Patents

Literature

31results about How to "Achieve finer diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

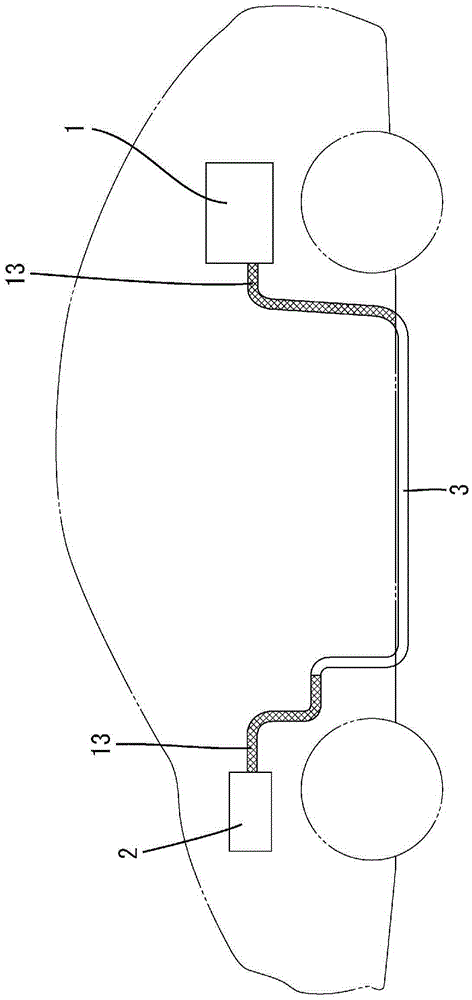

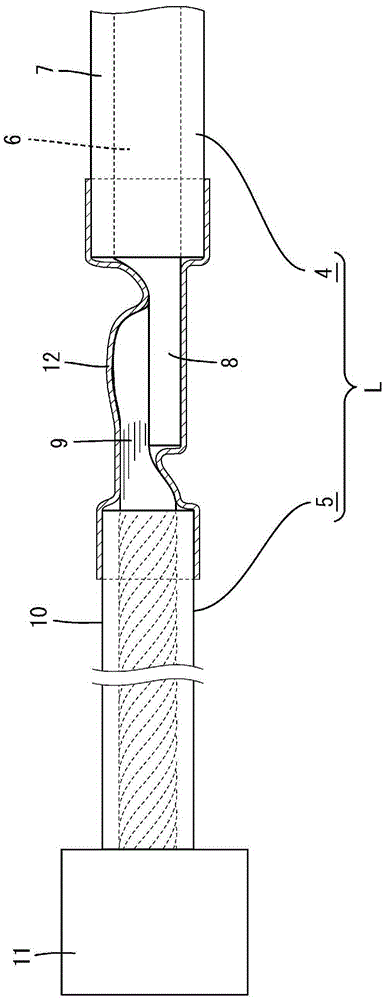

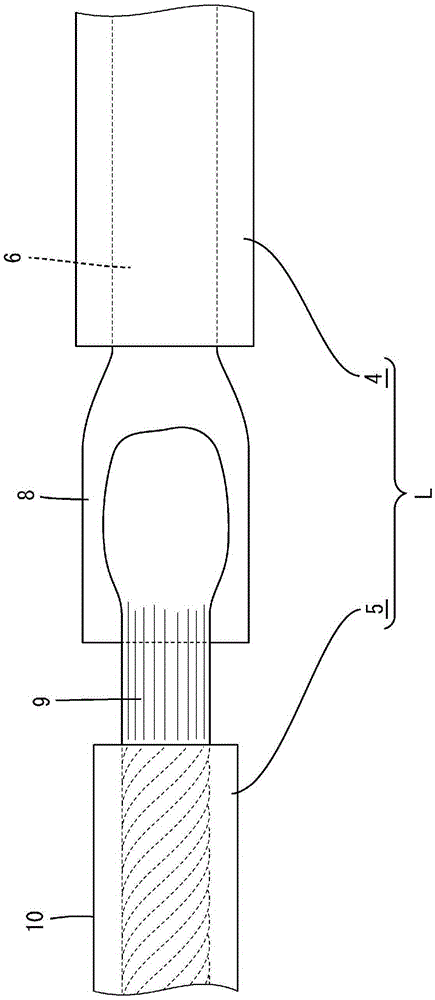

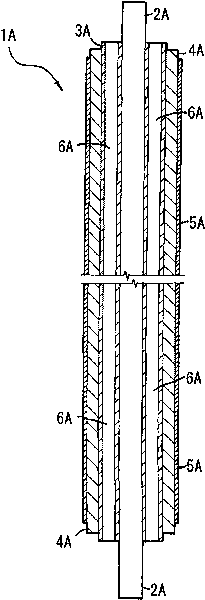

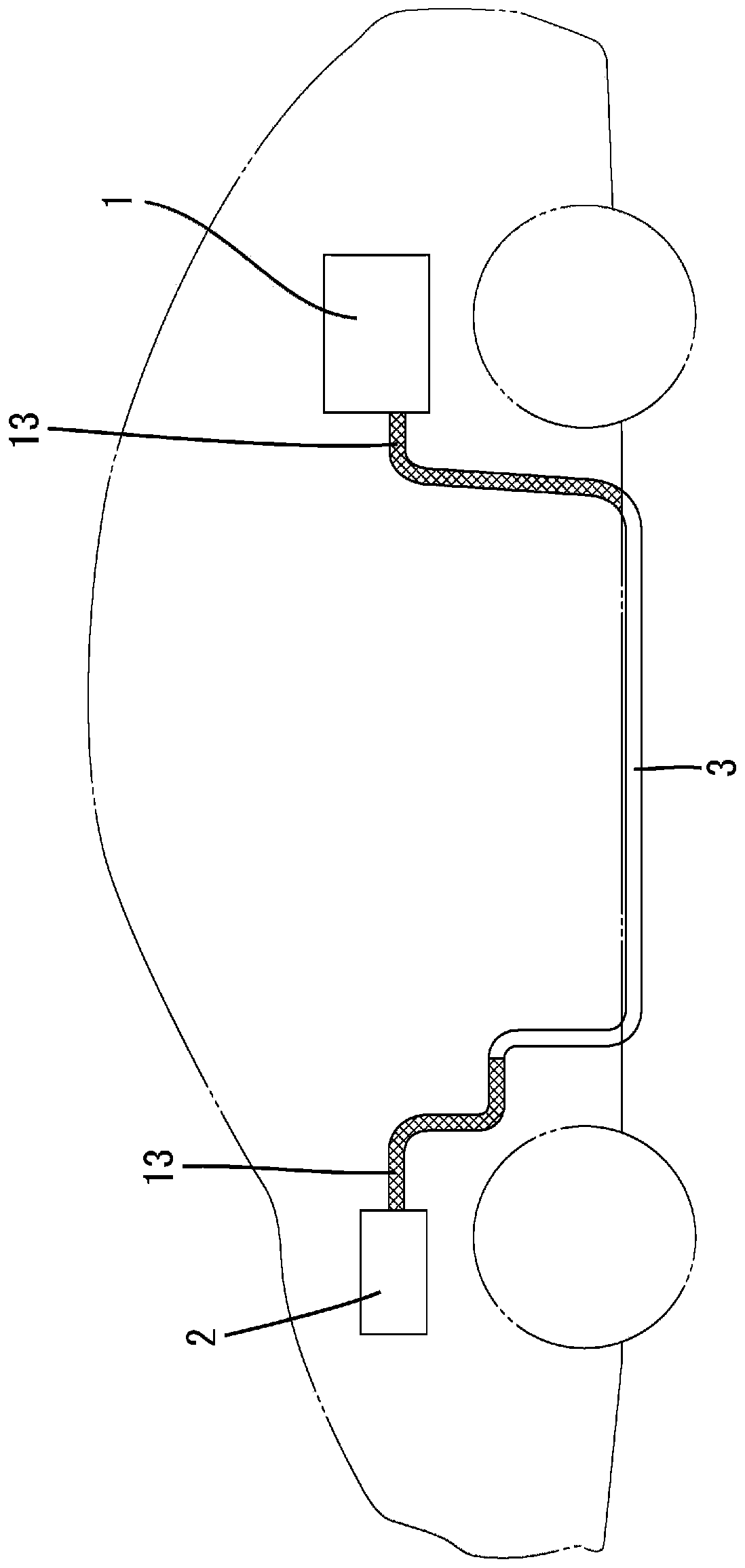

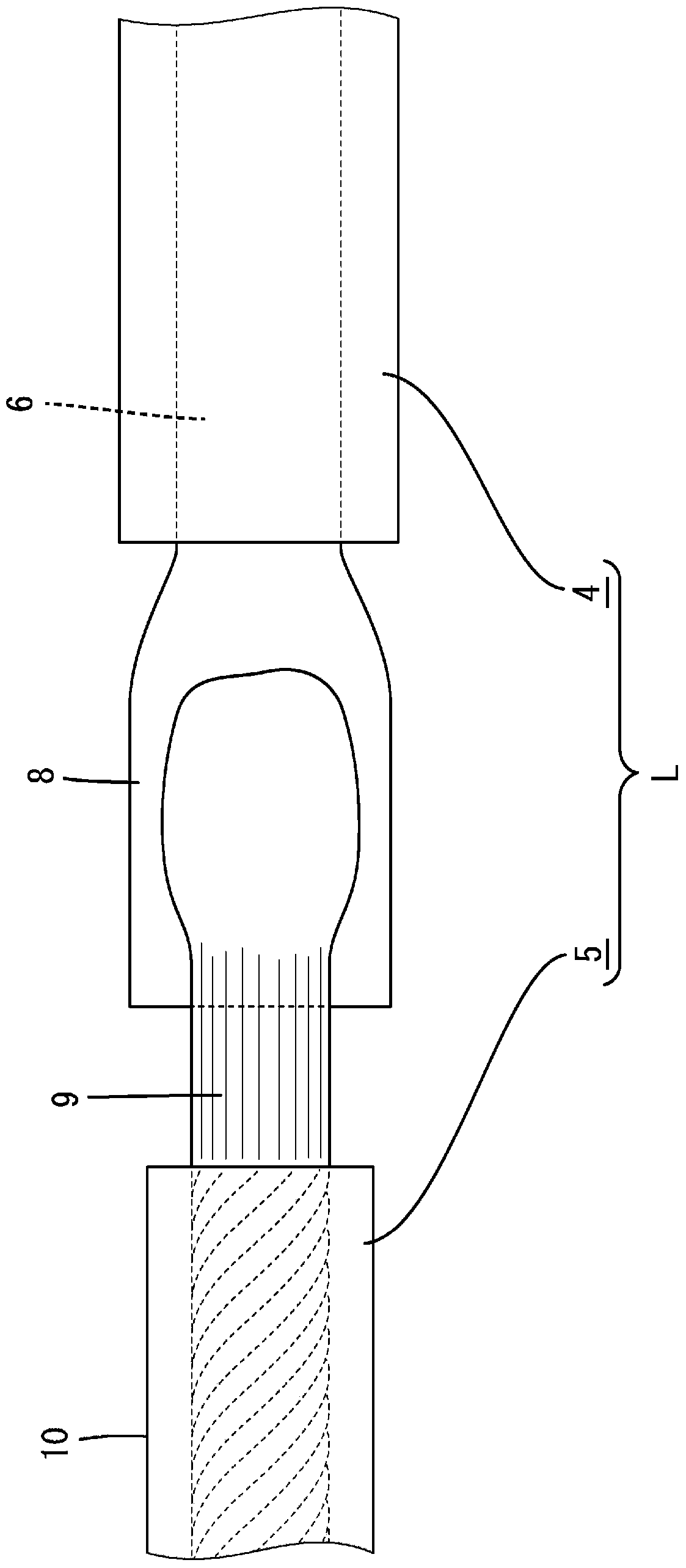

Conductive line and wiring structure thereof

ActiveCN105408963AImprove flexibilityEasy wiringPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsElectrical conductorUltrasonic welding

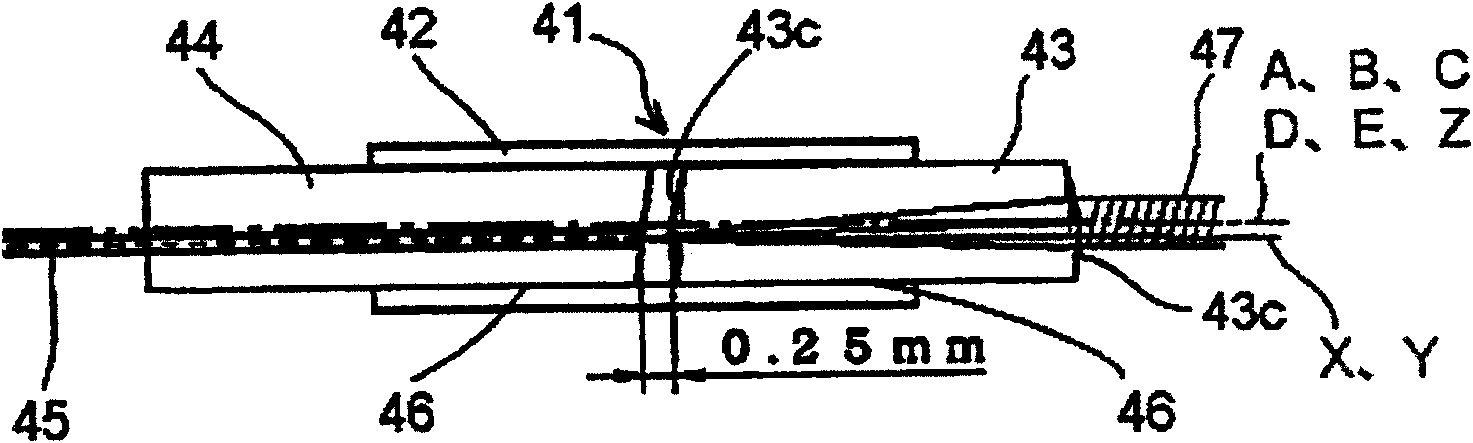

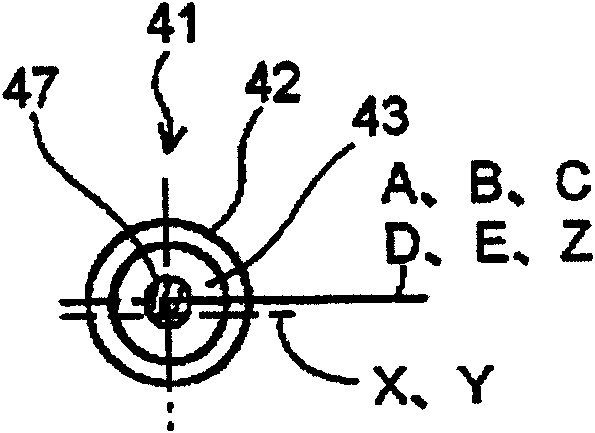

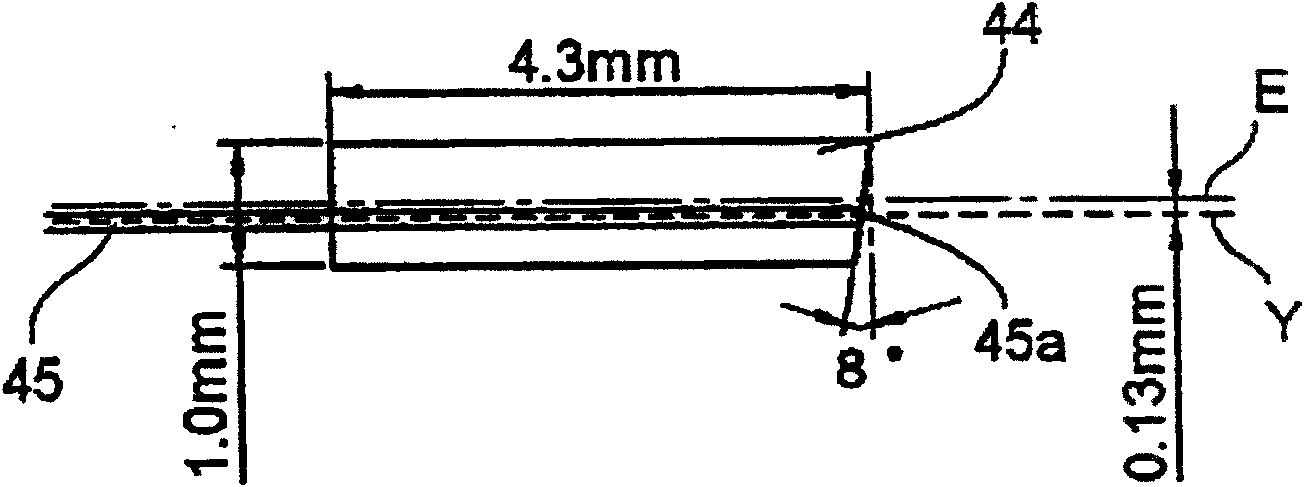

This conductive line (L) comprises a single-core cable (4) formed by encasing a single conductor (6) in a coating (7), and a twisted cable (5) formed by twisting together a plurality of base lines (9) and encasing the base lines (9) in a coating (10), wherein one of the two ends in the direction of length of the single-core cable (4) has the coating (7) peeled away and the conductor (6) is exposed. The exposed conductor (6) has formed therein a pressed portion (8) that has been pressed into a flat shape. The base lines (9) exposed at the end of the twisted cable (5) are joined onto the pressed portion (8) by ultrasonic welding.

