Polishing nose

A machine head and headstock technology, which can be used in grinding machines, abrasive belt grinders, grinding/polishing equipment, etc., can solve the problems of raising dust, reducing grinding ability, and not being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

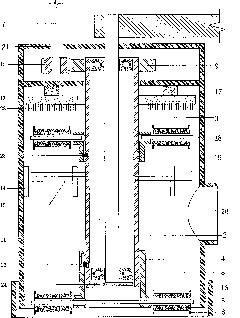

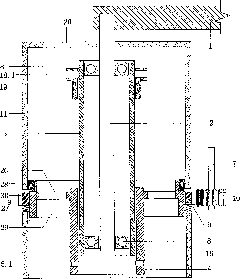

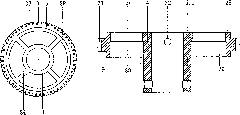

[0118] 1. According to the grinding object, determine the size of the machine head, the circumference and width of the circulating belt and the emery cloth belt, and the power.

[0119] If the selected cycle belt is longer, the abrasive cloth belt will wear slowly, the number of replacements will be less, and the work efficiency will be high. But the longer the endless belt, the bigger the distance between the upper and lower abrasive belt shafts, the longer the corresponding mandrel and cylinder shaft, and the higher the head body. When the head is raised, the center of mass rises, and the head is prone to shake during grinding. Therefore, when choosing the solution in this example, the height of the nose should be appropriate.

[0120] 2. Select the power supply method, the installation position of the driven gear, the speed regulation of the circulating belt, the installation position of the brush, etc., which will affect the structure of the machine head. The installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com