Backfilling process for large ultra-deep circulating water pipe

A technology for circulating water and pipelines, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of short service life and poor anti-corrosion performance, and achieve the effect of improving anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

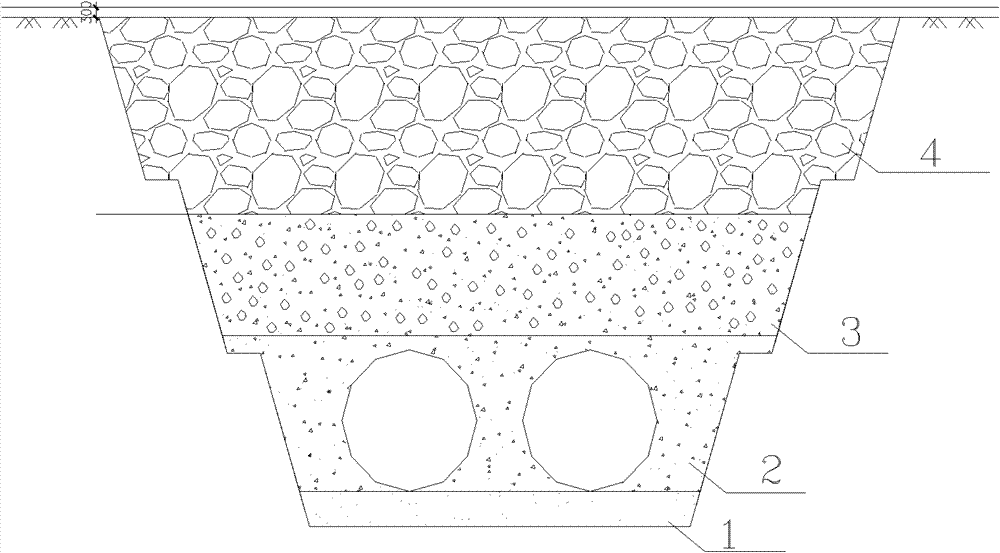

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] refer to figure 1 , a large-scale ultra-deep circulating water pipeline backfilling process, the backfilling process includes the following steps:

[0021] (1) Sand cushion construction:

[0022] The thickness of the sand cushion layer is 1000-1500mm, and the material is medium-coarse sand and coarse sand. The construction process is as follows: measure the elevation of the base → check and accept the foundation trench → release the edge line → cut the material → pave and distribute → shake with a flat vibrator after watering → sand Density sampling test;

[0023] (2) Concrete wrapping

[0024] The thickness of the concrete layer is 4000-5500mm, and the circulating water pipe is placed on the sand cushion layer. The construction process is: axis and elevation review → sample proofreading → concrete formwork production → formwork reinforcement → concrete blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com