Owner:SUMITOMO WIRING SYST LTD

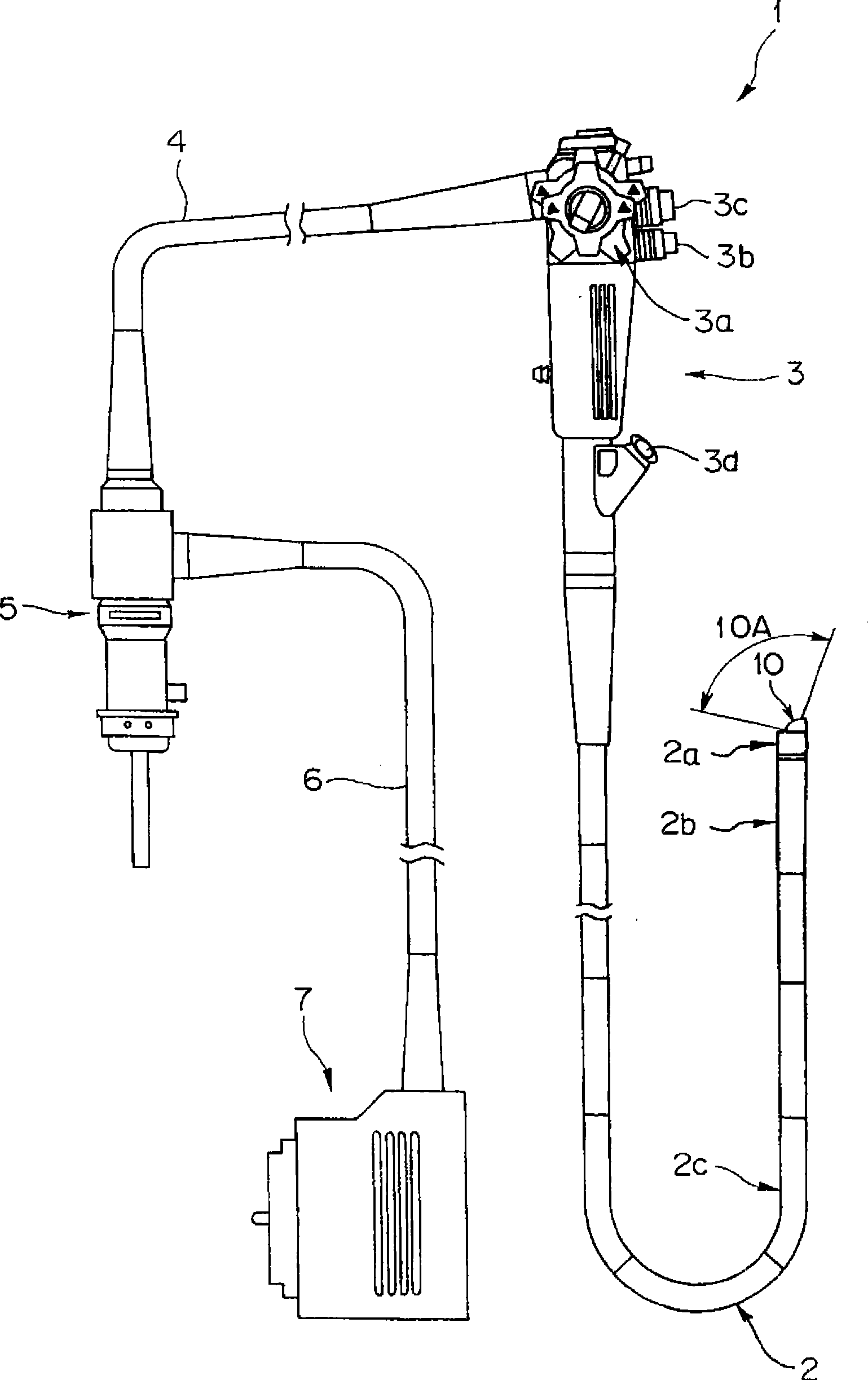

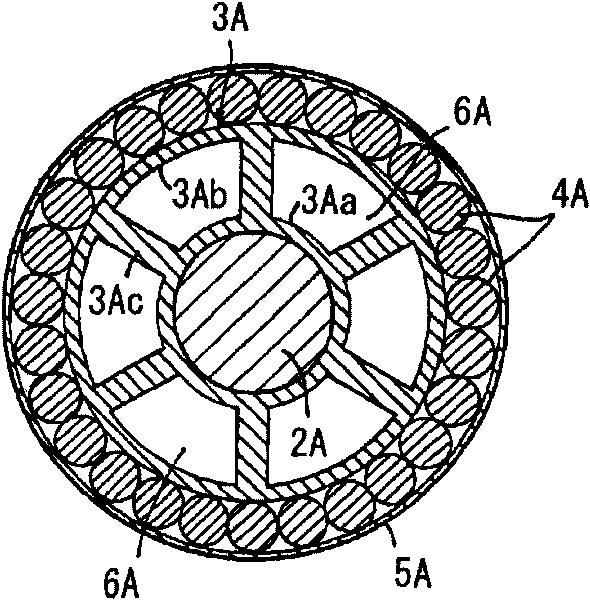

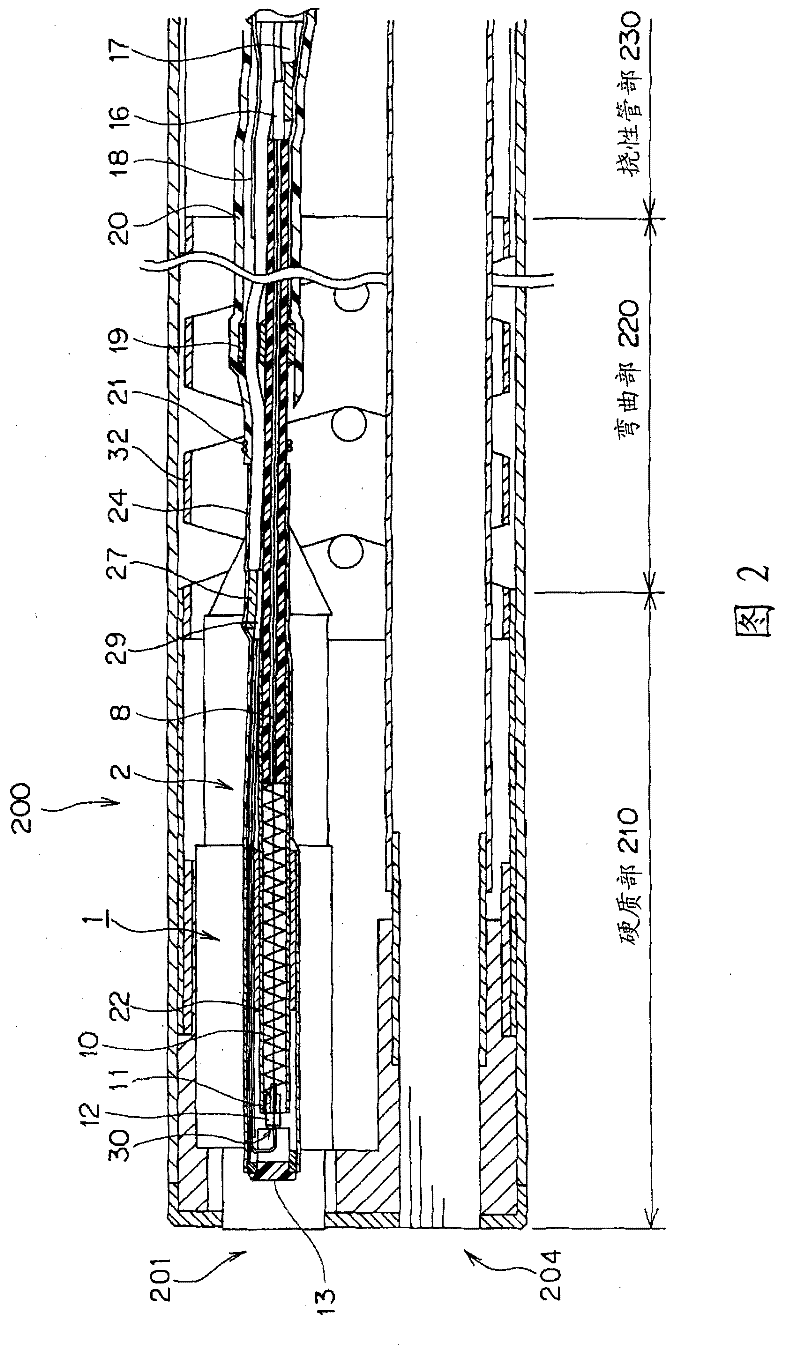

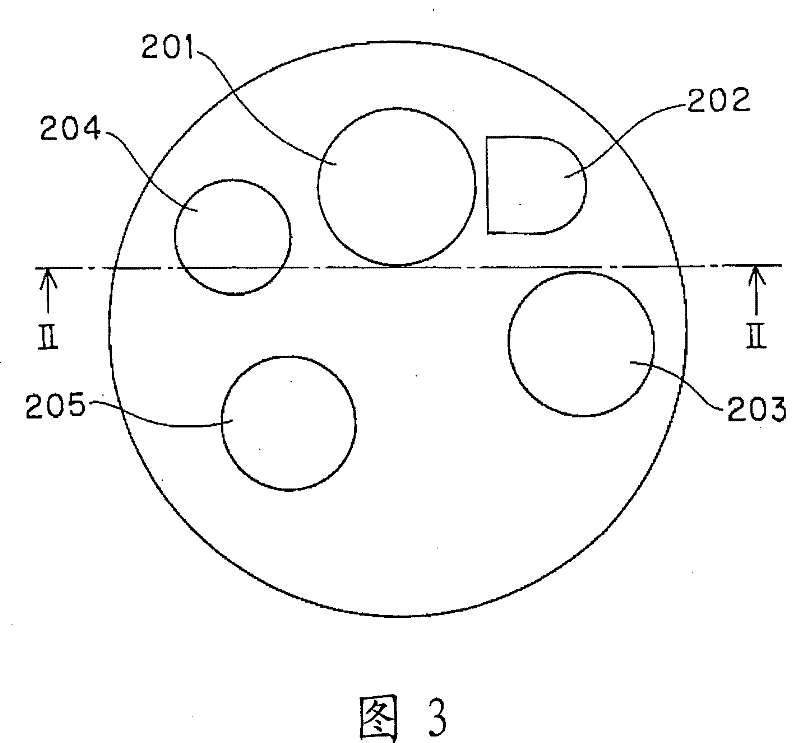

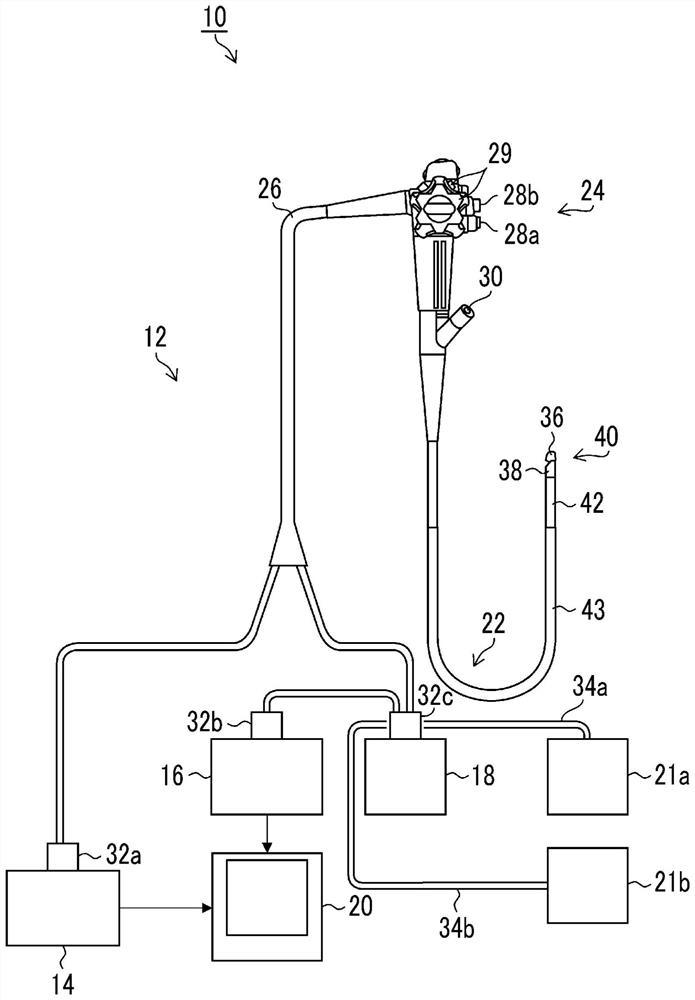

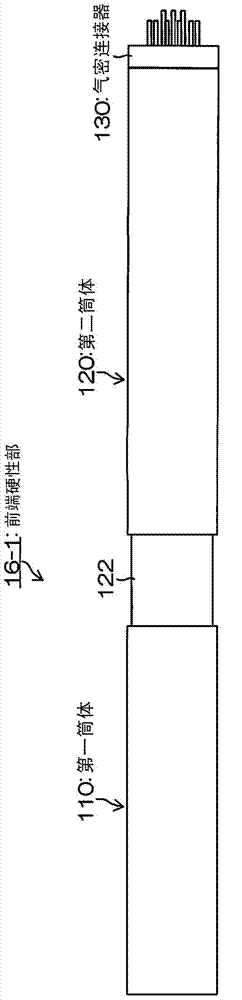

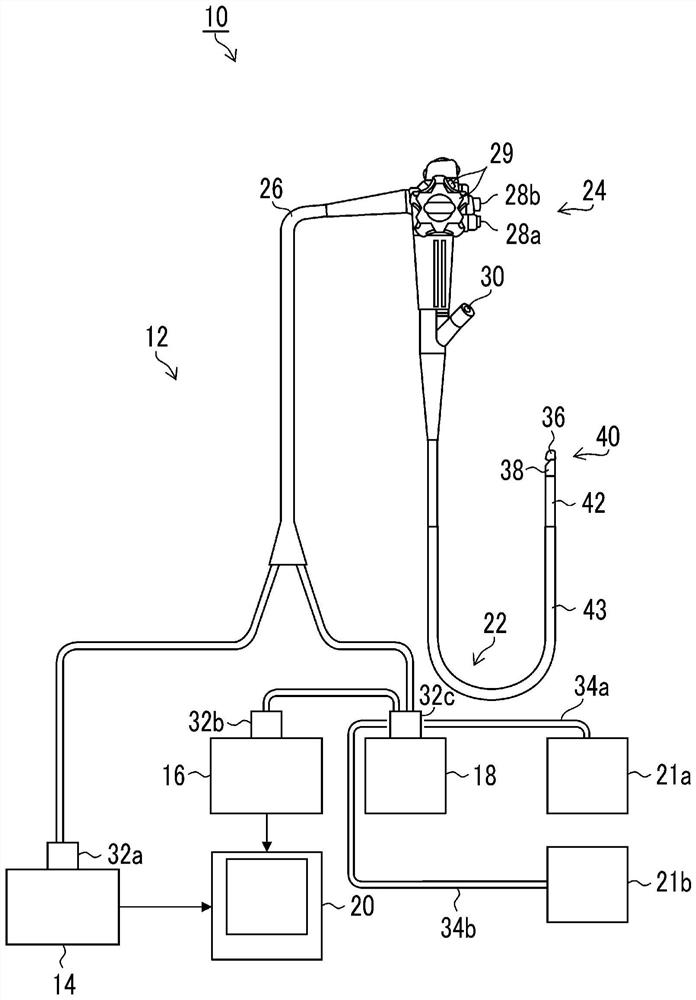

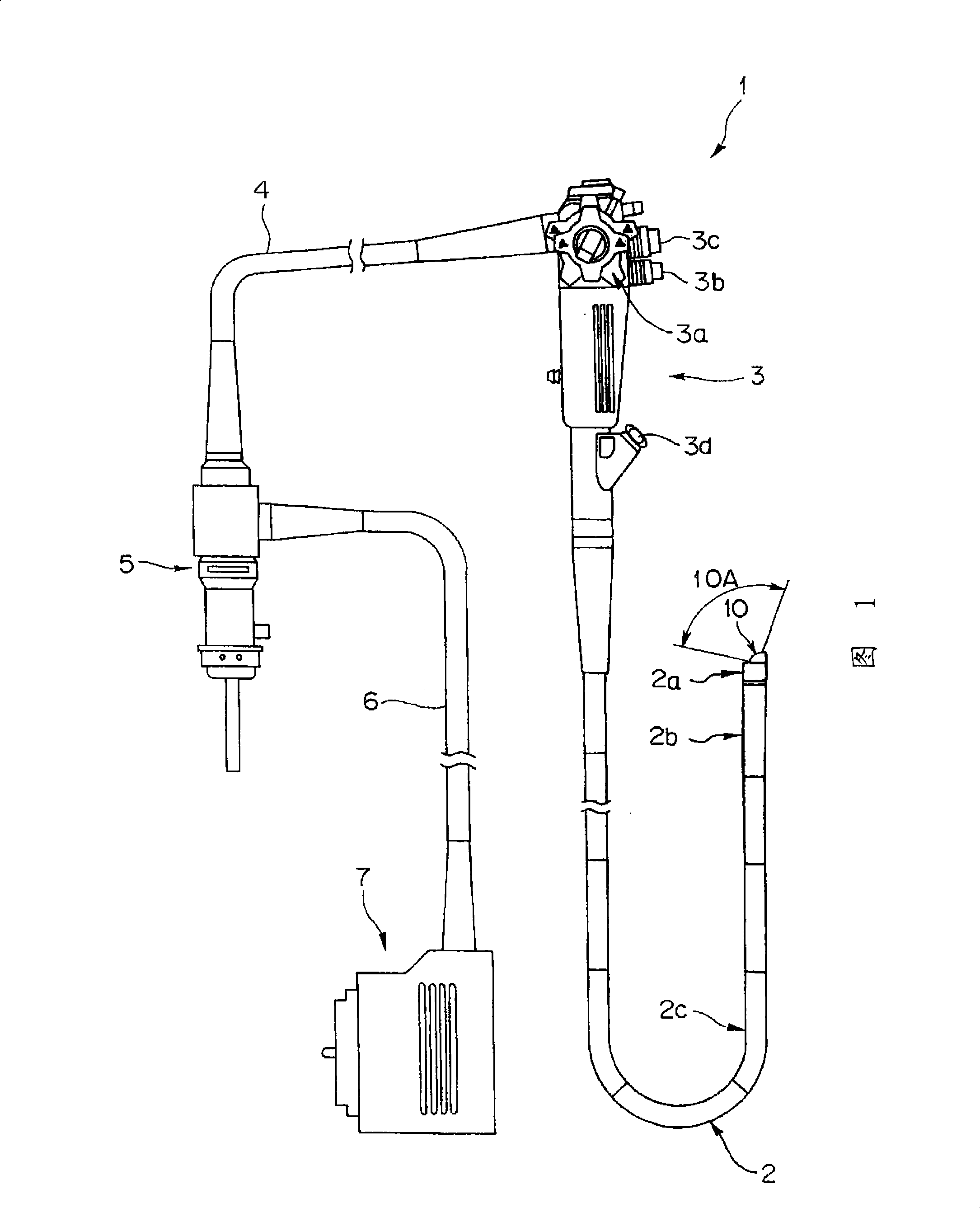

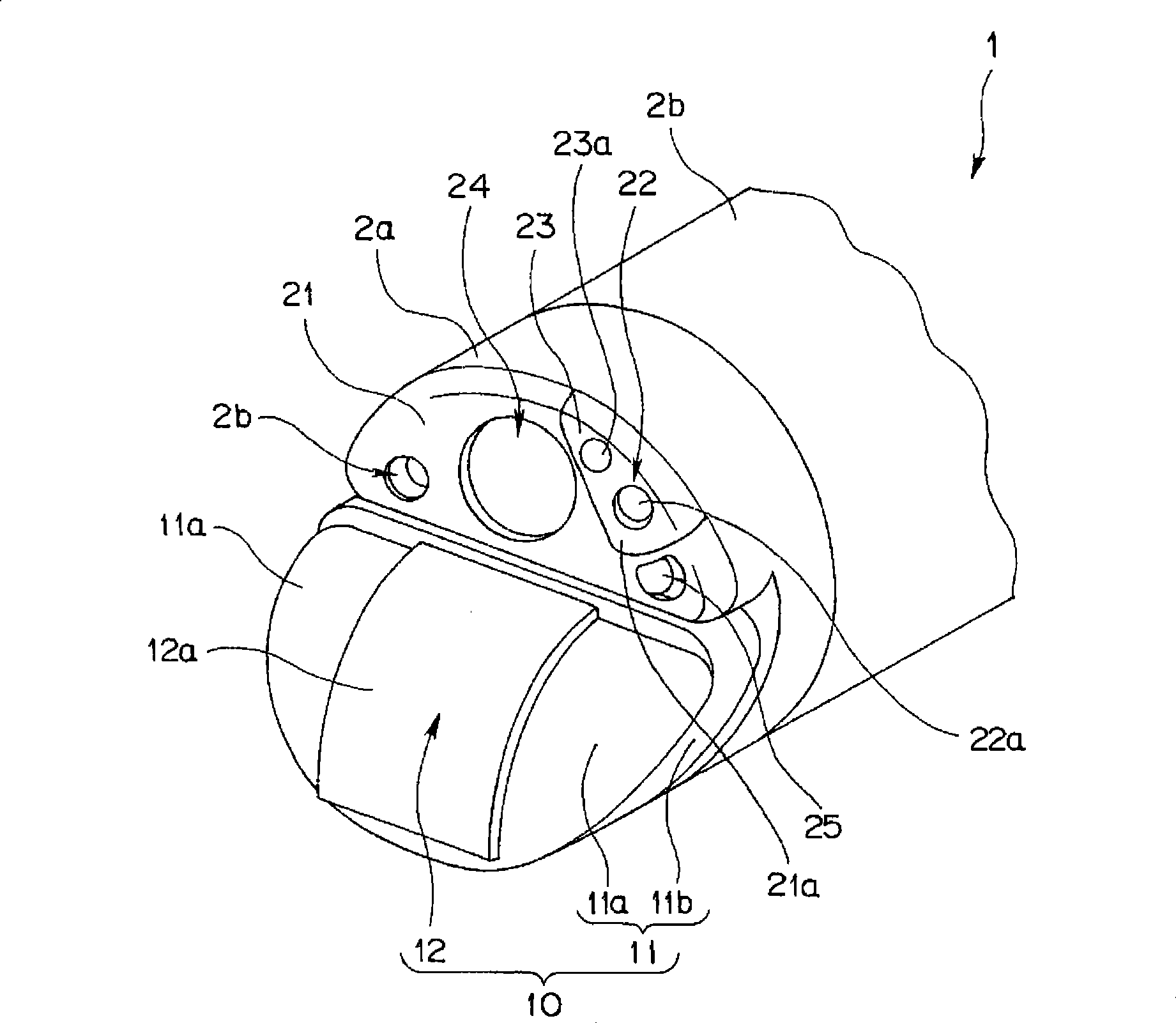

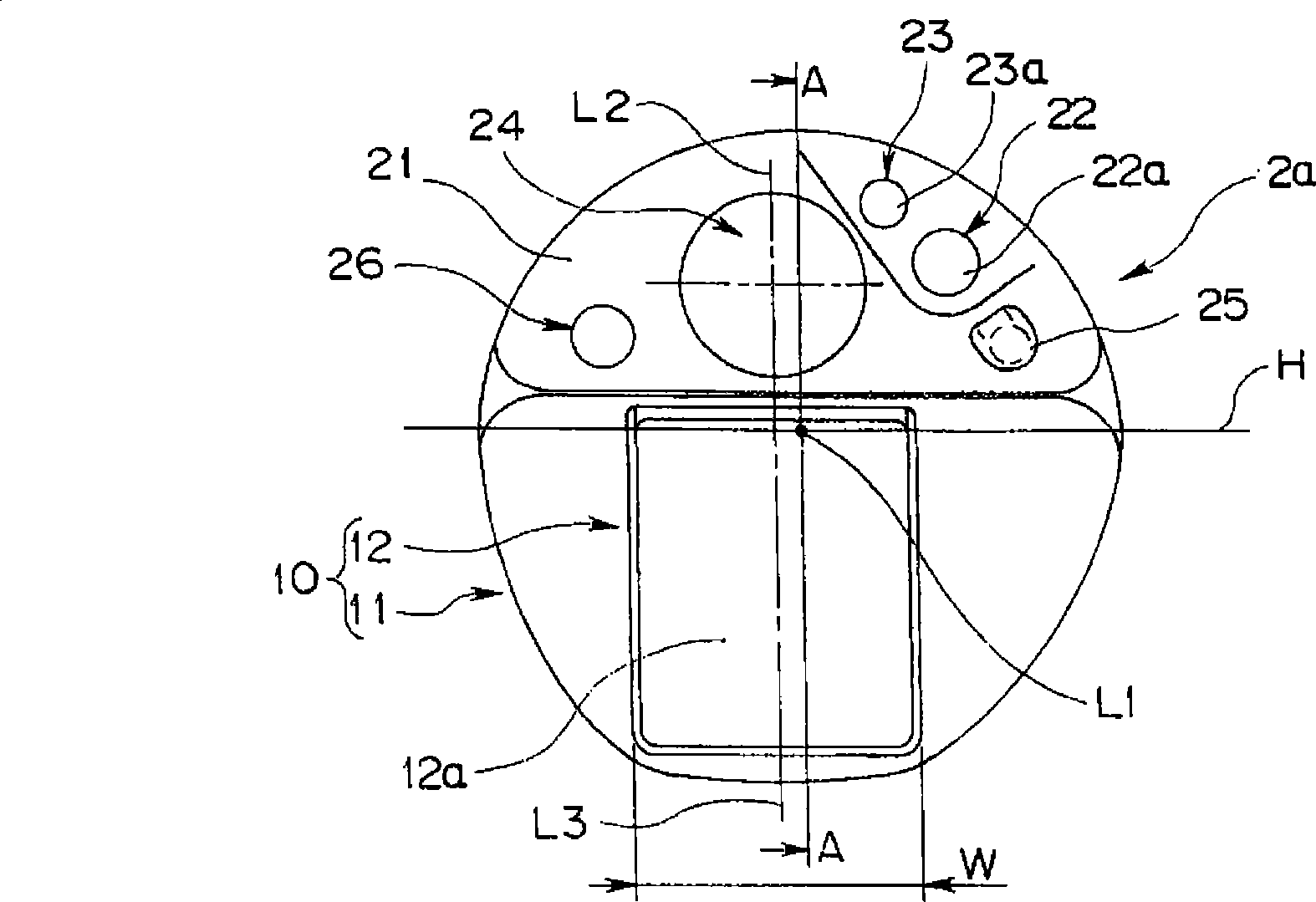

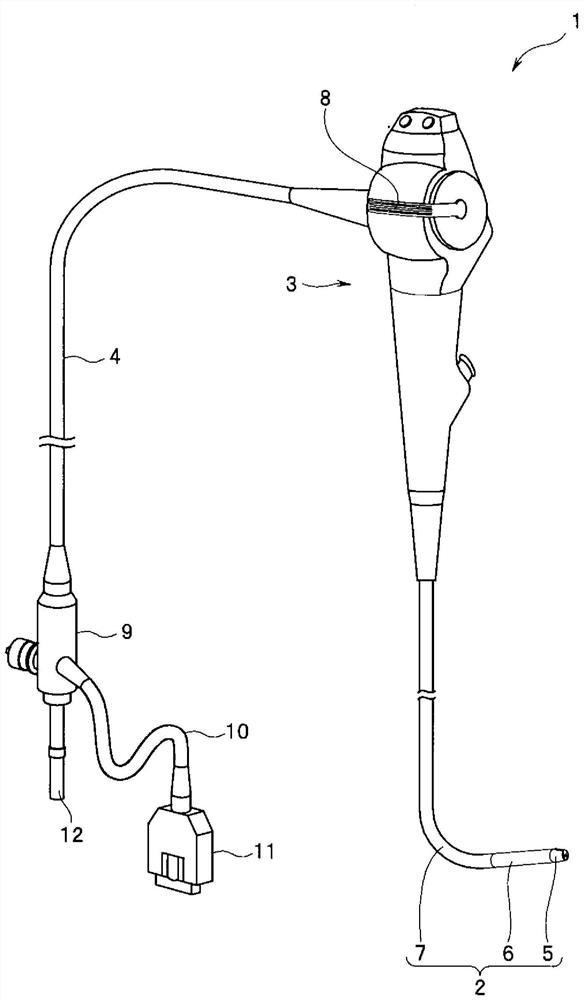

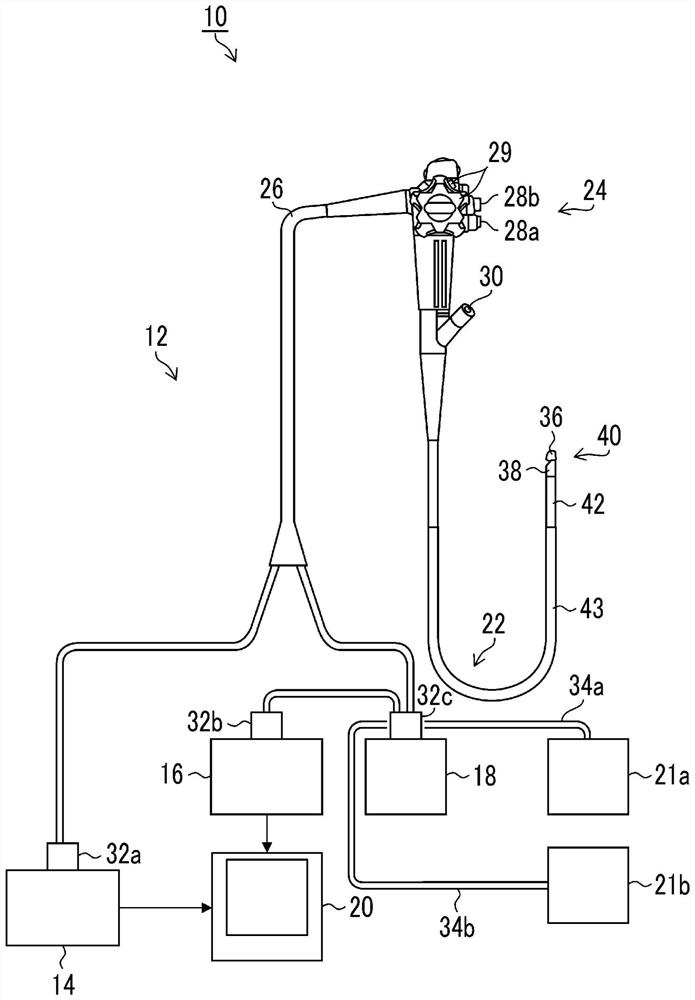

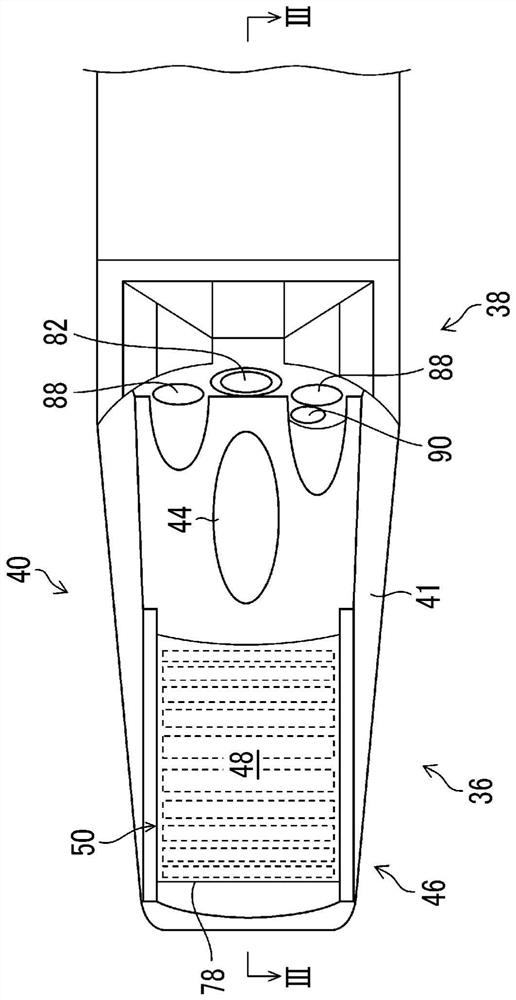

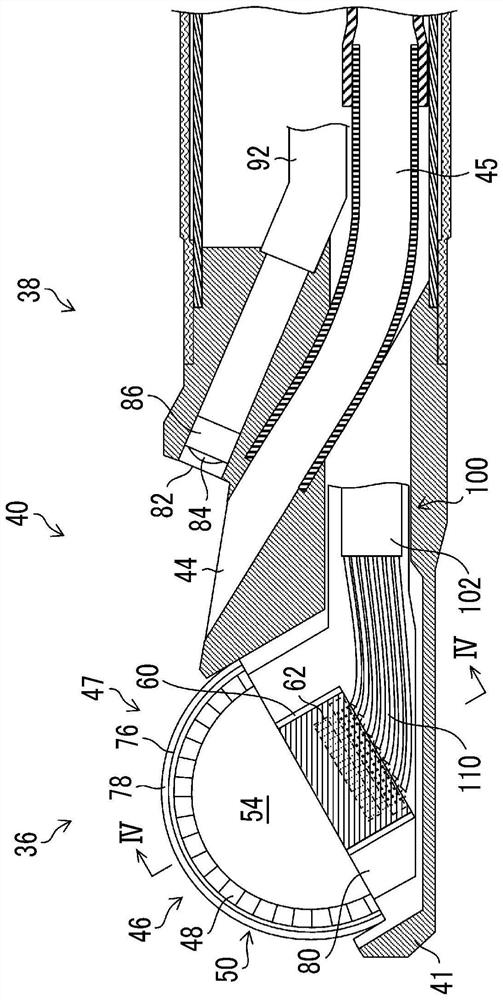

Ultrasonic probe and ultrasonic endoscope with ultrasonic probe

ActiveCN101466314AAchieve finer diameterUltrasonic/sonic/infrasonic diagnosticsPrinted circuit aspectsPrinted circuit boardEngineering

The diameters of an ultrasonic probe and an ultrasonic endoscope are decreased, and electrical connection in respect of a signal line extending from the ultrasonic vibrator is reliably and easily made. The ultrasonic probe comprises vibrator wiring pads (102) provided at the front end of an ultrasonic vibrator printed board (101) where signal patterns for signal transmission / reception of ultrasonic vibrators are formed, flexible printed board wiring pads (108) arranged in line along the longitudinal axis of the ultrasonic vibrator printed board (101), second signal patterns (106) connected between the vibrator wiring pads (102) and the flexible printed board wiring pads (108) and bent generally 90 degrees at intermediate portions, and a relay flexible printed board (121) connected to the flexible printed board wiring pads (108) and used to change the direction of the signal patterns to the longitudinal axis direction.

