Electromagnetic regulator

A technology for adjusting equipment and electromagnetism. It is applied to electromagnets, mechanical equipment, electromagnets with armatures, etc. It can solve problems such as shortening lifespan, and achieve the effects of reducing friction, unobstructed rotation, and reducing material wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

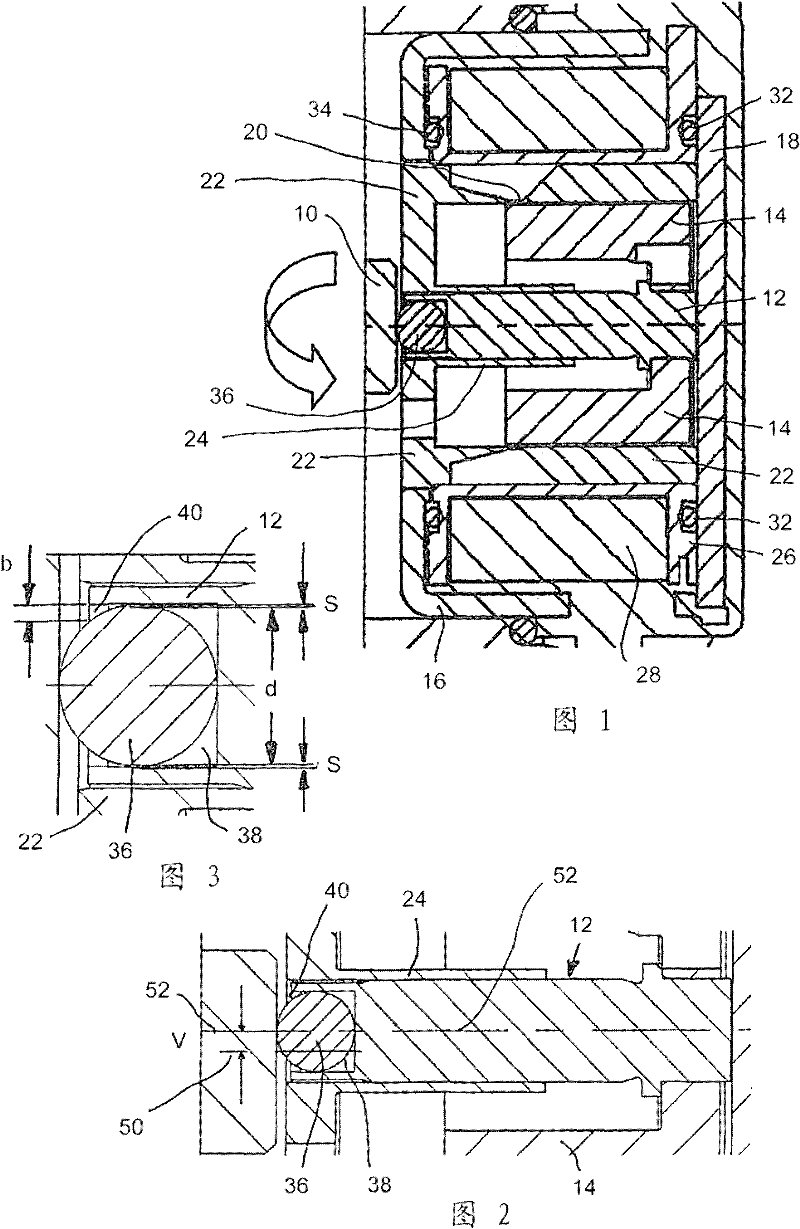

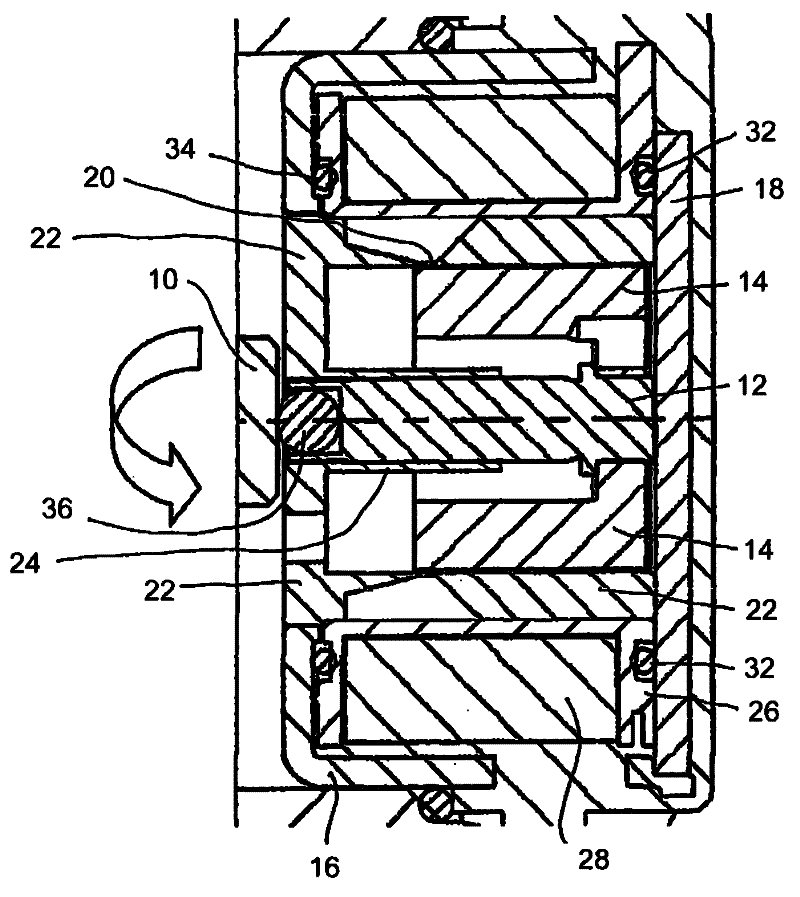

[0018] figure 1 The principle structure and the periphery of an electromagnetic adjusting device according to a first preferred embodiment, which is mounted via a camshaft adjustment of an internal combustion engine shown only schematically in section ( Not shown) pressure on the valve slide 10 of the switching valve unit to adjust the camshaft.

[0019] Linear thrust (at figure 1 Axial to the left in the drawing) is applied to the valve slide unit 10 by the plunger unit 12, which is part of the armature unit of the electromagnetic adjustment device shown and is connected to the cup-shaped armature The parts 14 cooperate to form an armature unit movably guided inside a two-piece housing made of a housing shell 16 and a housing bottom 18 . Strictly speaking, the armature units 12, 14 are surrounded by a yoke core unit 22 in this embodiment, which is integrally formed with a centrally located, conically tapering on both sides, in order to form a magnetic circuit. The middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com