Printer

A technology for printers and platen rollers, applied in printing devices, printing and other directions, can solve problems such as poor operability, and achieve the effects of easy loading and unloading operations, improved operability, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

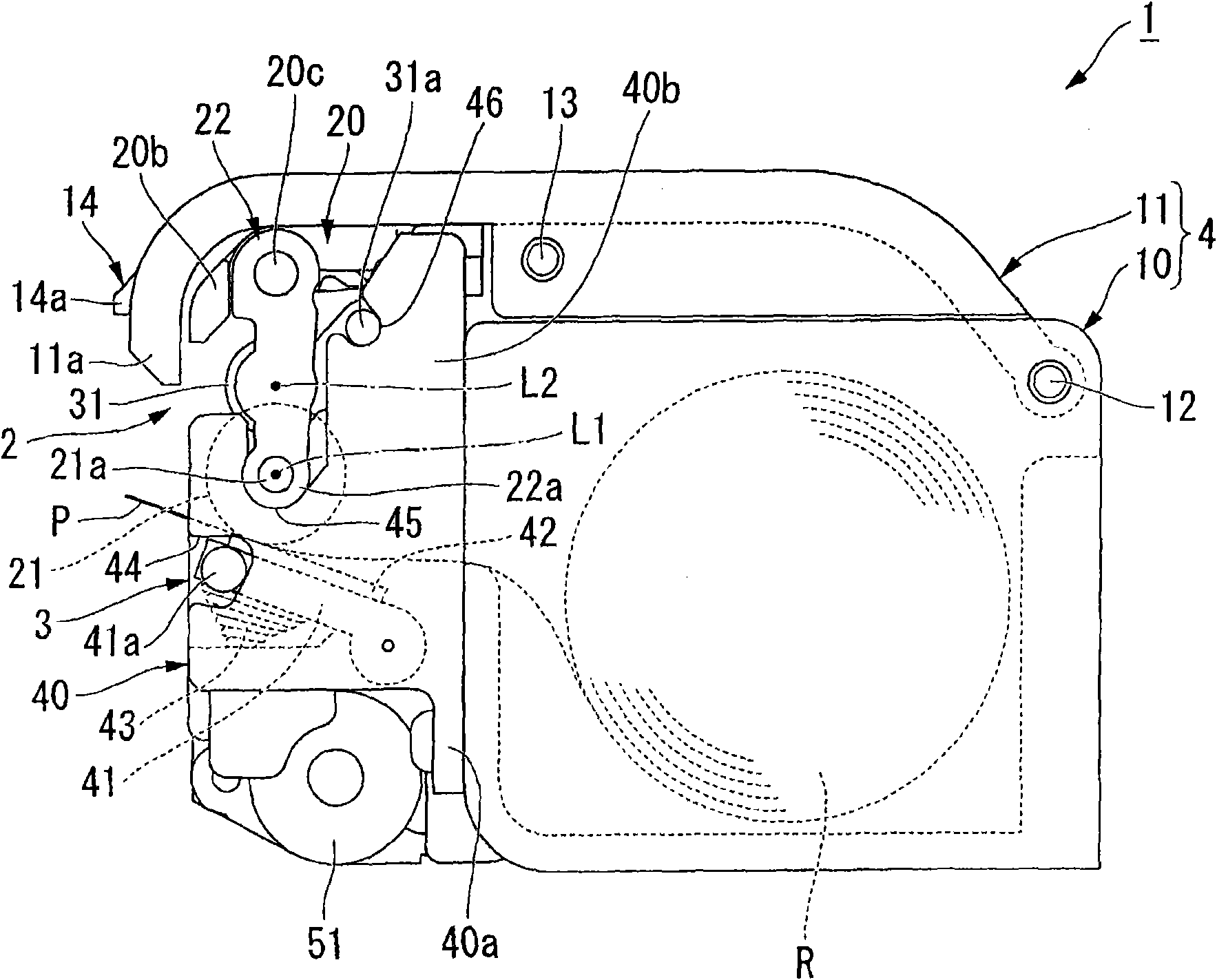

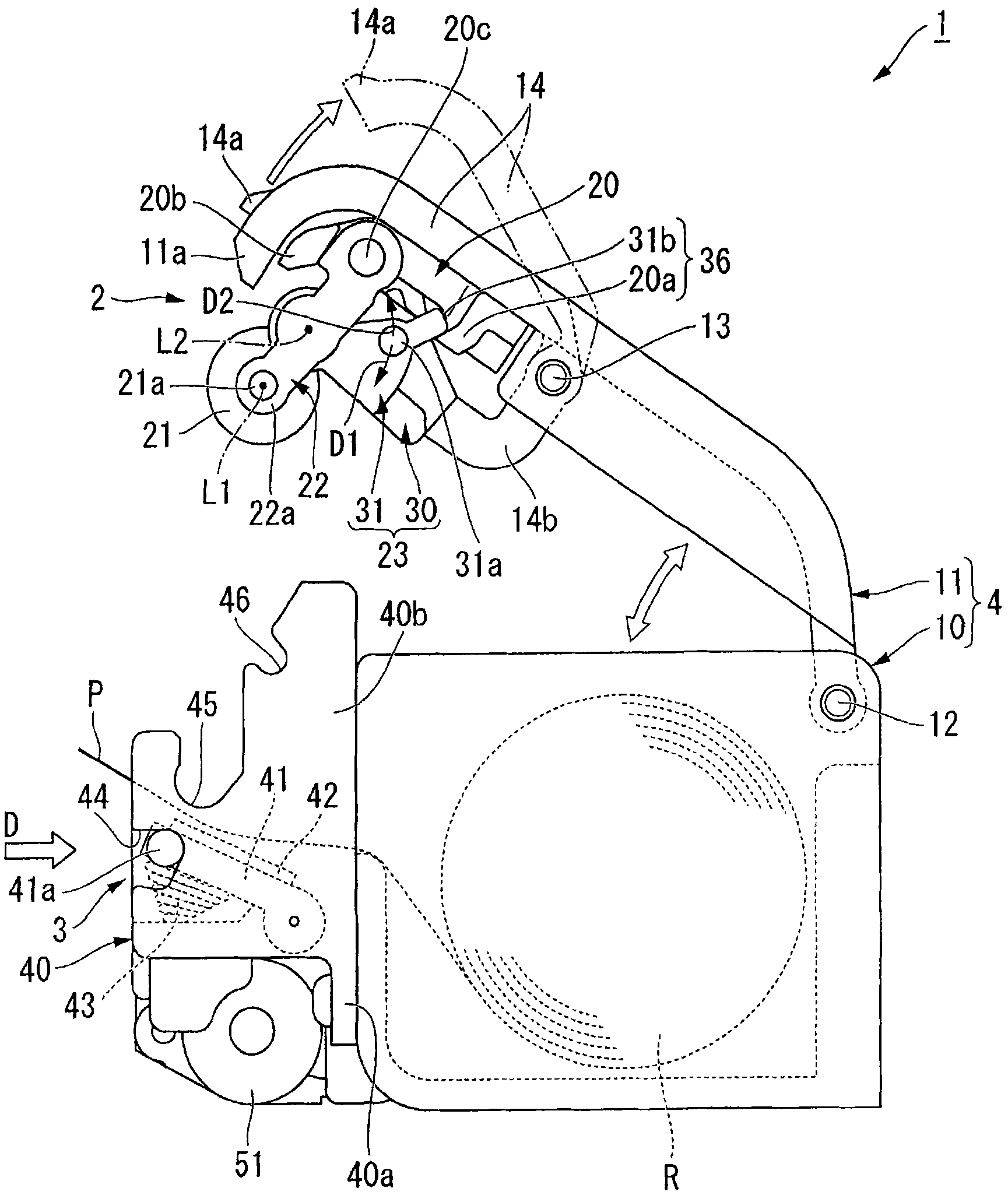

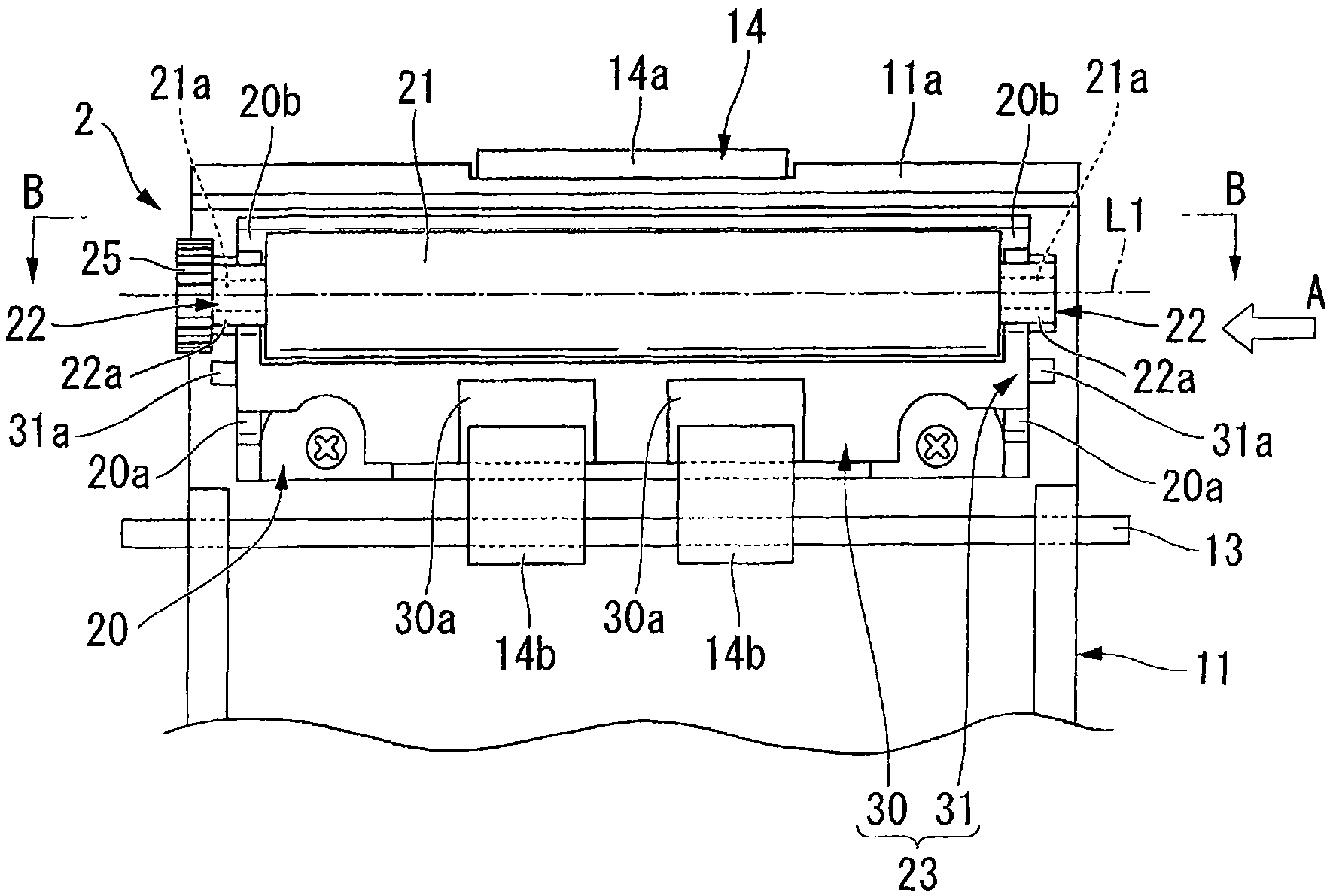

[0074] Below, refer to Figure 1 to Figure 14 , to describe the embodiment of the present invention. In addition, in this embodiment, as an example of a printer, a thermal printer will be described as an example.

[0075] Such as figure 1 and figure 2 As shown, the printer 1 according to the present embodiment includes a platen unit 2 and a main body unit 3 which are detachably combined, and a case 4 which accommodates a roll paper R around which recording paper P is wound.

[0076] also, figure 1 It is an overall side view of the printer 1 in a state where the platen unit 2 and the main body unit 3 are combined. figure 2 is displayed from figure 1 The shown state is an overall side view of a state where the paper platen unit 2 and the body unit 3 are separated.

[0077] First, the housing 4 will be described.

[0078] The case 4 of the present embodiment is constituted by a base member 10 and a lid member 11 that is openably and closably (rotatably) coupled to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com