Owner:OLYMPUS CORP

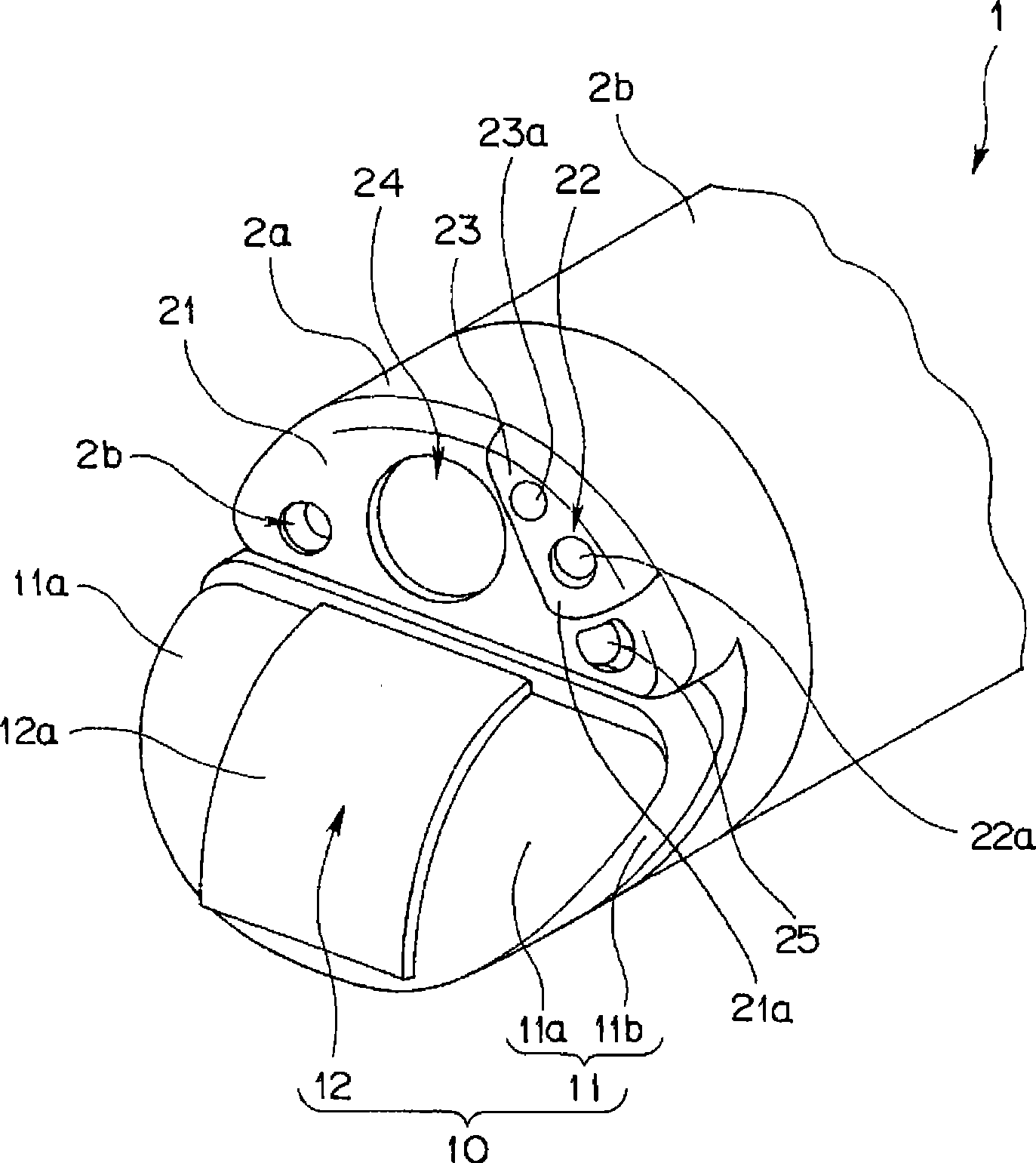

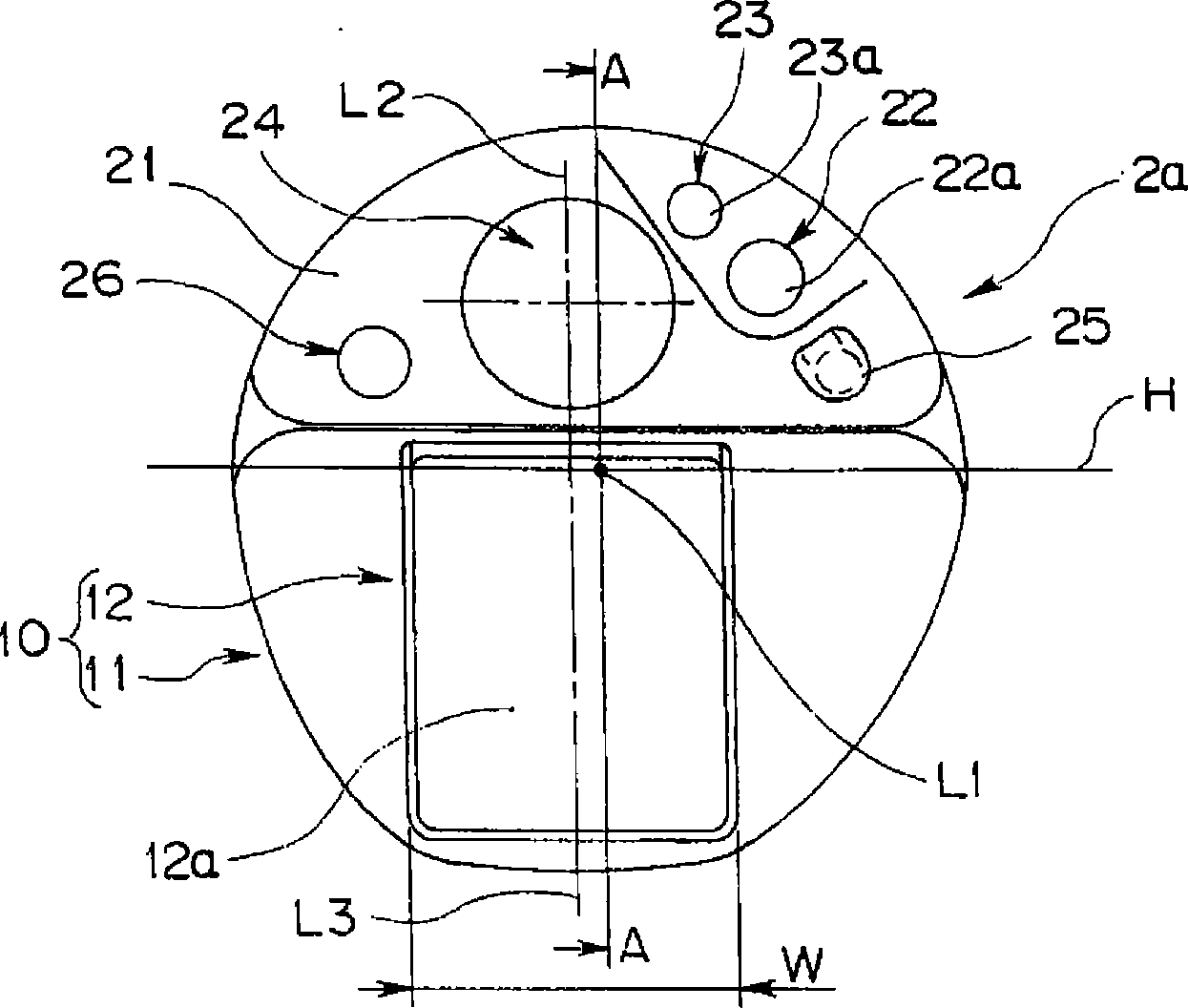

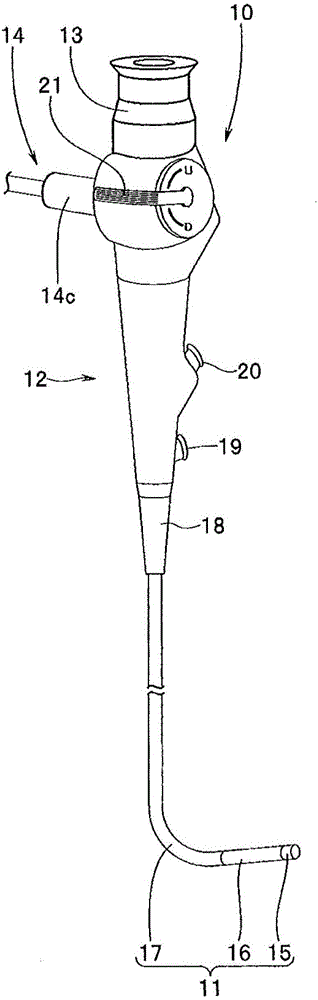

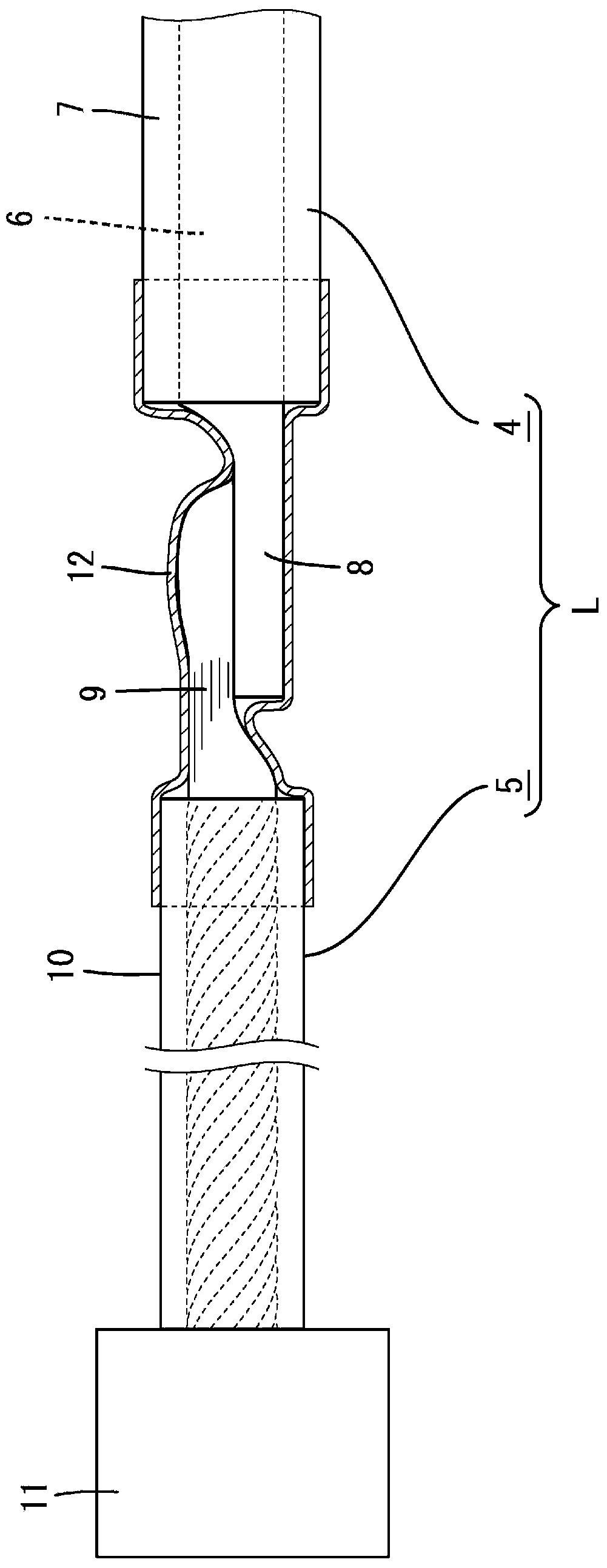

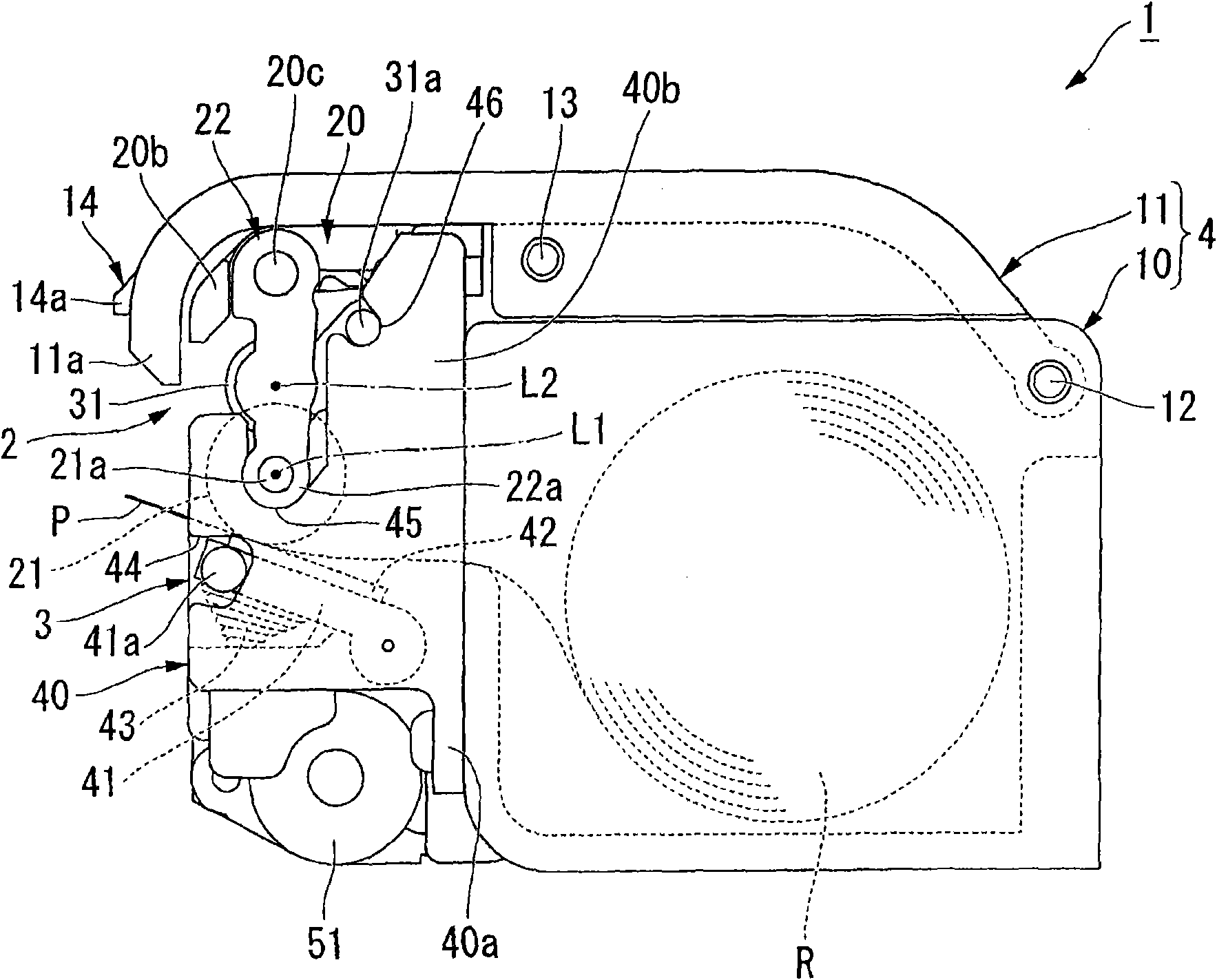

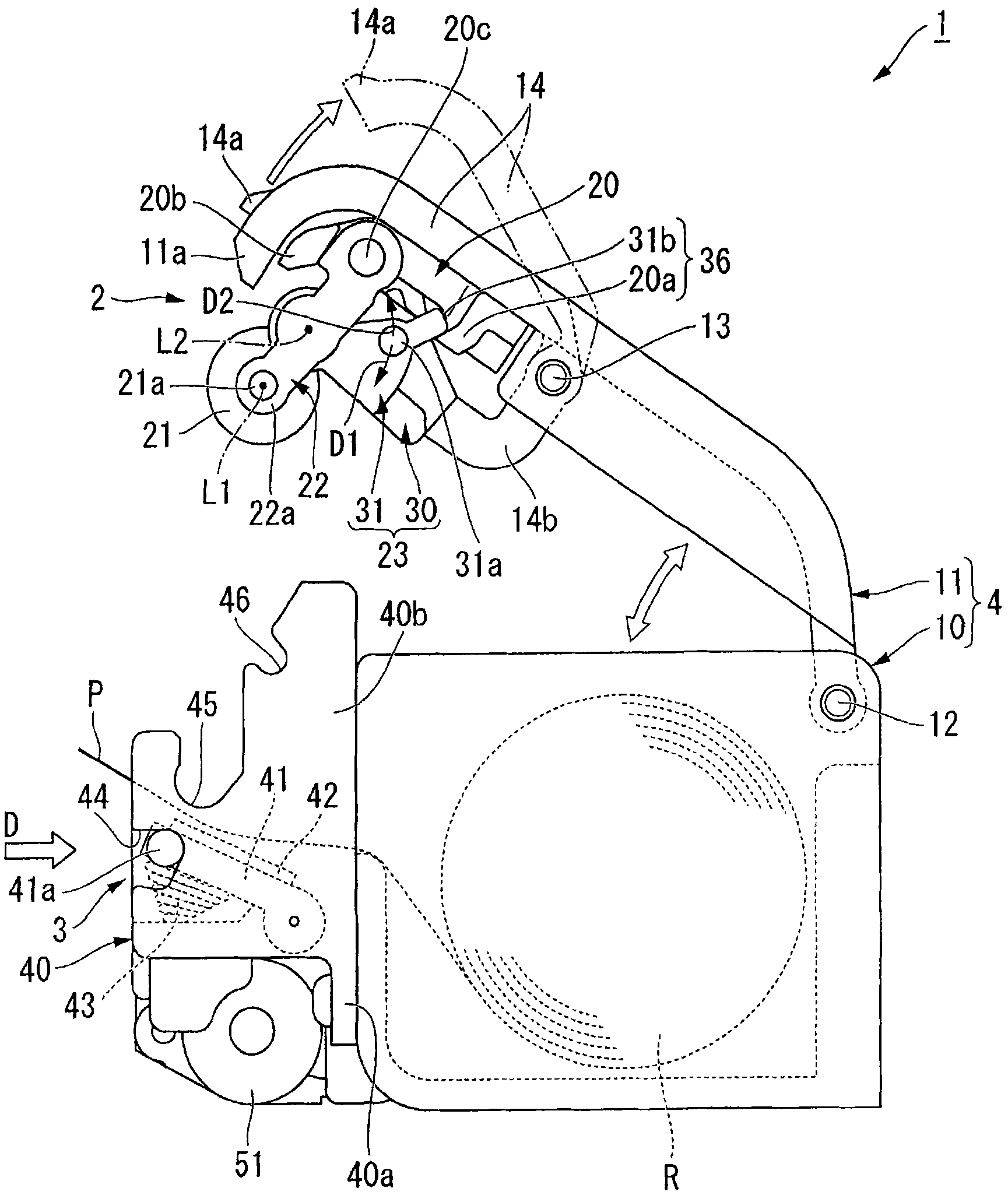

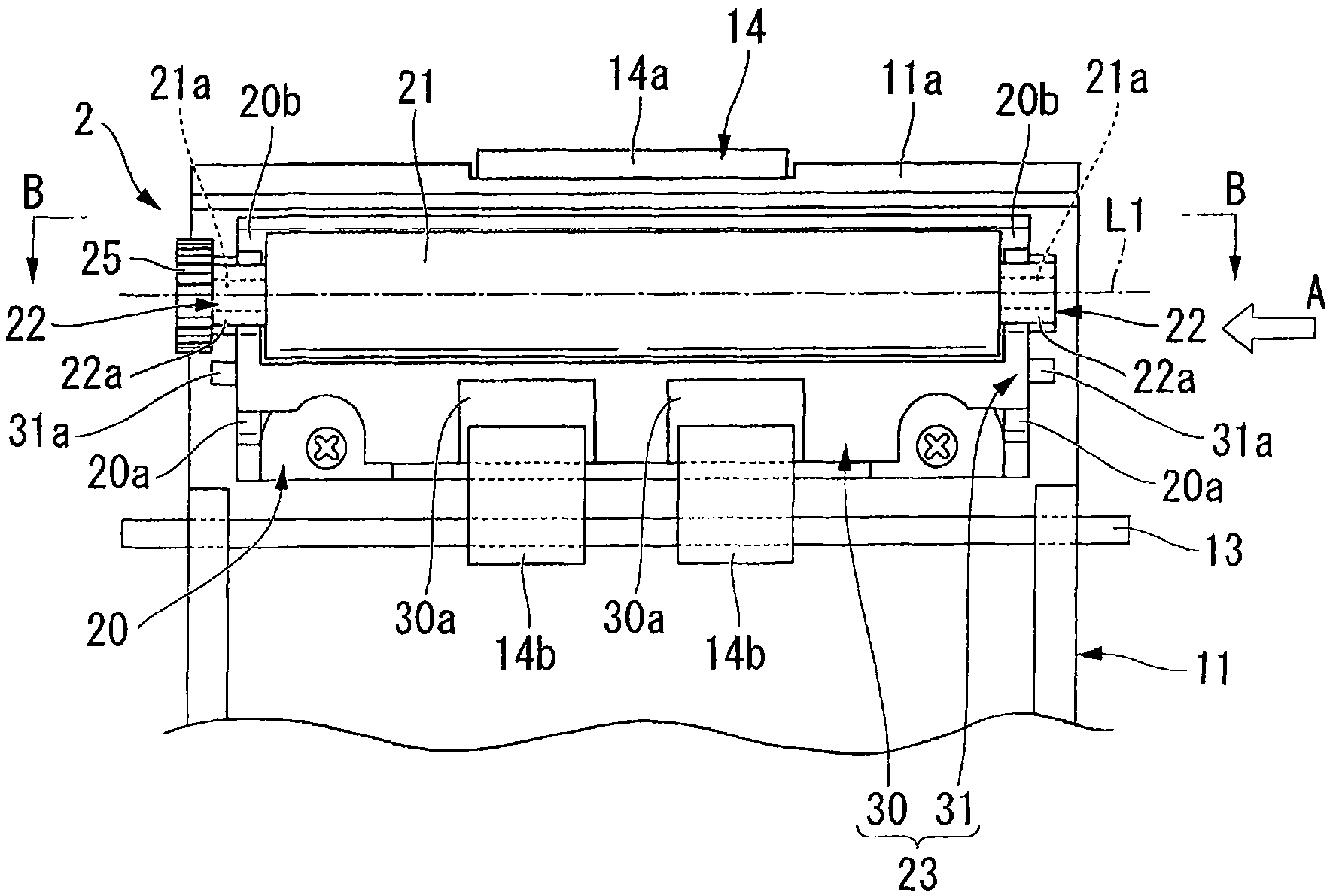

Printer

ActiveCN102189813AEasy loading and unloadingQuick combinationOther printing apparatusEngineeringMechanical engineering

Provided is a printer in which attachment and detachment manipulation of a platen roller can be easily performed, in which the platen roller can be retained with high reliability at a time of attachment, and in which downsizing of the entire printer is achieved due to use of the platen roller smaller in diameter. A printer (1) includes: a rocking member (22) including a bearing portion (22a) for axially supporting a platen roller (21); a latch member (23) coupled to the rocking member so as to be rotatable about a rotary axis (L2) that is non-coaxial with and parallel to a platen axis (L1); a protrusion (31 a) provided to the latch member; and a stationary frame (40) to which a recording head (42) is fixed, in which: the stationary frame includes a first recess (45) into which the bearing portion is disengageably fitted, the first recess retaining the platen roller at a position of facing the recording head, and a second recess (46) into which, after the bearing portion is fitted, the protrusion is disengageably fitted; and the bearing portion is undisengageable from inside the first recess while the protrusion is fitted, and is disengageable from inside the first recess after the protrusion is disengaged.

Owner:SEIKO INSTR INC

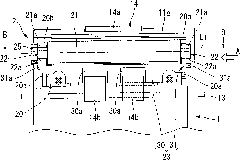

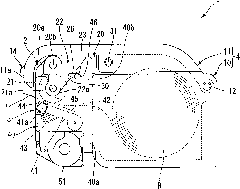

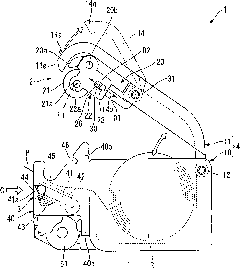

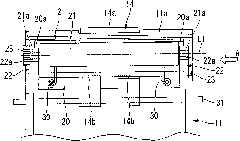

Printer

ActiveCN102189814AEasy loading and unloadingImprove reliabilityTypewritersOther printing apparatusIn planeEngineering

Provided is a printer in which attachment and detachment manipulation of a platen roller can easily be performed, in which the platen roller can be retained with high reliability at a time of attachment, and in which downsizing of the entire printer is achieved due to use of the platen roller smaller in diameter. A printer (1) includes: a rocking plate (22) including a bearing portion (22a) for axially supporting a platen roller (21); a rock shaft (23) inserted through a slide opening portion (26) so as to be combined with the rocking plate; and a stationary frame (40) to which a recording head (42) is fixed, in which: the rock shaft is slidingly movable in an imaginary in-plane direction orthogonal to a platen axis; the stationary frame includes a first recess (45) into which the bearing portion is disengageably fitted, and a second recess (46) into which, after the bearing portion is fitted, the rock shaft is disengageably fitted; and the bearing portion is undisengageable from inside the first recess while the rock shaft is fitted, and is disengageable from inside the first recess after the rock shaft is disengaged.

