Friction pendulum array shock insulation layer with overall consistency of curvature of slide grooves

A friction pendulum, consistent technology, applied in the direction of earthquake resistance, building type, building components, etc., can solve the problem of poor isolation effect, and achieve the effect of enhanced isolation effect, simple structure, and easy production and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

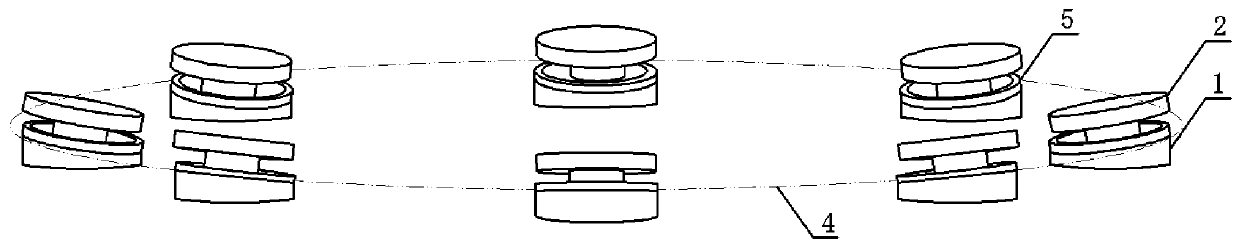

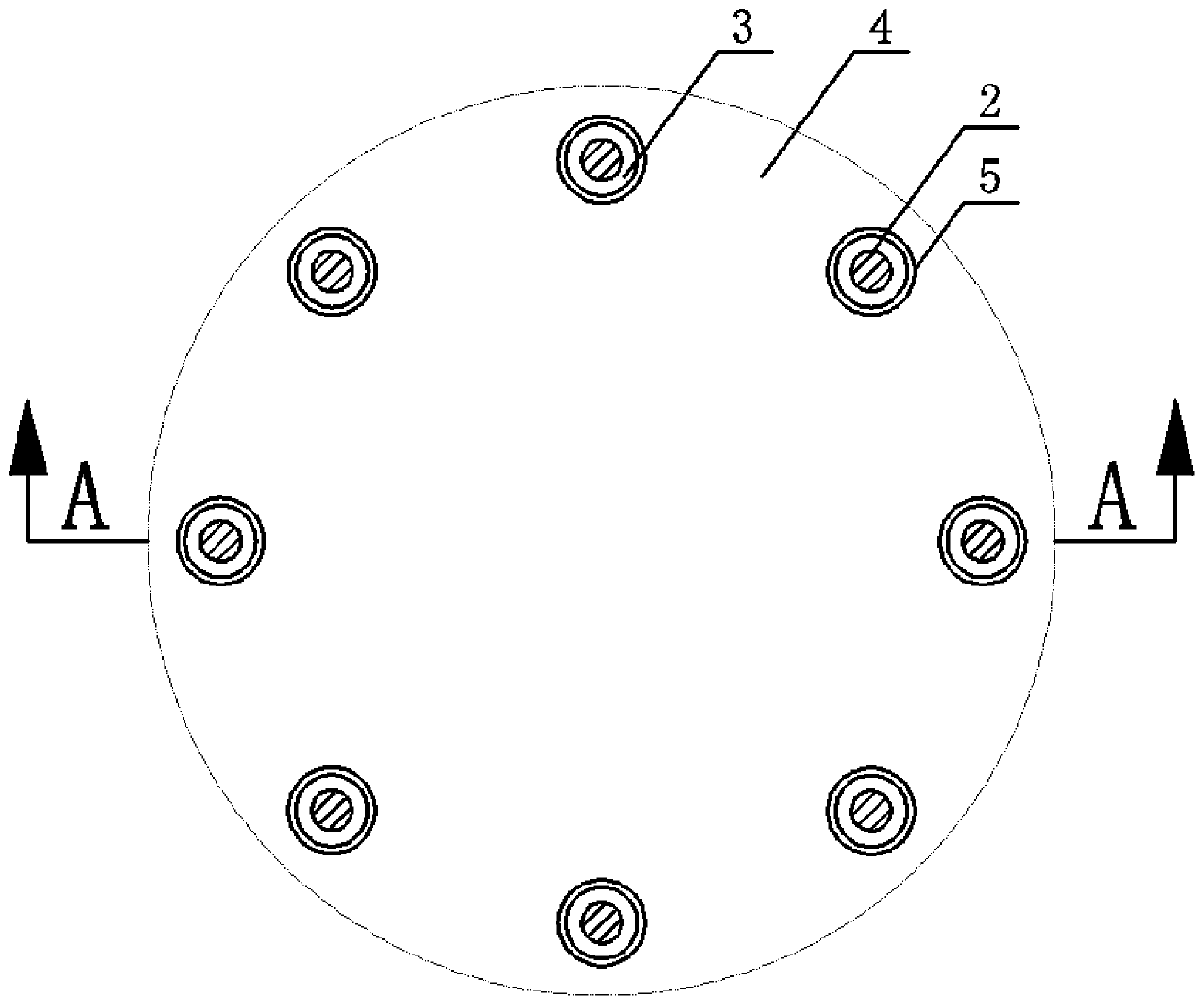

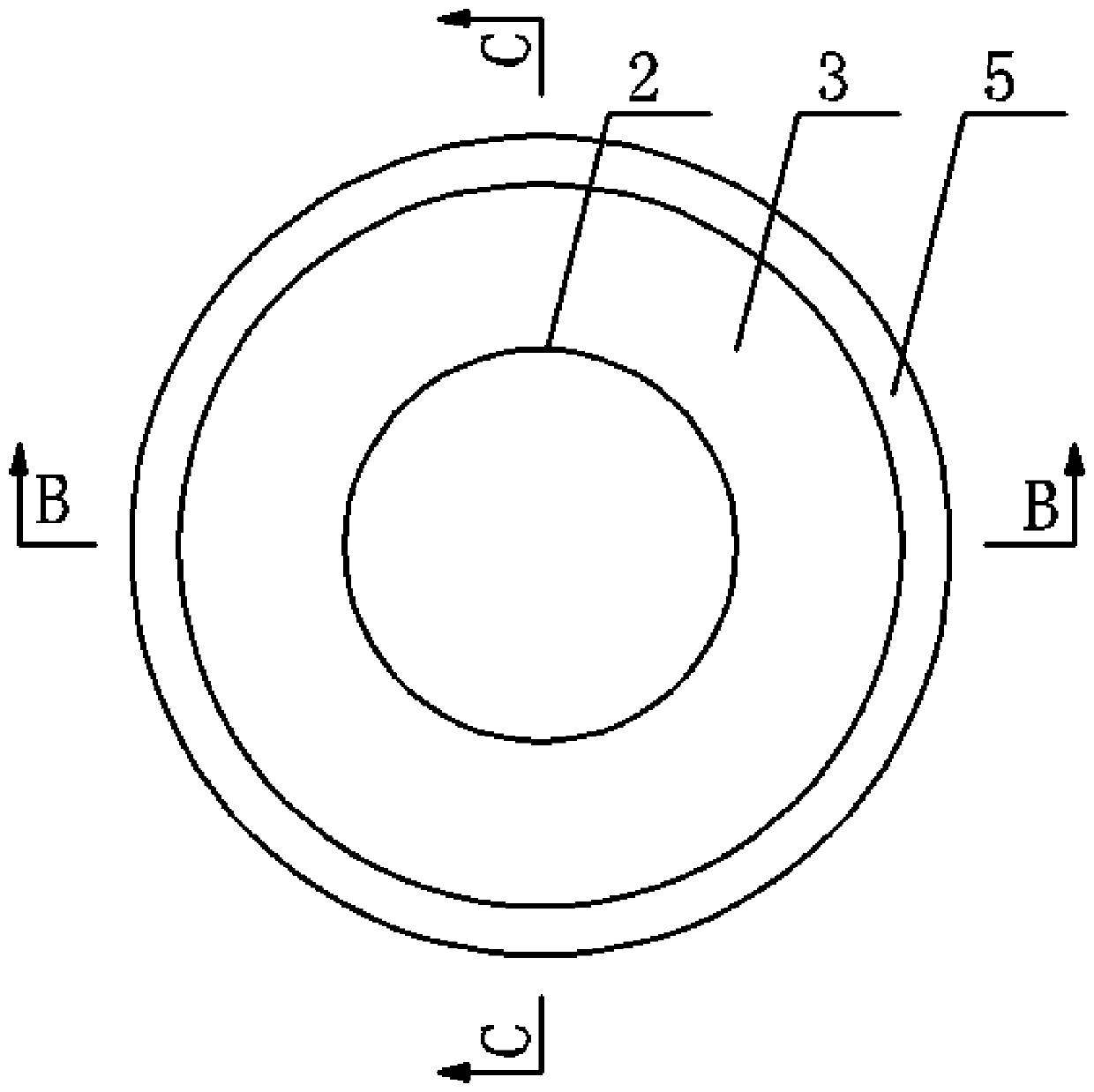

[0016] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, the vibration isolation layer of a friction pendulum array with the same curvature of the chute as described in this embodiment includes a plurality of integrated friction pendulum isolation supports, and the plurality of integrated friction pendulum isolation supports are circular The shape is evenly distributed, and each of the integrated friction pendulum shock-isolation bearings includes a bearing chute 1 and a bearing sliding plate 2, and the bearing sliding plate 2 is installed on the bearing chute sliding surface 3 of the bearing chute 1. The support chute sliding surfaces 3 of the support chute 1 of the integrated friction pendulum shock-isolation support are located on the same virtual surface 4 of curvature.

[0017] In this embodiment, since the support chute 1 conforms to the overall consistent type, each friction pendulum support in the isolation layer is installe...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, the sliding surface 3 of the support chute 1 of the support chute 1 of the friction pendulum array shock-isolation layer with the same chute curvature as a whole is provided with an annular baffle 5 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, the support slide plate 2 of a vibration-isolation layer of a friction pendulum array with the same chute curvature as a whole in this embodiment is made of stainless steel. In this embodiment, the size design of the support slide 2 is mainly determined according to the weight of the upper structure, so as to ensure that the support slide 2 has sufficient strength under pressure and can slide freely in the support slide 1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com