Live working R-type pin remover

A technology of live work and pin remover, which is applied to overhead line/cable equipment, hand-held tools, manufacturing tools, etc., can solve the problems of replacement and insulator failure, and achieve the effect of improving smoothness, convenient reset, and avoiding shaking and swinging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

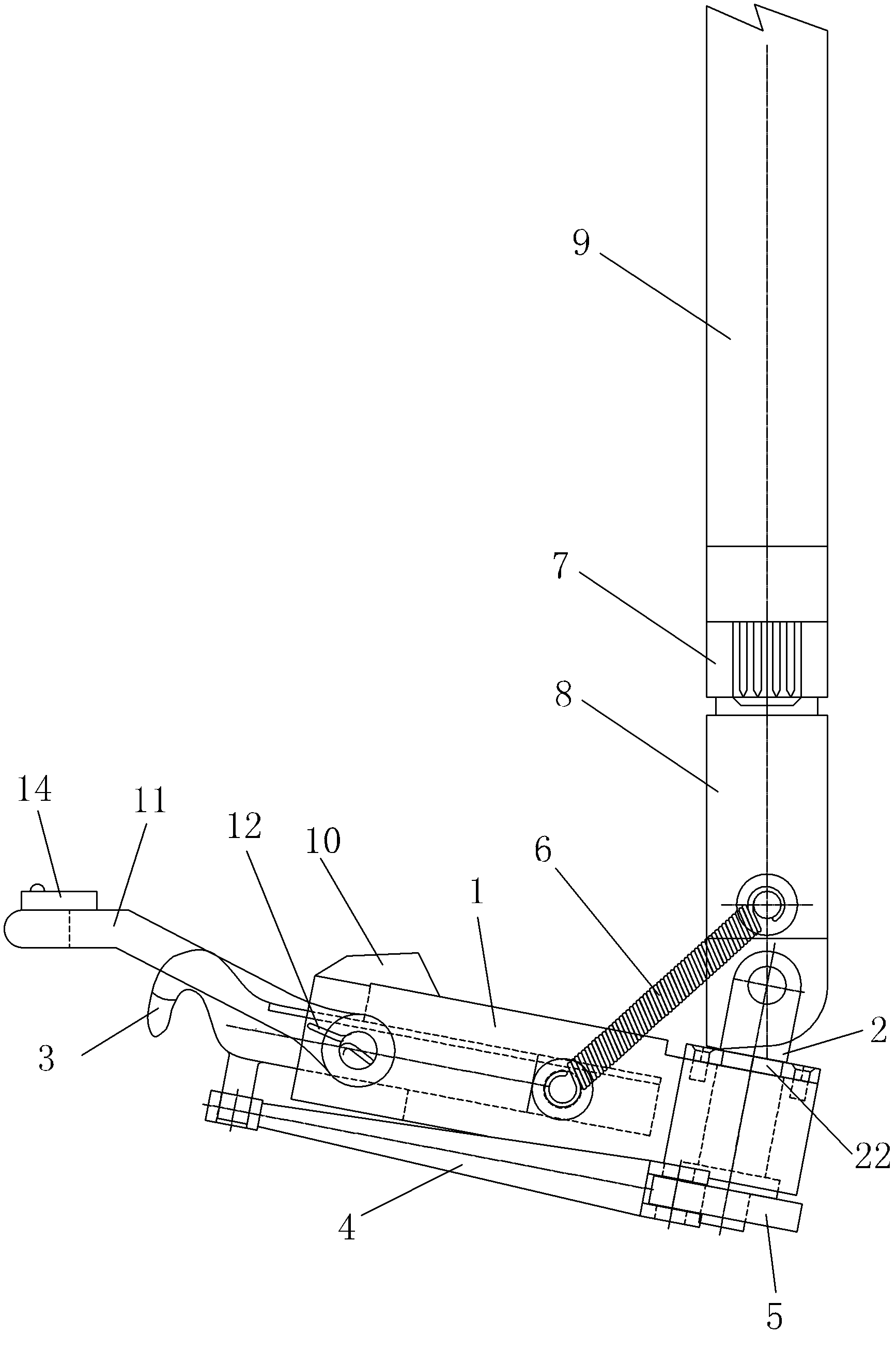

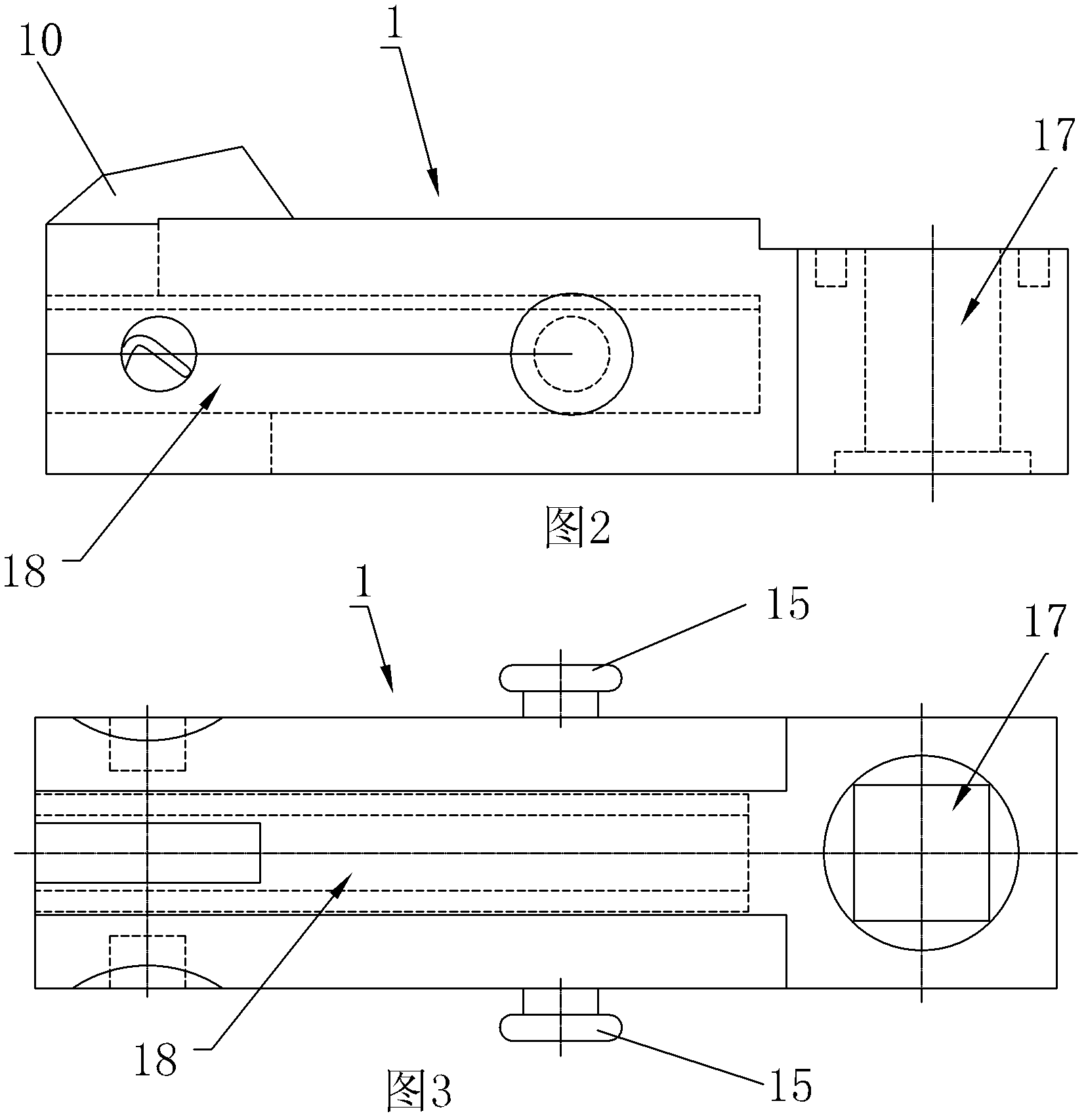

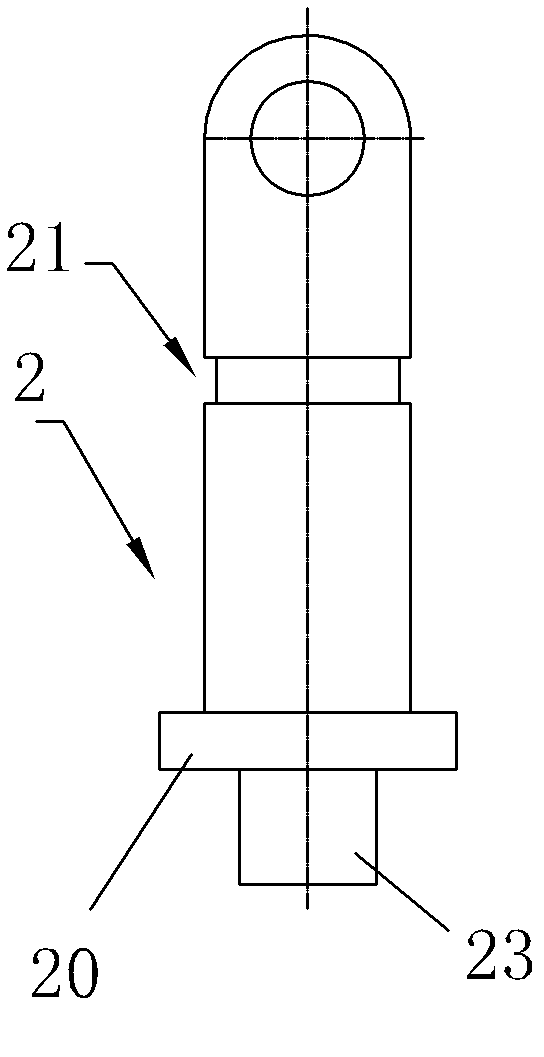

[0031] Example: R-type pin remover for live work, such as figure 1 As shown, it includes a base 1 provided with a rotating socket 17 at one end and a guide groove at the other end, an interlocking shaft 2 inserted in the rotating socket, a pin removal head 3 matched with the guide groove, one end is connected with the pin removal head 3, the other A transmission rod 4 connected to the interlocking shaft 2 through a shaft connecting plate 5 at one end, an operating rod assembly pivotally connected to the interlocking shaft 2 , and a tension spring 6 connecting the base 1 and the operating rod assembly. like figure 2 As shown, a spacer block 10 is provided on the top surface of the end of the base 1 where the pin-removing head 3 is provided.

[0032] like figure 1 As shown, the operation lever assembly includes an operation support rod 7 pivotally connected with the linkage shaft 2, a sleeve 8 sleeved on the periphery of the middle section of the operation support rod 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com