Owner:SEIKO INSTR INC

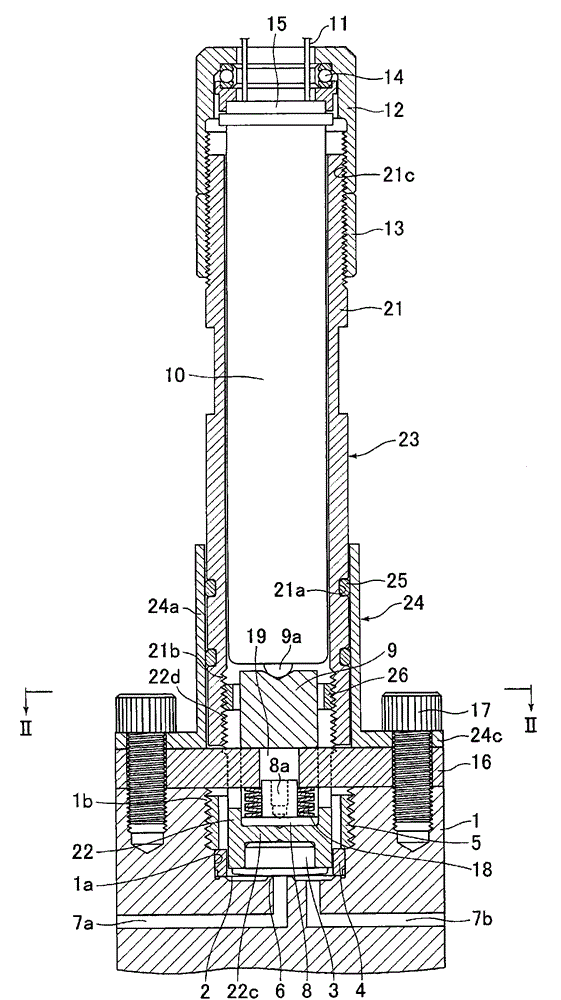

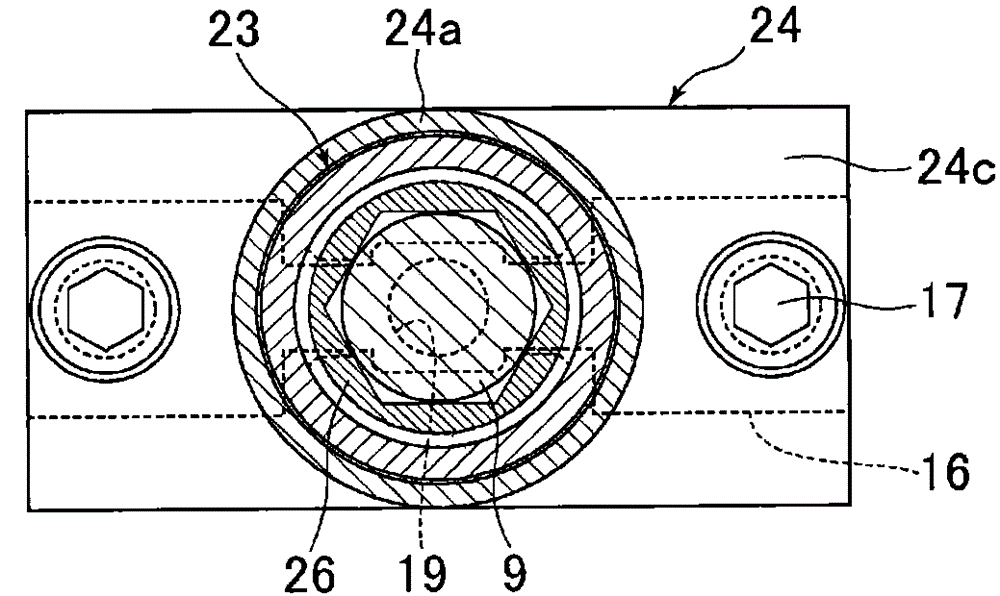

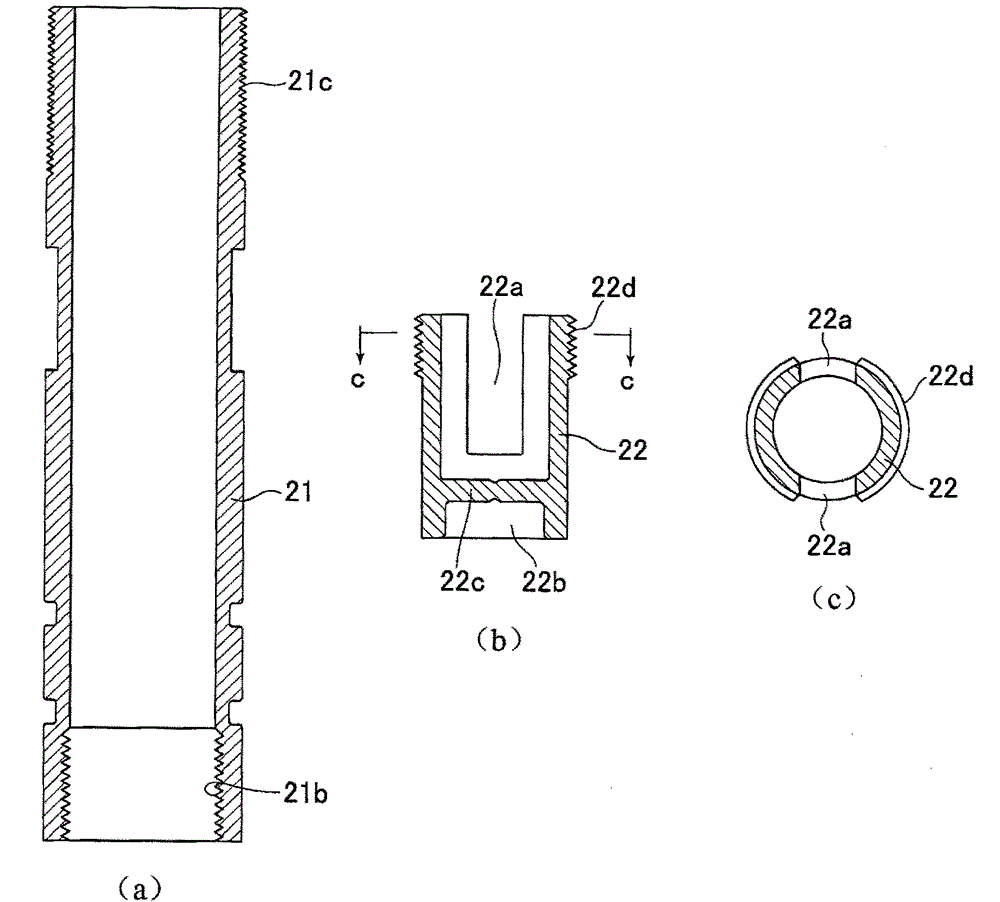

Flow rate control valve for flow rate control device

InactiveCN105190142AImprove simplicityImprove assembly accuracyDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveControl valves

By being designed to simplify and reduce the size of the structure of a piezoelectric element-driven metal diaphragm control valve to be used in flow rate control devices, etc. and to simplify assembly and maintenance thereof, the present invention makes it possible to respond to the demand for more types of supply gases and supply circuits without causing increases in the size of integrated gas supply units for semiconductor-manufacturing devices, etc. The present invention is obtained from: a main valve body (1), which is equipped with a valve chamber hole (1a) that is open at the upper end and has a valve seat (6), and a fluid inlet path (7a) and a fluid outlet path (7b) communicating with same; an inverted dish-shaped metal diaphragm valve body (2), which is disposed above the valve seat (6) facing same and the outer circumferential edge of which is fixed to the bottom surface of the valve chamber hole (1a); a pressing screw (5), which is screwed into the valve chamber hole (1a) to press and fix the outer circumferential edge of the metal diaphragm valve body (2); a lower support cylinder (22), which passes through the inside of the pressing screw (5) and is inserted into the valve chamber hole (1a), is provided with a diaphragm press (3) below the bottom wall of the tip, and is provided with rectangular notches (22a) extending from the upper end to the middle of the side walls so as to pass through the side walls; a cylindrical upper support cylinder (21), which is screwed onto the upper end of the lower support cylinder (22) to form a support cylinder (23); a disc spring cradle (8) loaded on the bottom wall of the lower support cylinder (22) and having a holder section (8a); a disc spring (18) loaded on the disc spring cradle (8); a support frame (16), which is inserted in the notches (22a) of the lower support cylinder (22) and disposed horizontally, which has, at the center, a disc spring cradle guiding hole (19) for holding the tip of the disc spring holder section (8a), and which is provided with bolt insertion holes (20) at both ends; a lower cradle (9) loaded above the disc spring cradle guiding hole (19) of the support frame (16); a piezoelectric element (10) inserted inside the support cylinder (23) above the lower cradle (9); a guide (24), which is provided with a guide tube (24a) and flanges (24c) protruding from the lower end thereof to both sides, which is for inserting the support cylinder (23) inside the guide tube (24a) so as to allow vertical movement, and the flanges (24c) of which are made to face the two ends of the support frame (16) and are fixed to the main valve body (1) together with the support frame (16) using fixing bolts (17); and a positioning nut (12) screwed onto the upper end of the upper support cylinder (21). The support cylinder (23) is pushed upward by the expansion of the piezoelectric element (10) and the metal diaphragm valve body (2) is separated from the valve seat (6) by the elastic force of the metal diaphragm valve body.

Owner:FUJIKIN INC

Probe pin

InactiveCN101743481AIncreased pull-out strengthIncreased buckling strengthTwo pole connectionsElectrical measurement instrument detailsElectrical conductorBiomedical engineering

