Flake absorbing mechanism for automatic flaker

A technology of automatic film wrapping machine and swing mechanism, which is applied to conveyor objects, transportation and packaging, electrode manufacturing, etc., can solve the problem of inability to meet the needs of automatic film wrapping machine, etc., and achieve the effect of reliable suction plate and accurate release position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

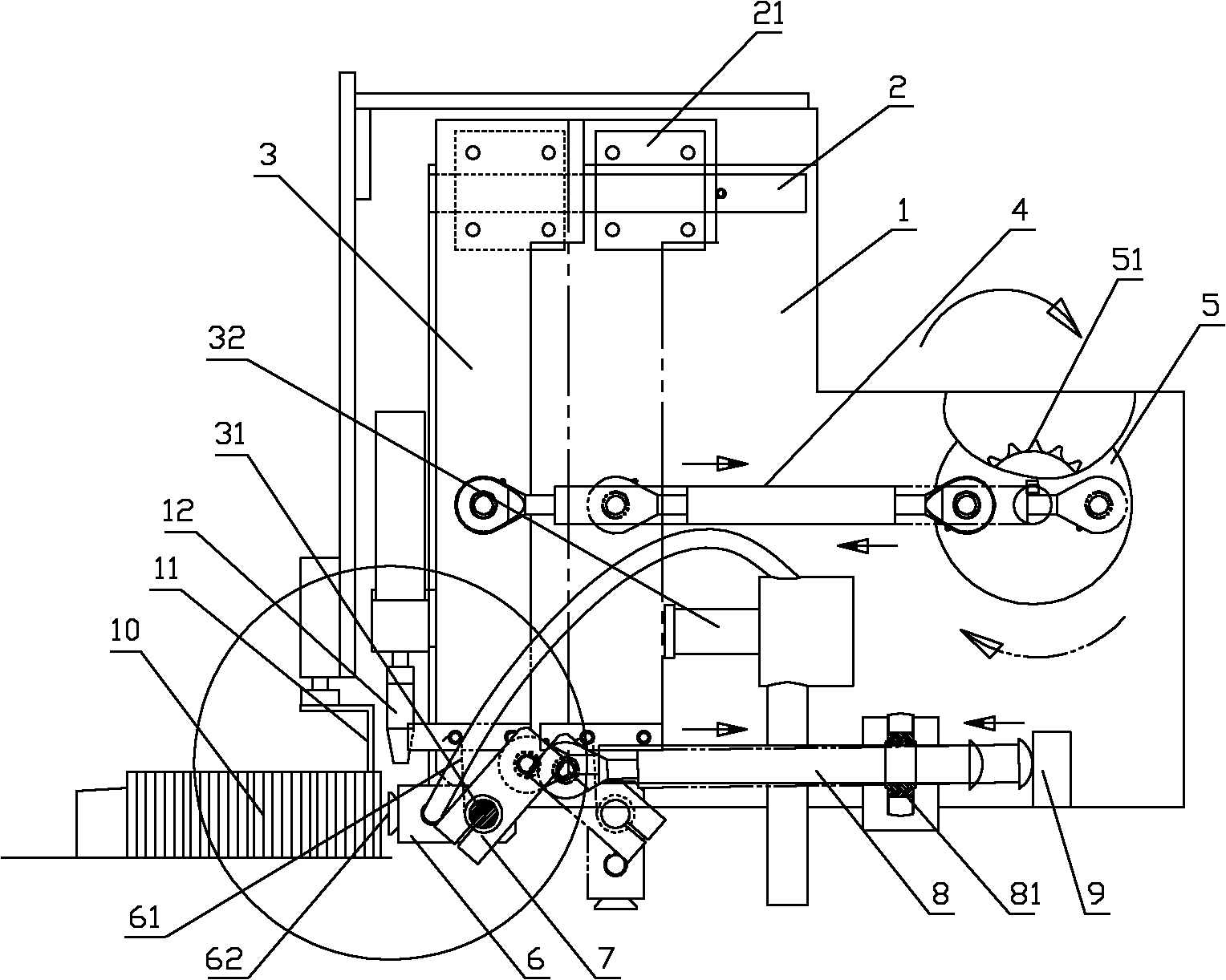

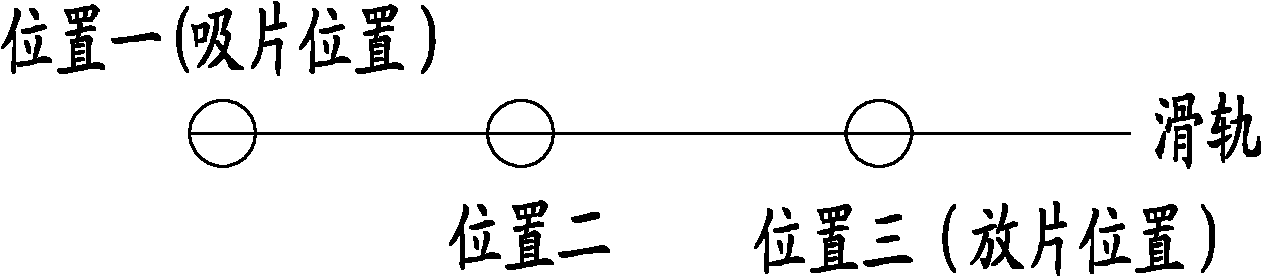

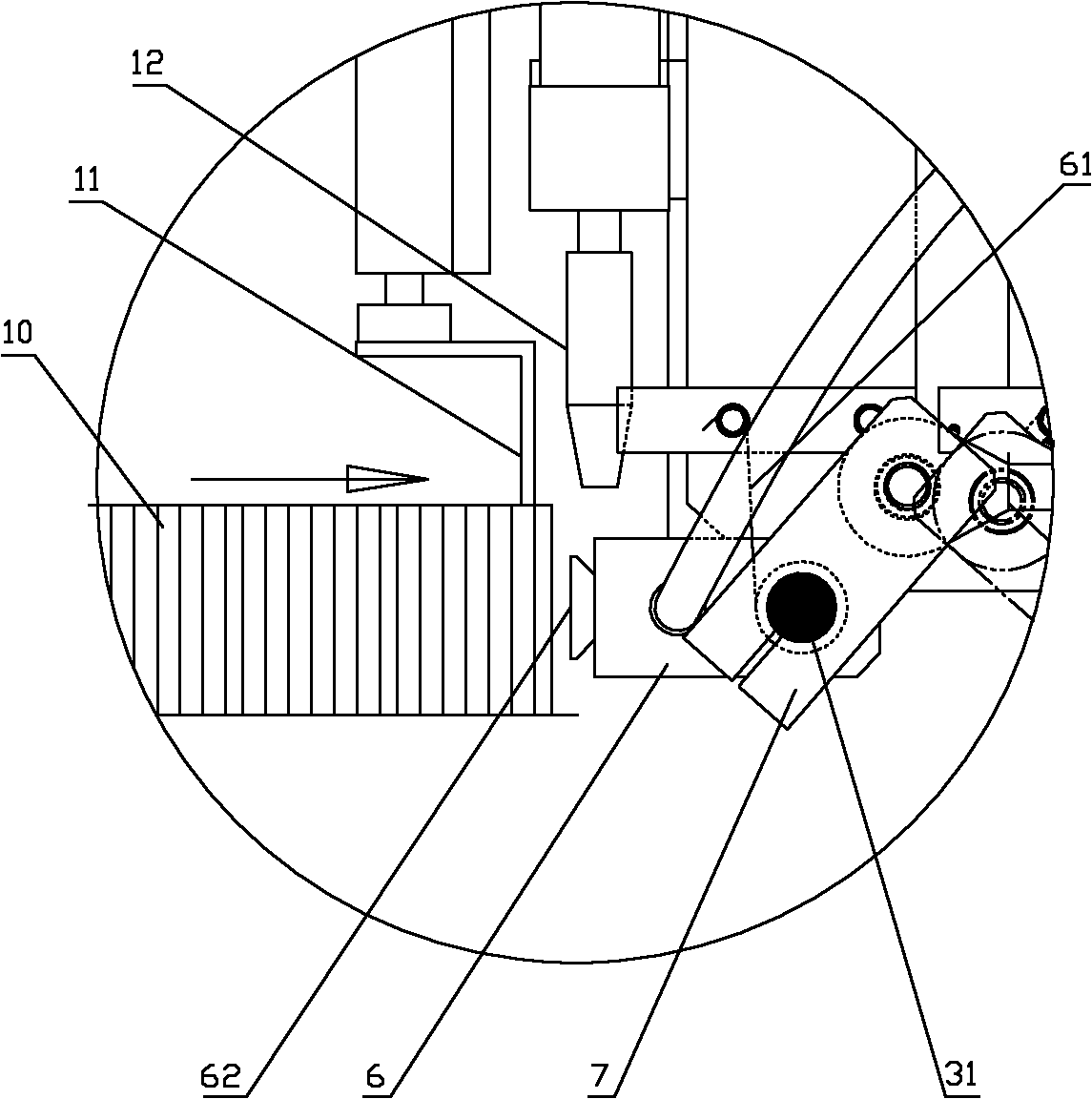

[0017] Such as figure 1 and figure 2 As shown, it is an embodiment of the suction mechanism of the automatic wrapping machine of the present invention, which includes a plate-shaped body 1, a horizontal slide rail 2 is arranged above the body, and a vertical moving rod 3 is slidably connected to the slide rail. The middle part of the moving rod is connected with a rocker mechanism to drive the moving rod to do reciprocating linear motion along the slide rail. The lower end of the moving rod is connected to the suction cup seat 6 through the fixed shaft 31. The suction cup seat is provided with a suction cup 62, and the fixed shaft is connected to the suction cup. Seat swing mechanism, the suction cup seat swing mechanism cooperates with the linear motion of the moving rod to drive the suction cup seat to switch between the horizontal sheet suction state and the vertical sheet release state. The rocker mechanism includes an eccentric wheel 5 arranged on the body, the eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com