Manufacture method of trundle protection frame

A manufacturing method and technology of a protective frame, applied to frames, other household appliances, household appliances, etc., can solve problems such as peeling, damage, and inability to stabilize the plastic shell, and achieve the effect of strengthening the support and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

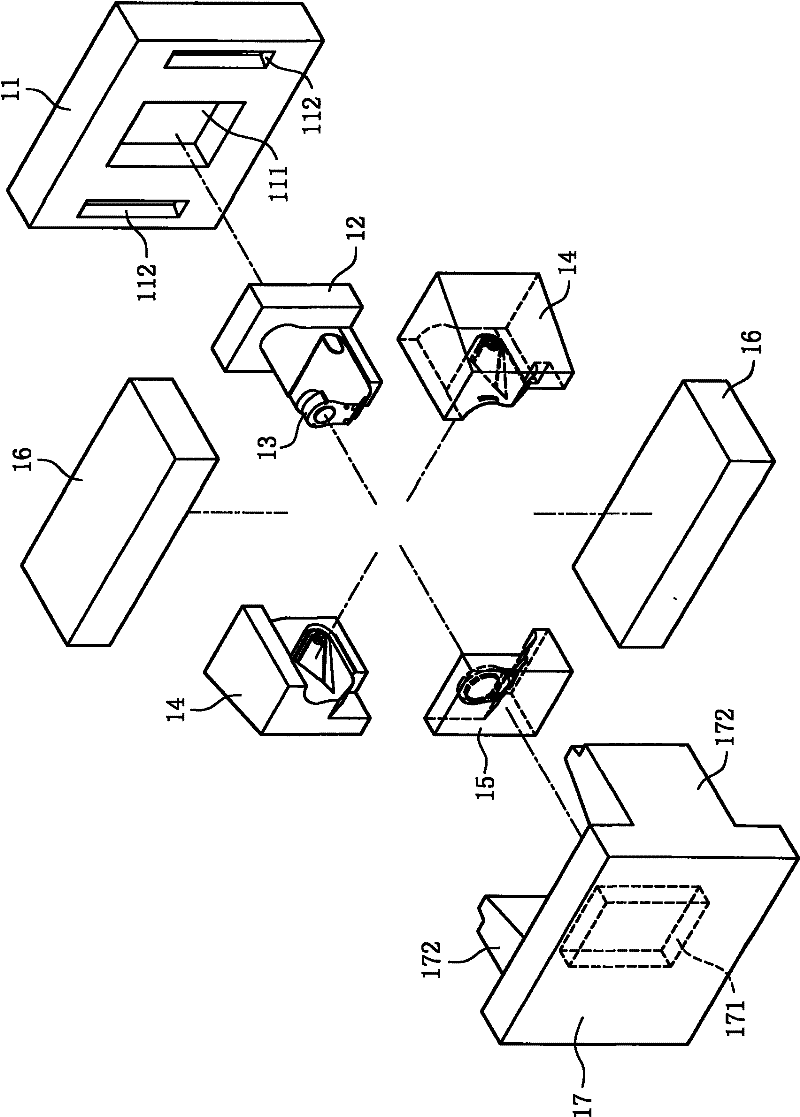

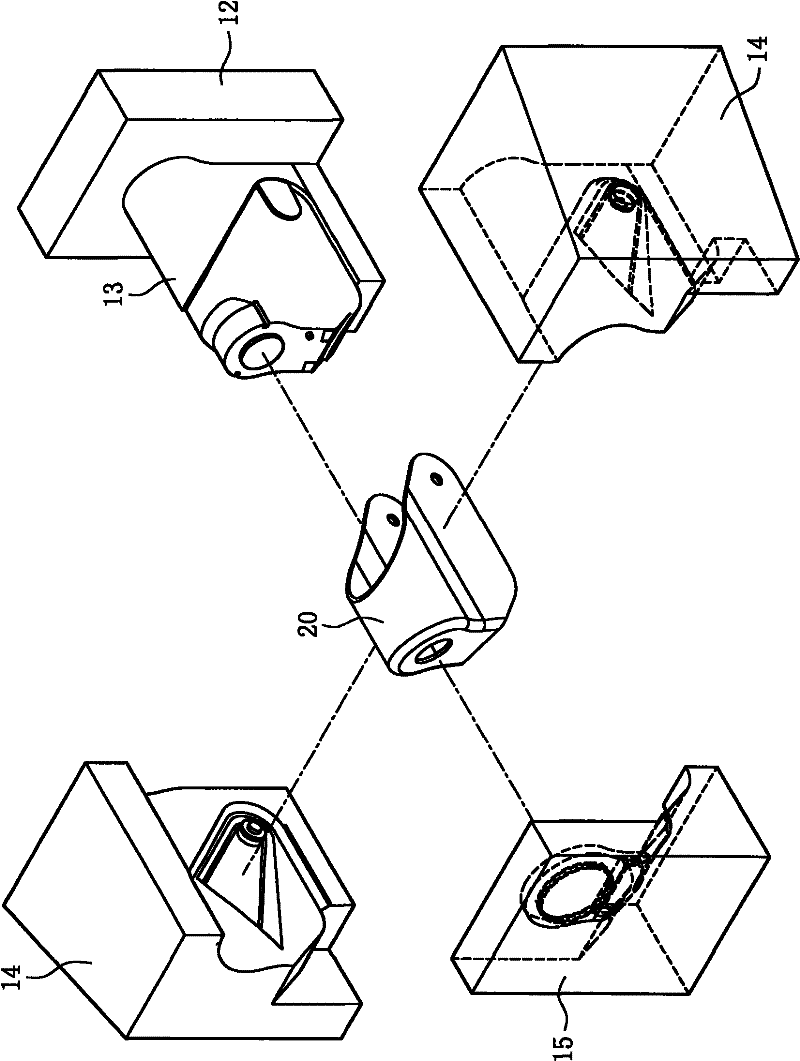

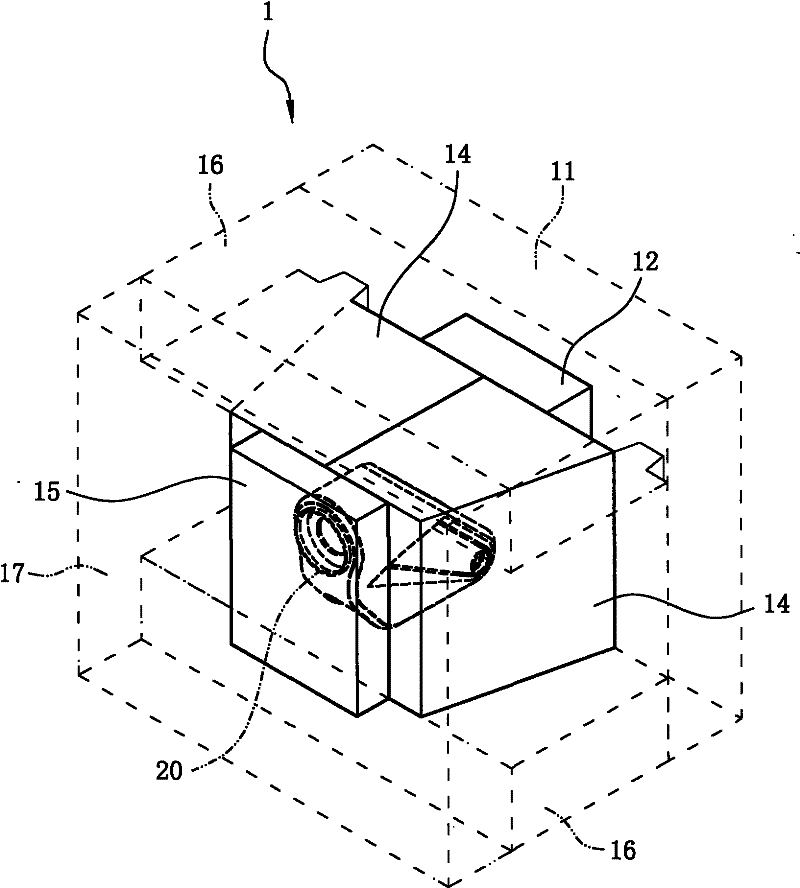

[0024] see Figure 1 to Figure 5 Shown are the schematic diagrams of Step 1 of the present invention, the schematic diagram of Step 2 of the present invention, the schematic diagram of Step 3 of the present invention, the schematic diagram of Step 4 of the present invention and the perspective state schematic diagram of the protective frame of the present invention after forming. As shown in the figure: a manufacturing method of a caster protective frame of the present invention, it comprises the following steps:

[0025] Step 1: Take a mold 1, the mold 1 includes a fixed seat 11, a base 12 placed on the fixed seat 11, a bearing part 13 extended on one side of the base 12, corresponding to the two sides of the bearing part 13 respectively The side formwork 14 on the side, the upper formwork 15 corresponding to the top of the bearing part 13, the pressing plate 16 abutting against each side formwork 14 end faces respectively, and a combined upper formwork 15, side formwork 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com