Owner:MITSUBISHI CABLE IND LTD

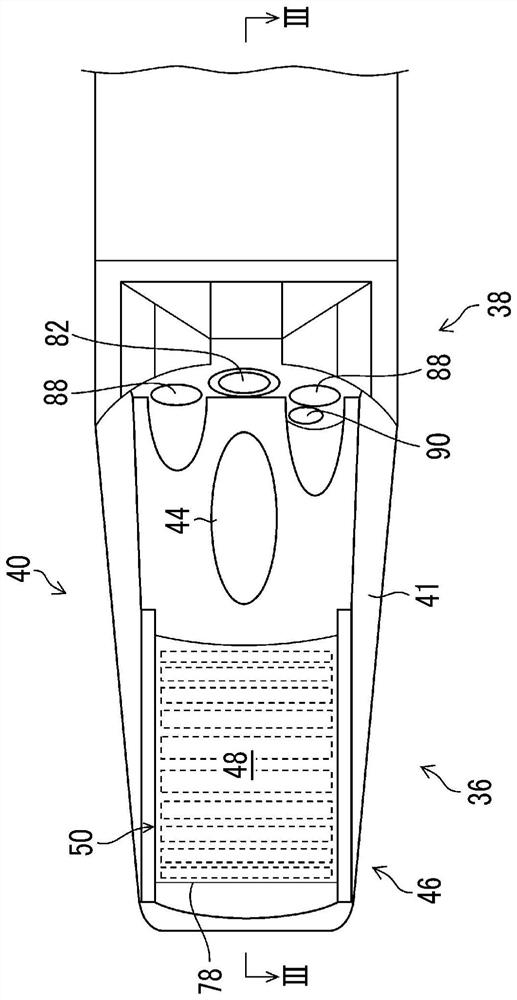

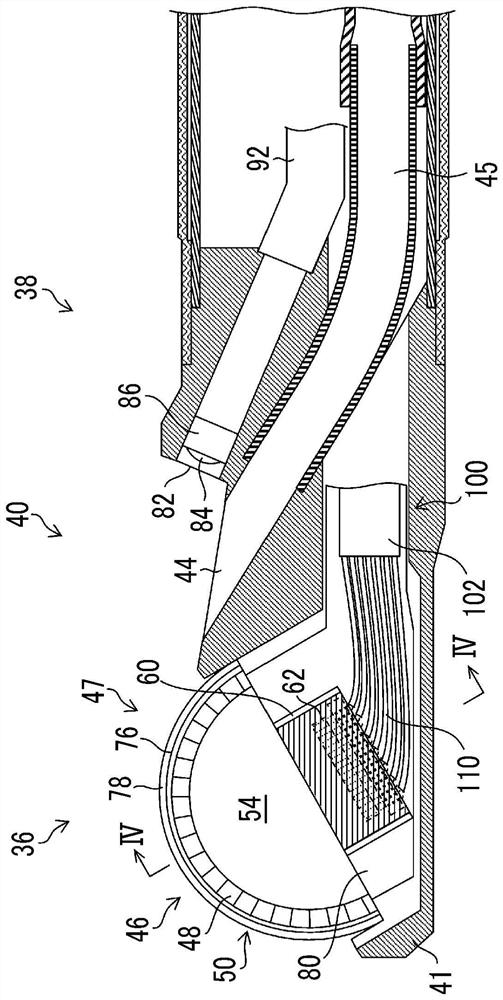

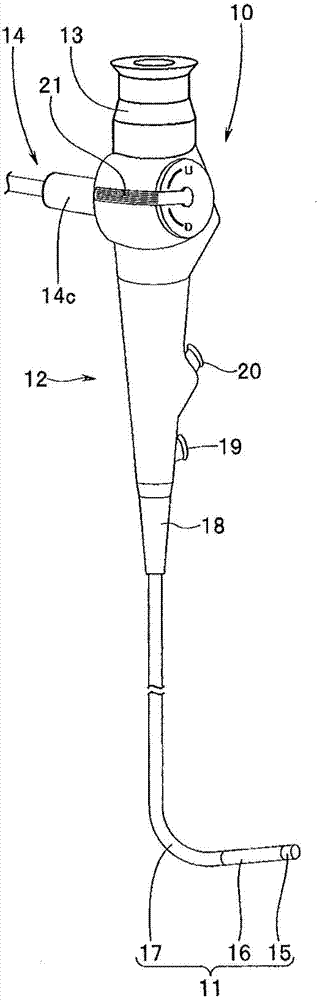

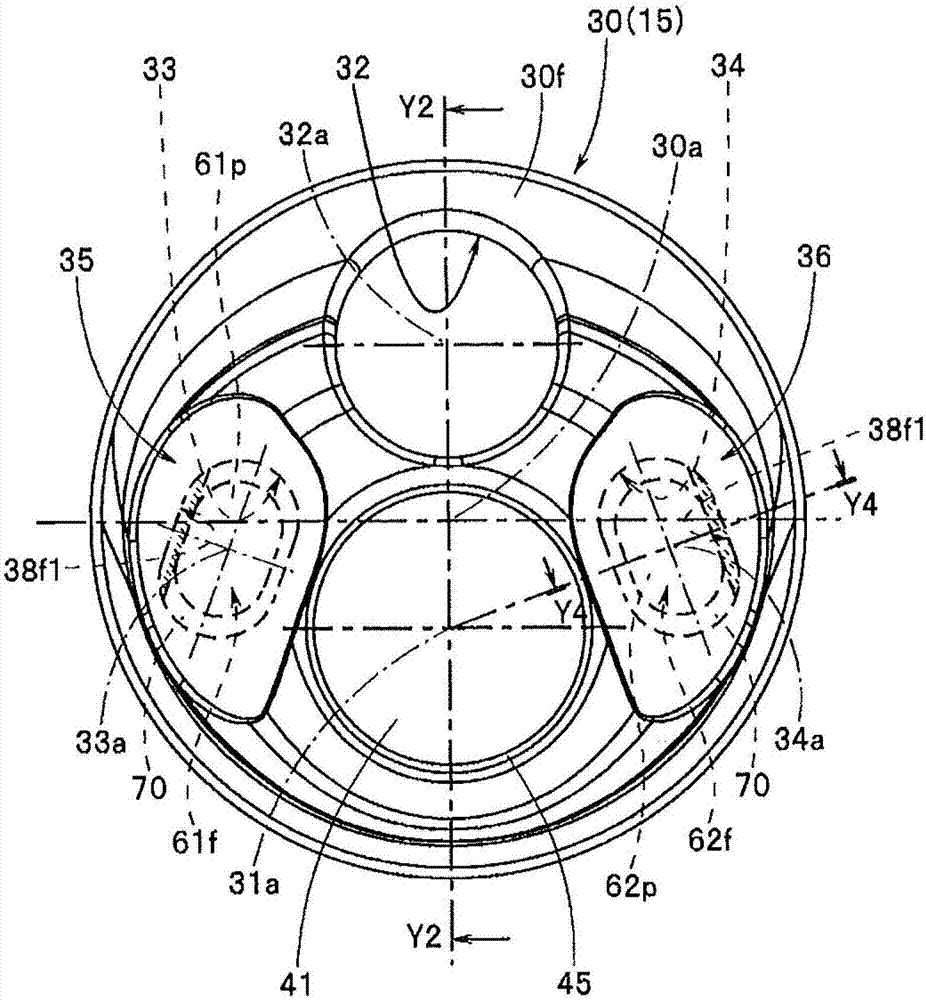

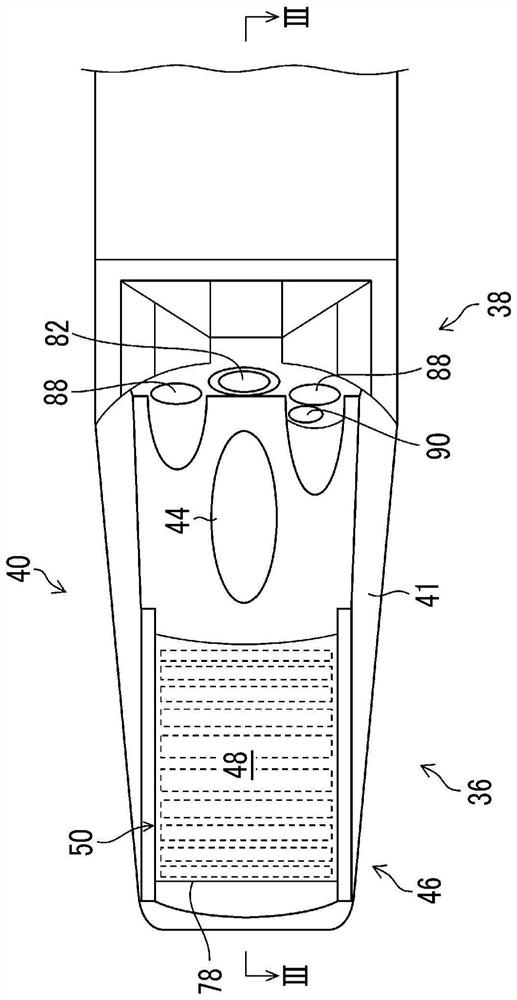

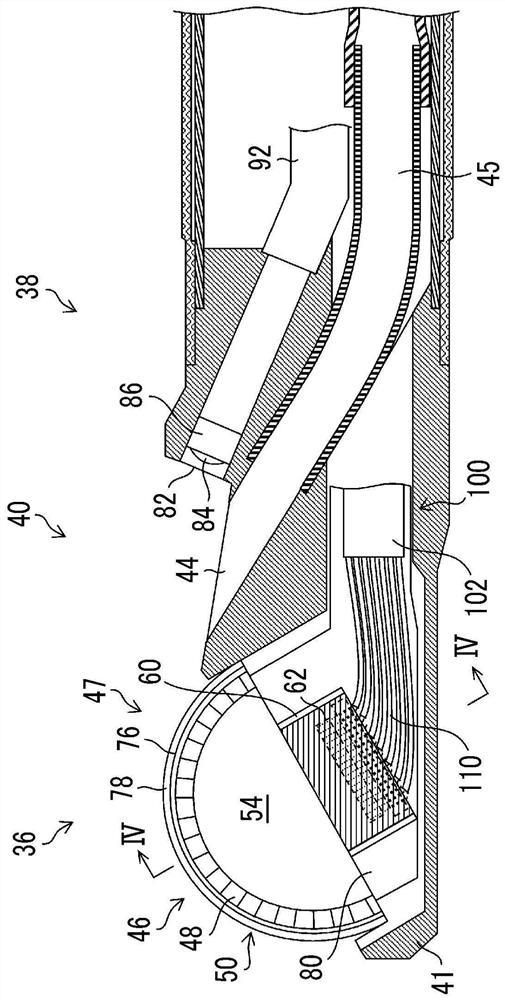

Endoscope

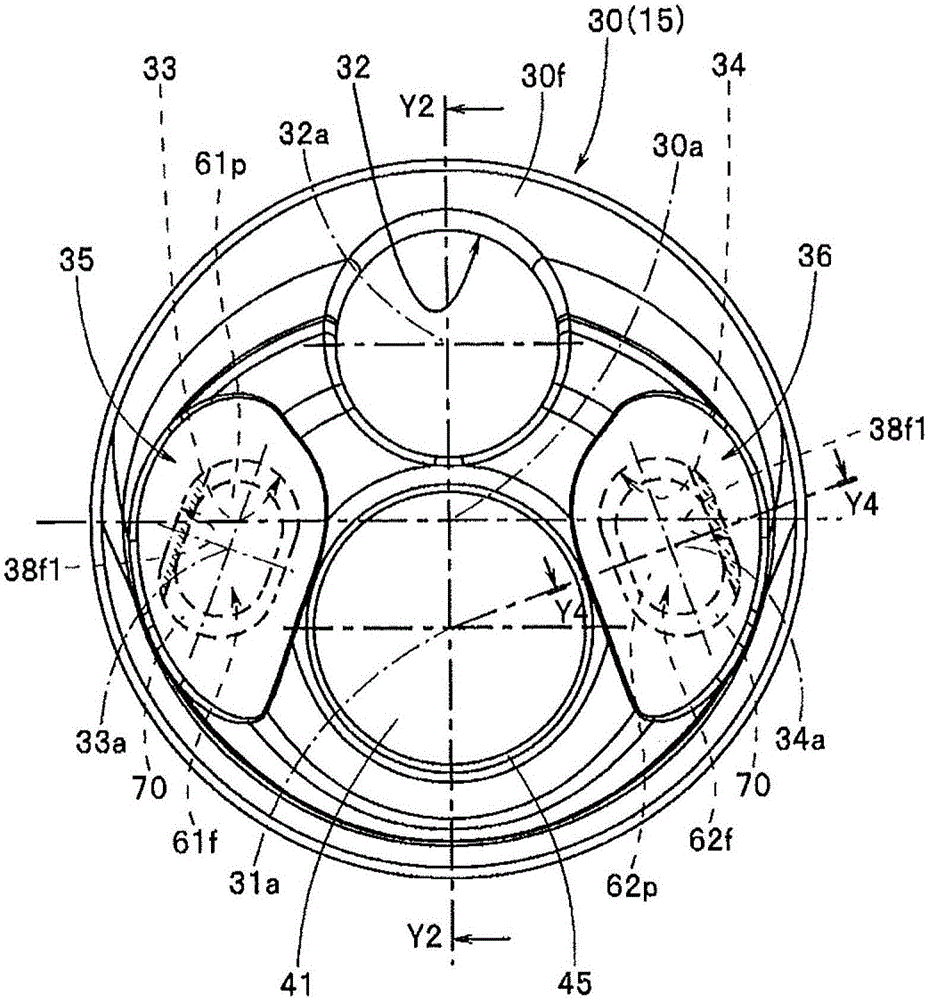

ActiveCN106231978AAchieving Desired Optical PerformanceAchieve finer diameterSurgeryEndoscopesFiberLight guide

This endoscope 10 comprises: a first fiber 61 of a light guide fiber 60, the first fiber 61 having a tip part on which a first flat surface 61f for emitting illumination light is provided, the first flat surface 61f being formed inclined at an angle of less than 90 degrees with respect to a longitudinal axis 61a; a pipe 70 which has a through hole 71 to which a tip portion 61p of the first fiber 61 is secured and which has a tip surface 73 that includes a first surface 73a capable of being flush with the first flat surface 61f and a second surface 73b which is a flat surface orthogonal to the central axis 71a of the through hole 71; and a tip component 30 which has a blind hole 34 into which a tip end of the pipe 70 is disposed, wherein the bottom side of the blind hole 34 is provided with an abutting surface 38f2 to which at least a part of the second surface 73b of the pipe 70 abuts and a recess 37 which is positioned further to the tip side than the abutting surface 38f2 and forms a portion of an illuminating lens system for obtaining a predetermined light distribution.

Owner:OLYMPUS CORP

Medical fabric

ActiveCN108472122AThe overall thickness is thinHas tear strengthStentsFilament/thread formingBiomedical engineeringSingle filament

Provided is a medical fabric that is thin, and has both high tear strength and low water permeability. The medical fabric is characterized in that multifilament yarns having a total fineness of 7-80 dtex are disposed in the warp and weft, the single yarn fineness of at least one of the multifilament yarns among the warp and weft is 0.5 dtex or less, the twist factor A of the weft is 50-2,000, thethickness is 10-90 [mu]m, and the water permeability both before and after puncture by a needle is 300 cc / min / cm2 or less.

Owner:ASAHI KASEI KK

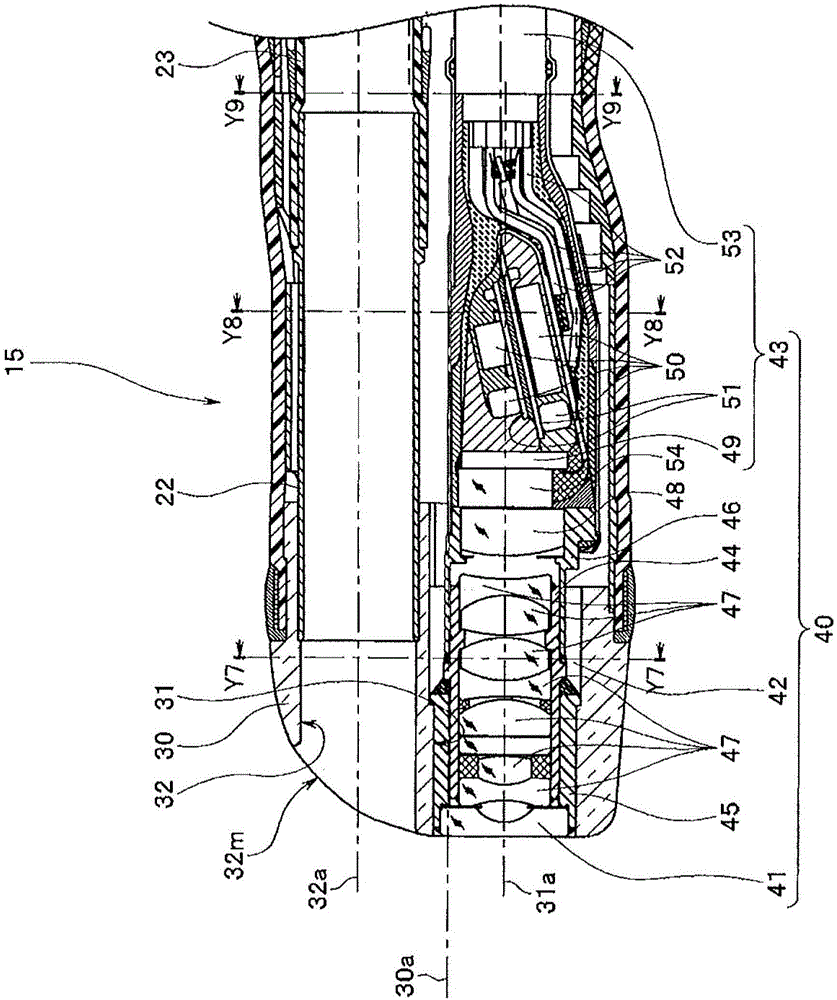

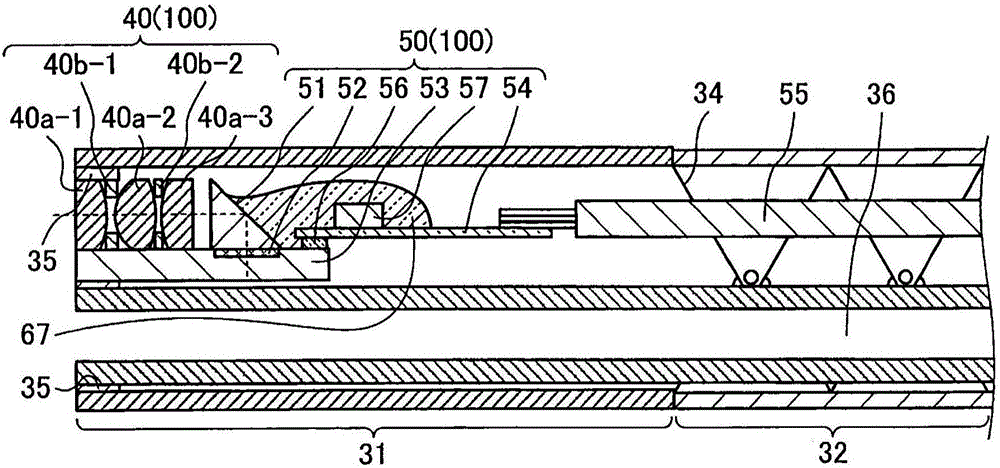

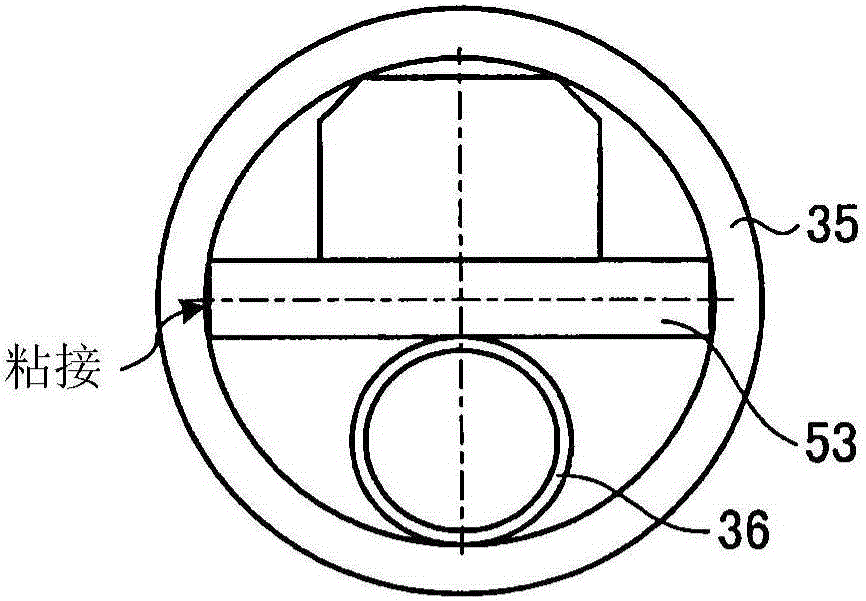

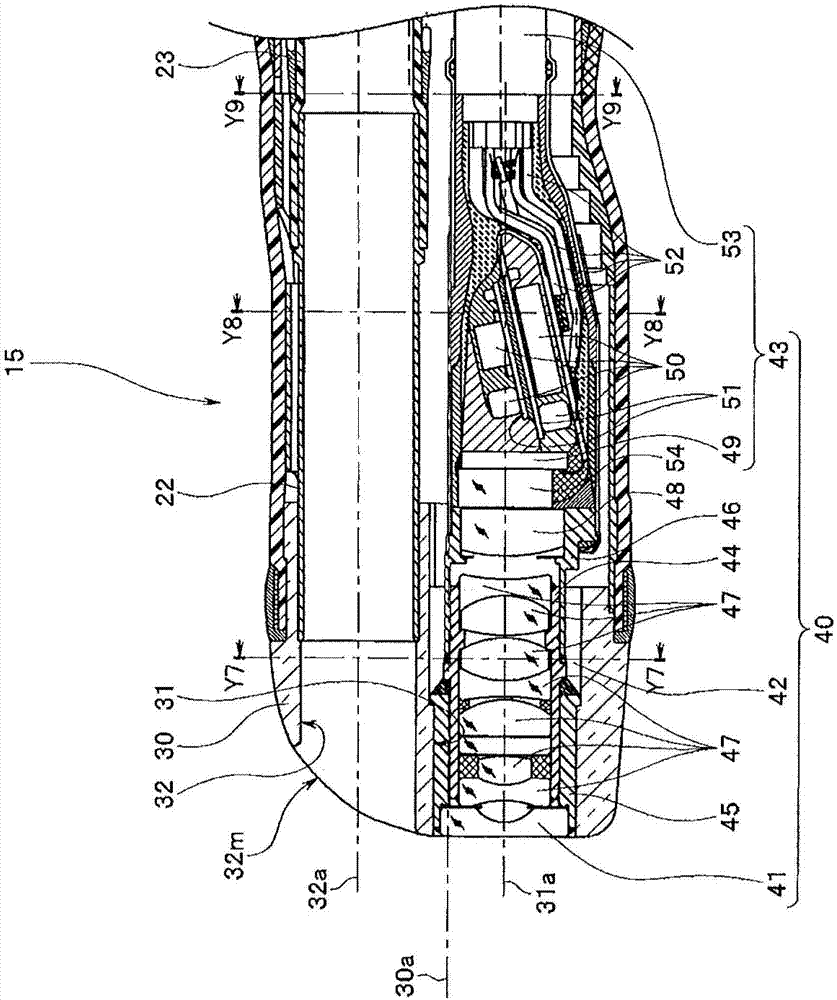

Imaging device and endoscope device

Provided are a miniaturizable imaging device and an endoscope device. The imaging device (100) is characterized by being provided with: objective lenses (40a-1 to 40a-3) that gather incoming light; a prism (51) that reflects the light gathered by the objective lenses (40a-1 to 40a-3); and an imaging element (53) having a light reception unit (52) that generates an electric signal by receiving the light reflected by the prism (51) and performing photoelectric conversion. The imaging device (100) is further characterized in that the prism (51) is mounted above the light reception unit (52), and the objective lenses (40a-1 to 40a-3) are directly mounted to the surface of the imaging element (53).

