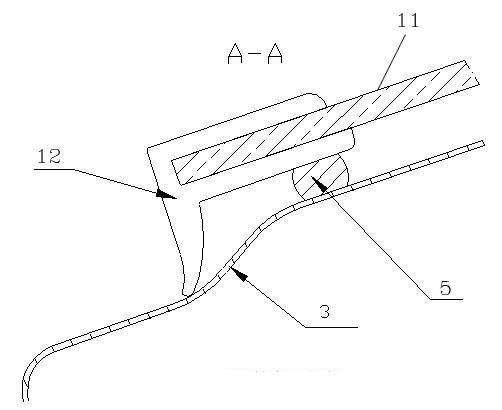

[0020] The automobile rear triangle window assembly structure that the present invention proposes is as follows figure 2 , the profile is as Figure 4 As shown, the automobile rear quarter window assembly 1 is composed of glass 11, wrapping 12, and positioning clip 4. The positioning clip is made of PA66, and the wrapping material is PVC. The positioning clip 4 is injected on the glass 11 by integral injection molding with the glass. On the inner surface, and form a wrapping 12 structure around the glass, which plays the role of protection and decoration. The injection-molded edging structure includes a lip 122 , a glue-applied surface 121 and a glue-holding groove 123 , and these structures are injection-molded at the same time without adding additional molds or processes. The lip 122 is designed according to the shape and appearance, and is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com