Owner:OLYMPUS CORP

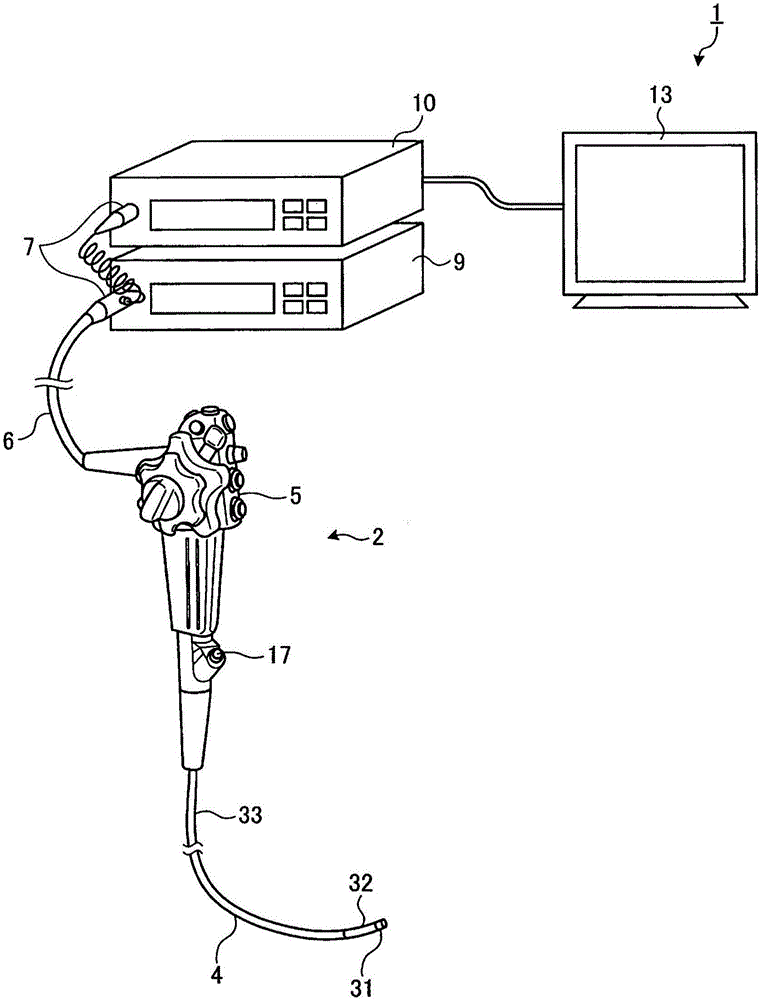

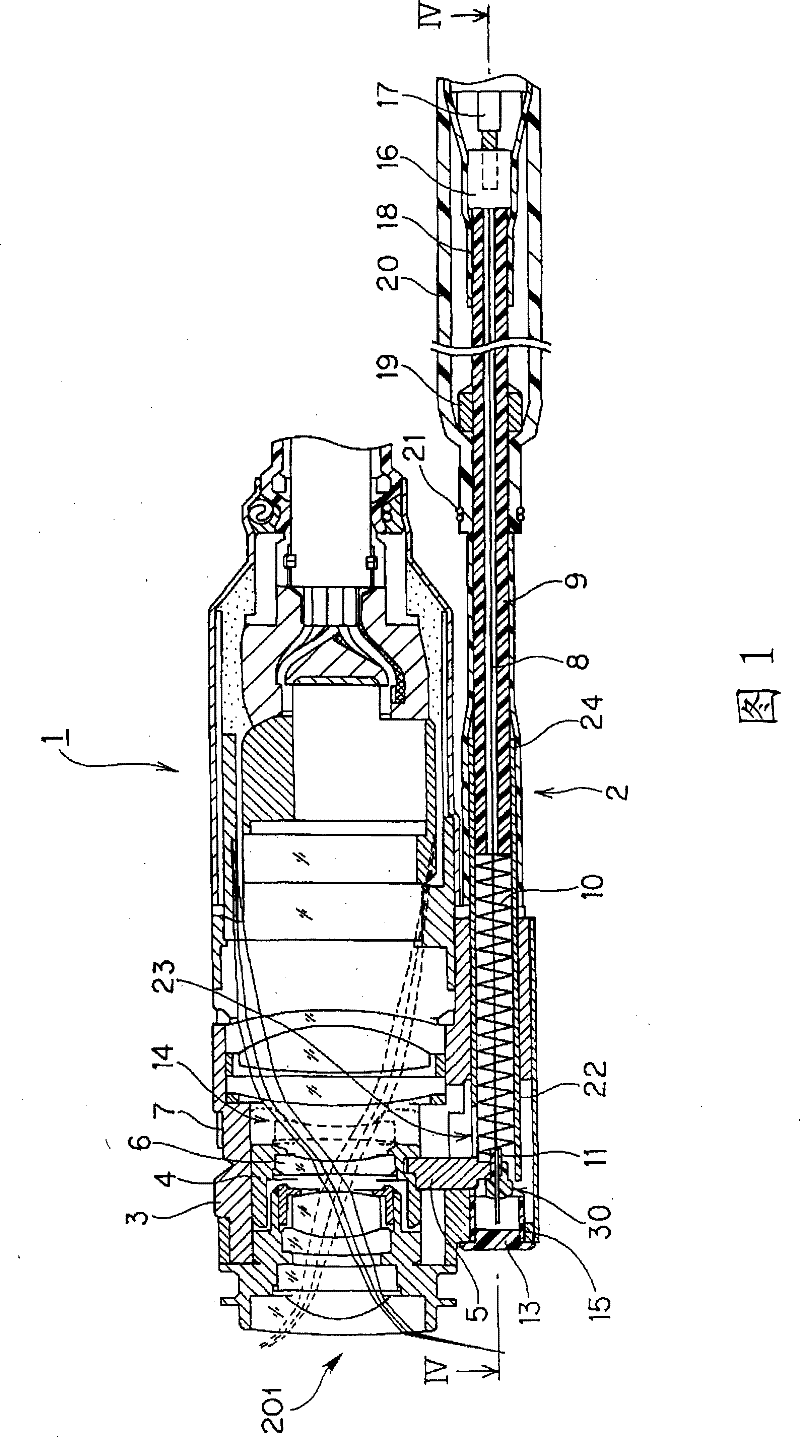

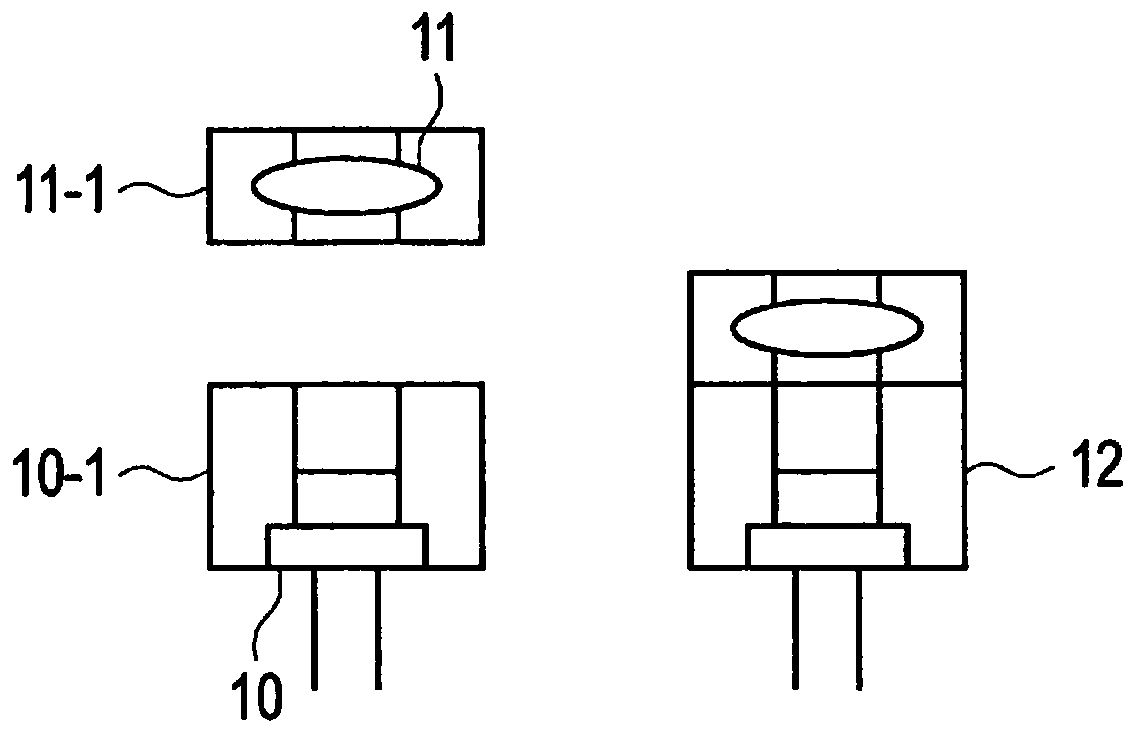

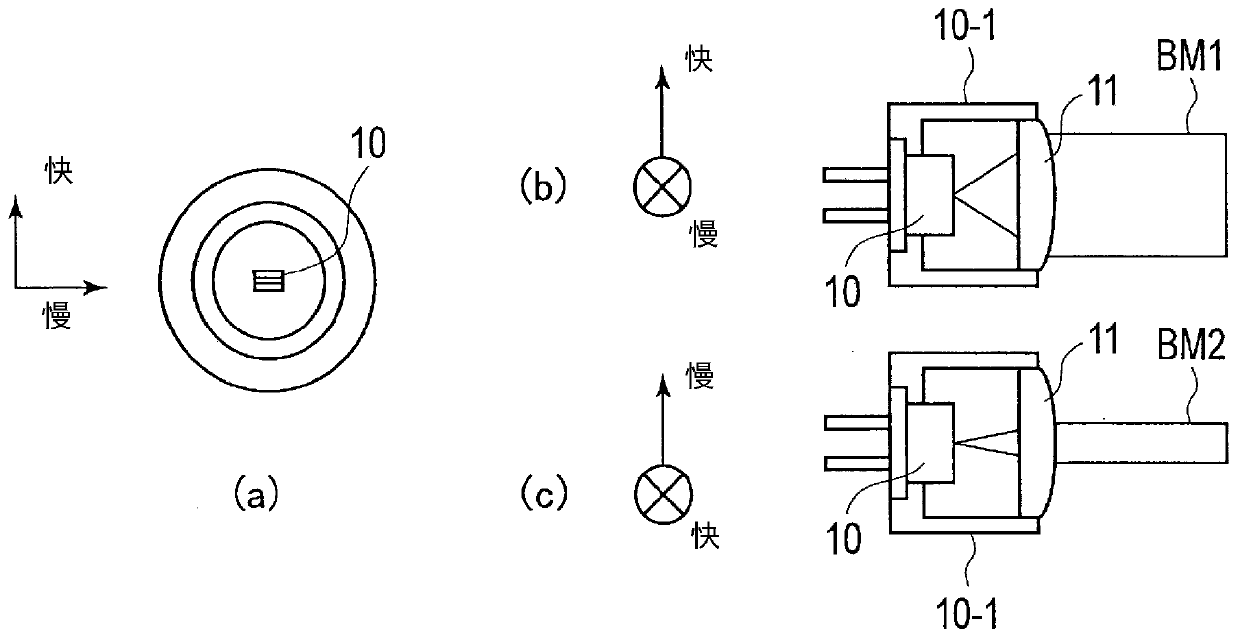

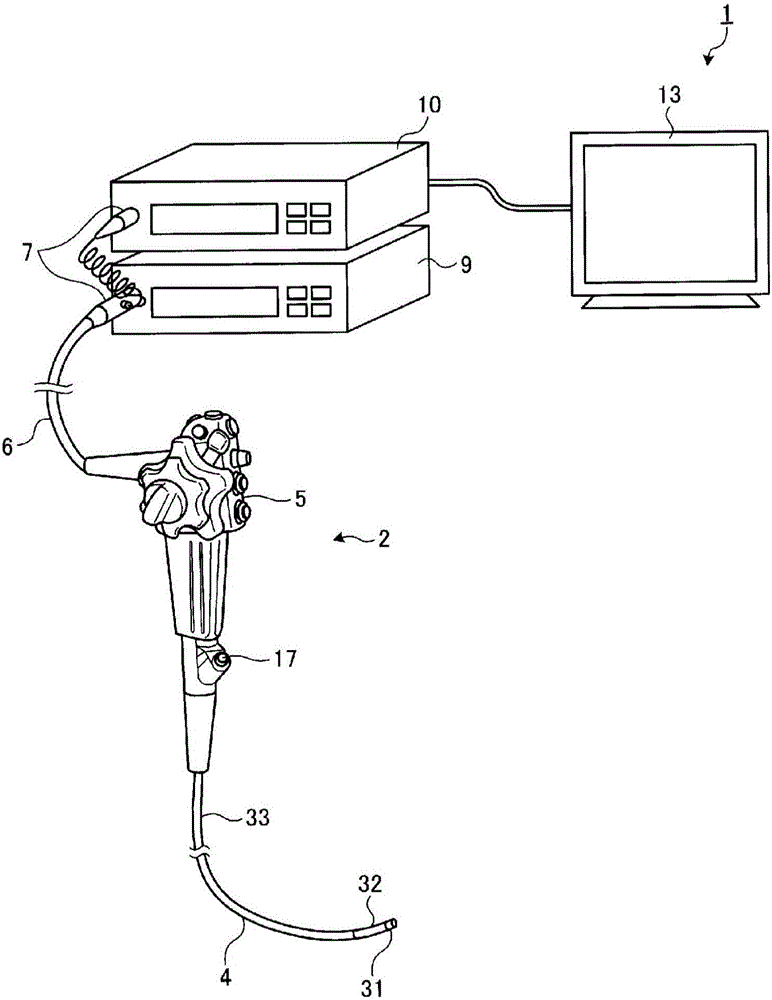

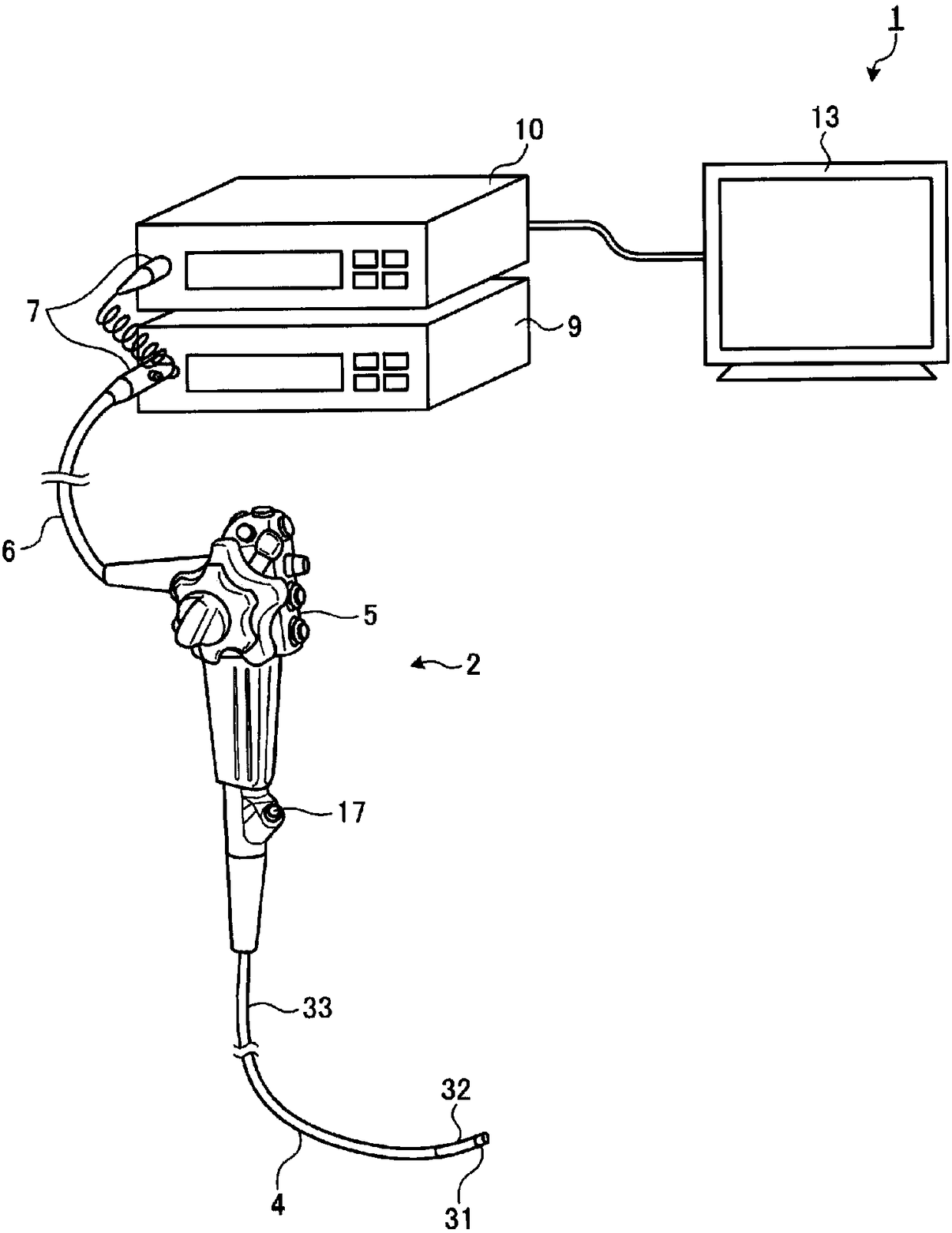

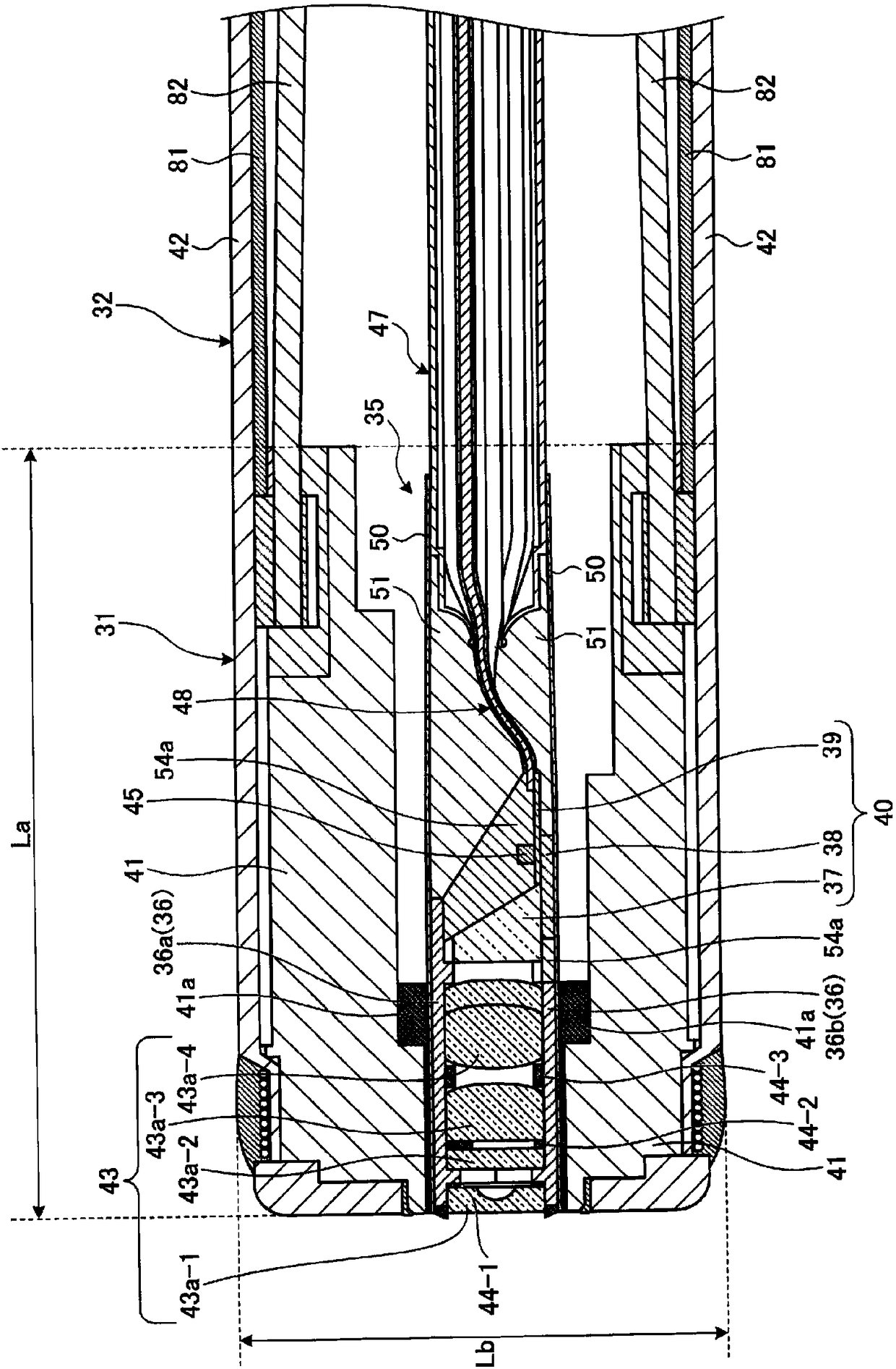

Actuator apparatus, image pickup apparatus and endoscopic apparatus

The invention provides an actuator apparatus, an image pickup apparatus and an endoscopic apparatus; by realizing the actuator apparatus including a simple and small structure, diameters of the image pickup apparatus of the actuator apparatus and the endoscopic apparatus can be thinned. The actuator apparatus (2) of the invention is characterized in that, the actuator apparatus (2) includes a moving unit which can freely move forwards and backwards; a force-urging unit (10) which urges the moving unit in one direction; and wires (8, 28) fixed to the moving unit, two ends of the wire are connected with a driving source which enables the moving unit to move in another direction against the urging force by the force-urging unit.

Owner:OLYMPUS CORP

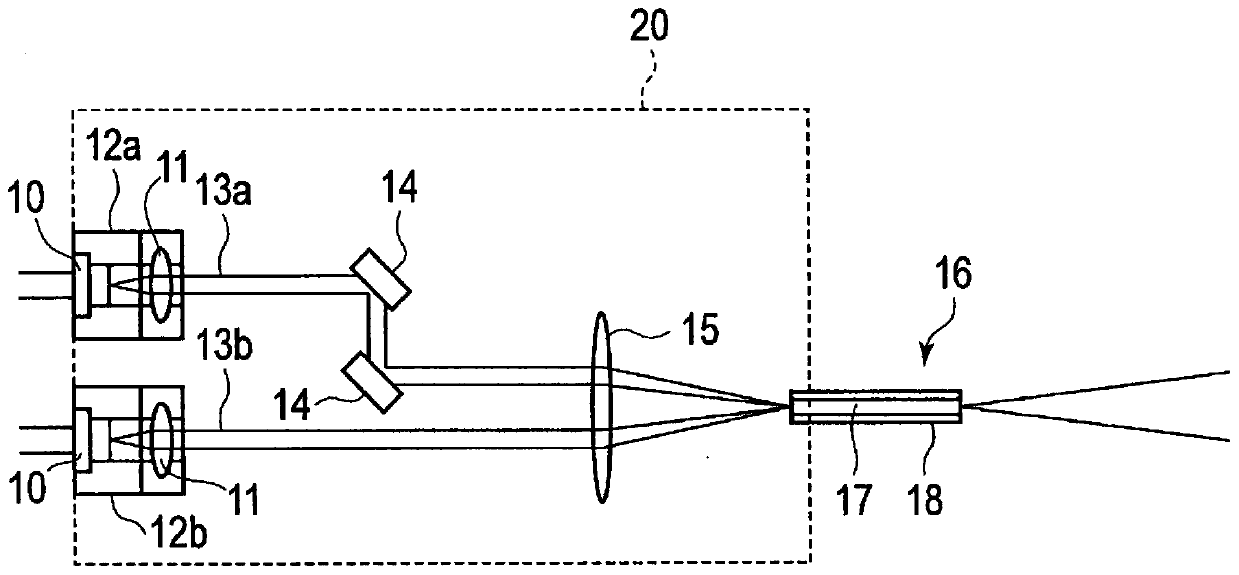

Laser device

InactiveCN109716189AReduce the angle of incidenceAchieve finer diameterSoldering apparatusCoupling light guidesFiberOptical axis

Provided is a laser device wherein a plurality of optical elements are provided correspondingly to a plurality of laser diodes, and collimate a plurality of beams emitted from the plurality of laser diodes. A plurality of selective transmission elements are provided correspondingly to the plurality of optical elements, and selectively transmit beams emitted from the plurality of laser diodes or beams emitted from the plurality of optical elements except for the outer periphery of the beams. One or more light traveling direction-control members control the light traveling directions of the plurality of beams having passed through the plurality of optical elements and the plurality of selective transmission elements, in order to move the plurality of beams to the vicinity of the optical axisof the fiber. A light-condensing unit condenses the plurality of beams emitted from the one or more light traveling direction-control members to the fiber.

Owner:SHIMADZU SEISAKUSHO CO LTD

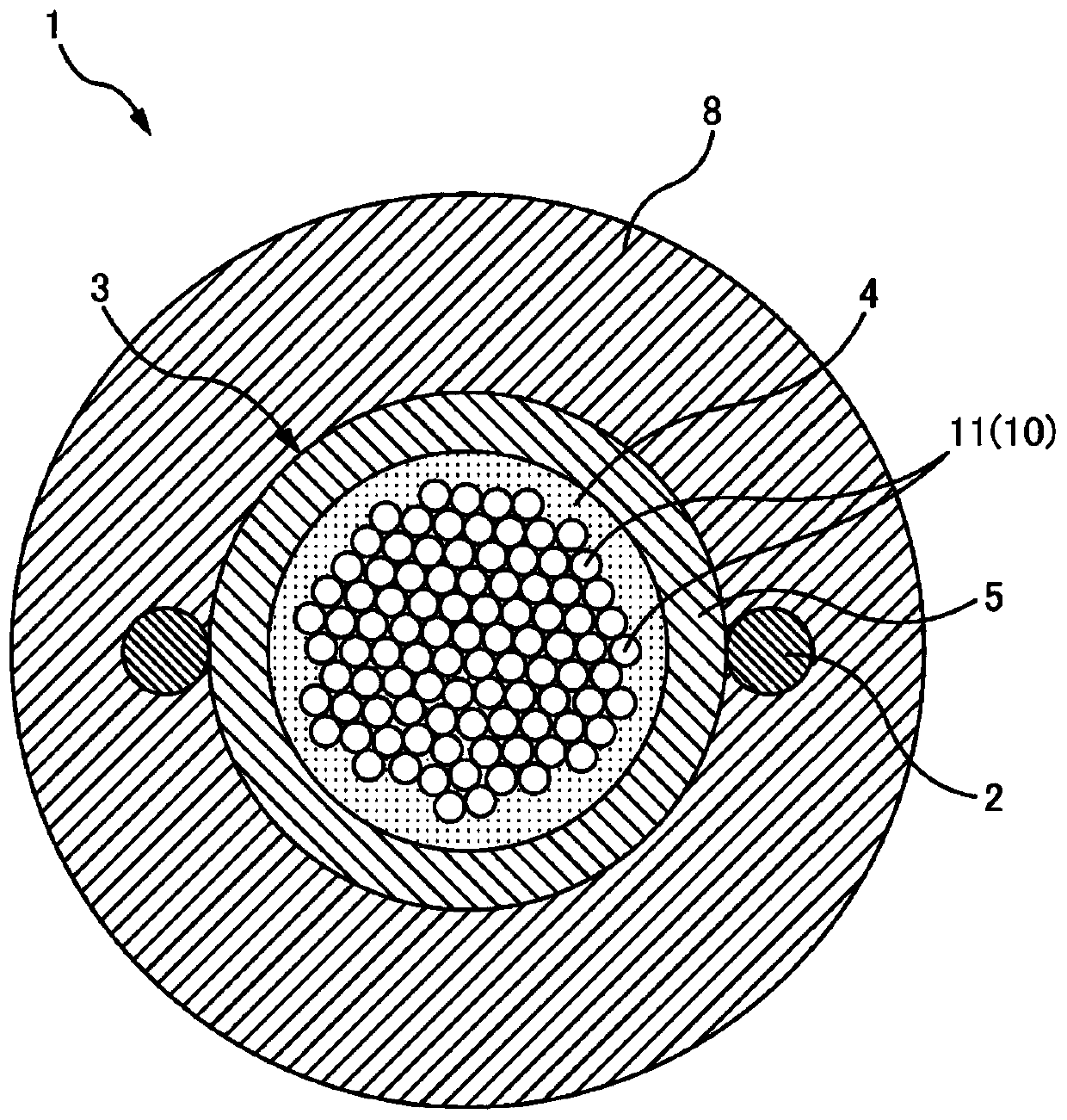

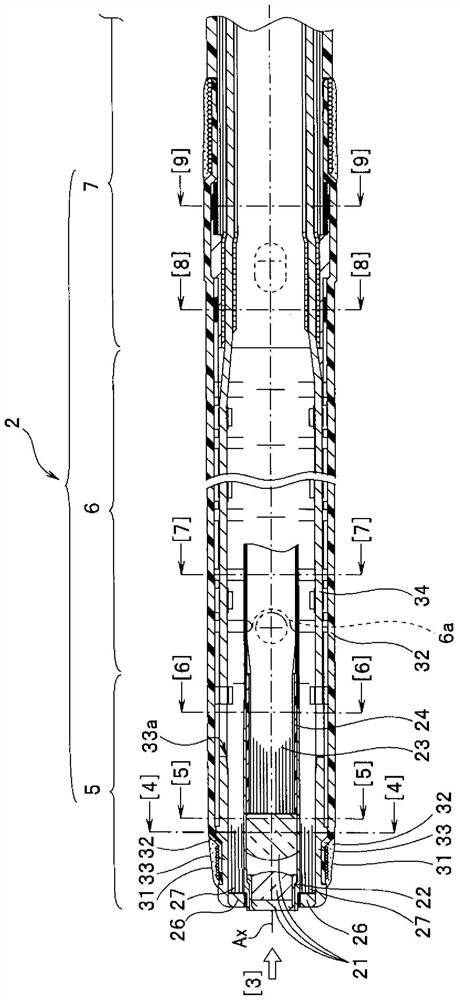

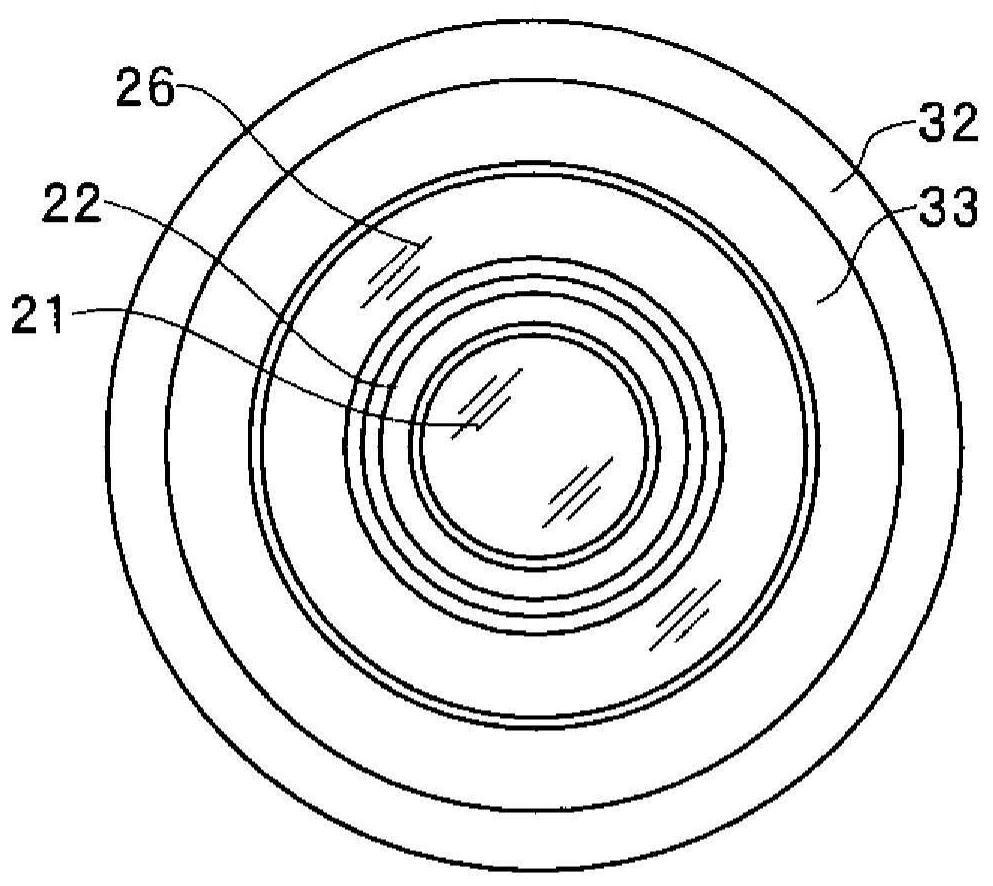

Ultrasonic endoscope

PendingCN114145775APrevent image degradationAchieve finer diameterDiagnostic probe attachmentSurgeryCoaxial cableMedicine

An ultrasonic endoscope is provided with: an insertion section including a tip section having an ultrasonic transducer array in which a plurality of ultrasonic transducers are arranged; a cable inserted through the insertion part; a substrate that electrically connects the plurality of ultrasonic transducers and a cable and is disposed at the tip portion, the cable having: a non-coaxial cable including a first cable bundle comprising a plurality of signal lines and a plurality of ground lines, and a first shield layer covering the first cable bundle; and a sheath covering a second cable bundle comprising a plurality of non-coaxial cables, the substrate having a plurality of electrode pads connected to the plurality of ultrasonic transducers, the first cable bundles being led out from the cables, the signal lines of the first cable bundles being led out and electrically connected to the electrode pads of the substrate, and the signal lines of the second cable bundles being led out and electrically connected to the electrode pads of the substrate. The plurality of ultrasonic vibrators are configured from a plurality of drive units that are simultaneously driven, the plurality of signal lines of each first cable bundle are connected to the plurality of electrode pads of each drive unit to constitute a signal line group, and the signal line group includes at least two types of signal lines having different lengths from the tip of the first cable bundle.

Owner:FUJIFILM CORP

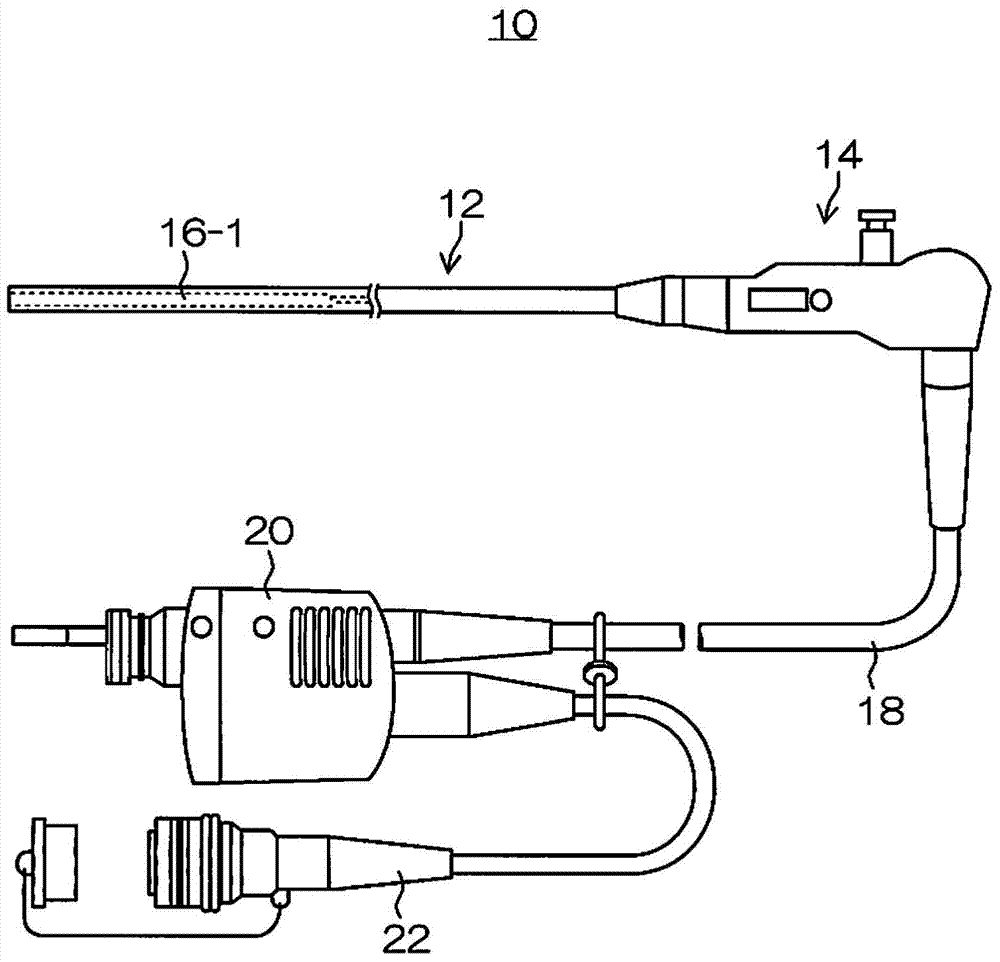

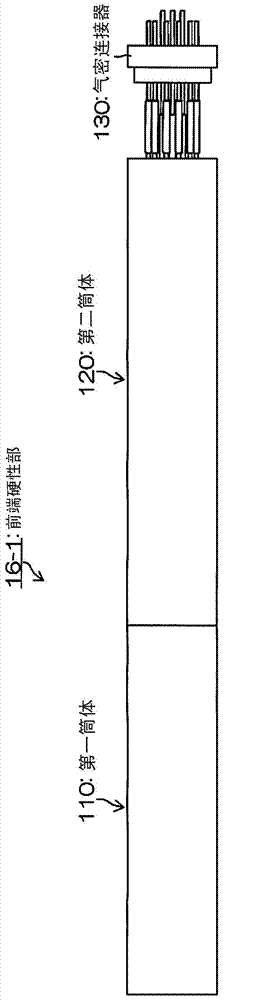

Endoscope and method for manufacturing same

ActiveCN104510433AEasy to work with wiresAchieve finer diameterSurgeryEndoscopesEngineeringAir tightness

Owner:FUJIFILM CORP

endoscope

ActiveCN106231978BAchieving Desired Optical PerformanceAchieve finer diameterSurgeryEndoscopesFiberEndoscope

Owner:OLYMPUS CORP

Conductive wire, manufacturing method of conductive wire, and wiring structure of conductive wire

ActiveCN105408963BImprove flexibilityEasy wiringPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsWire rodElectrical conductor

A conductive wire (L) consisting of a single-core wire (4) and a twisted wire (5), the single-core wire is formed by surrounding a conductor (6) with a coating (7), and the twisted wire is formed by A plurality of wires (9) are twisted and formed by surrounding the plurality of wires with a coating (10), and the coating (7) is stripped off at least one of both ends in the length direction of the single-core wire (4) And the conductor (6) is exposed. A crushed portion (8) crushed into a flat plate shape is formed on the exposed conductor (6). The lead wire (9) exposed at the end of the twisted wire (5) is bonded to the crushed portion (8) by ultrasonic welding.

Owner:SUMITOMO WIRING SYST LTD

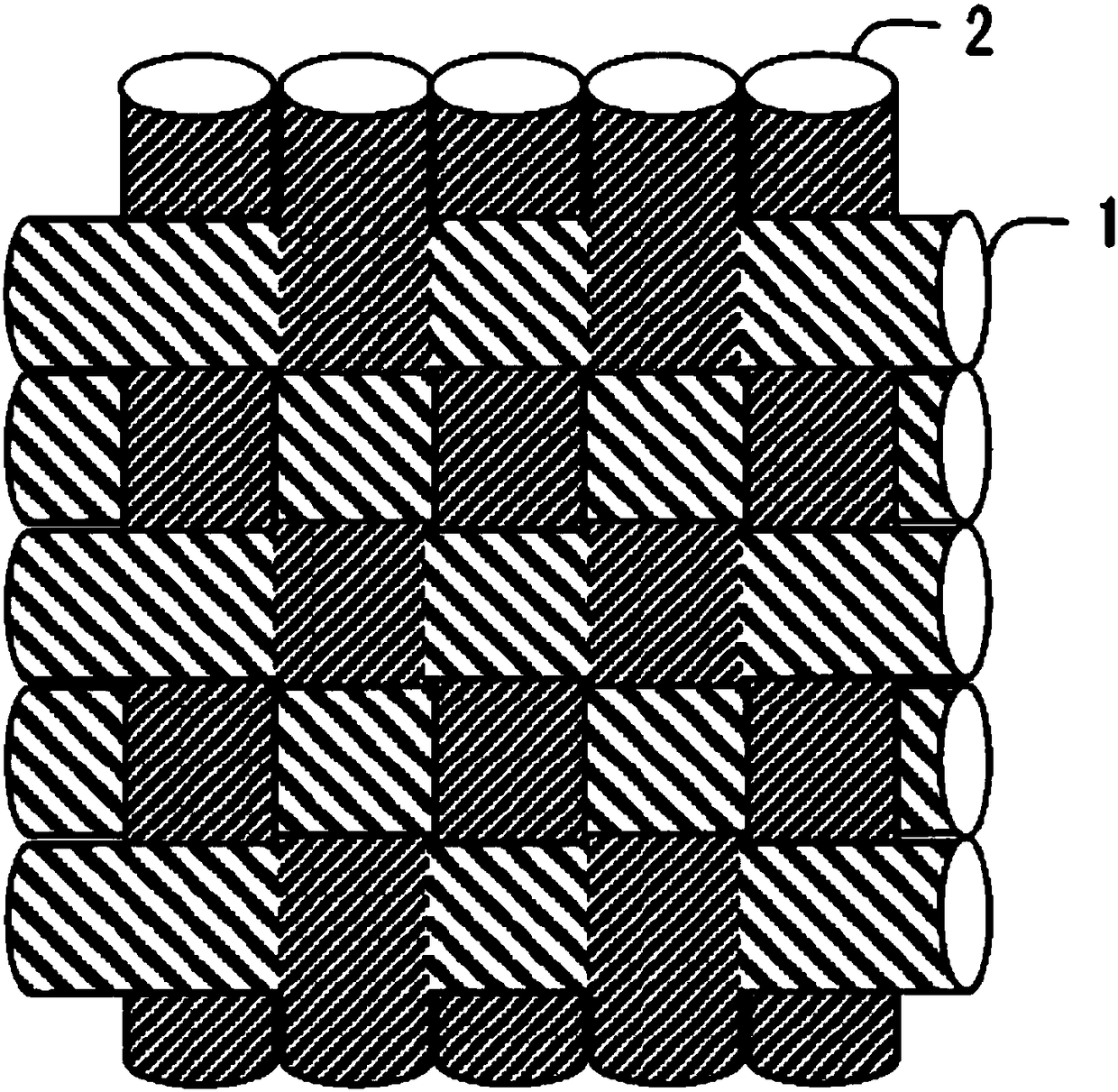

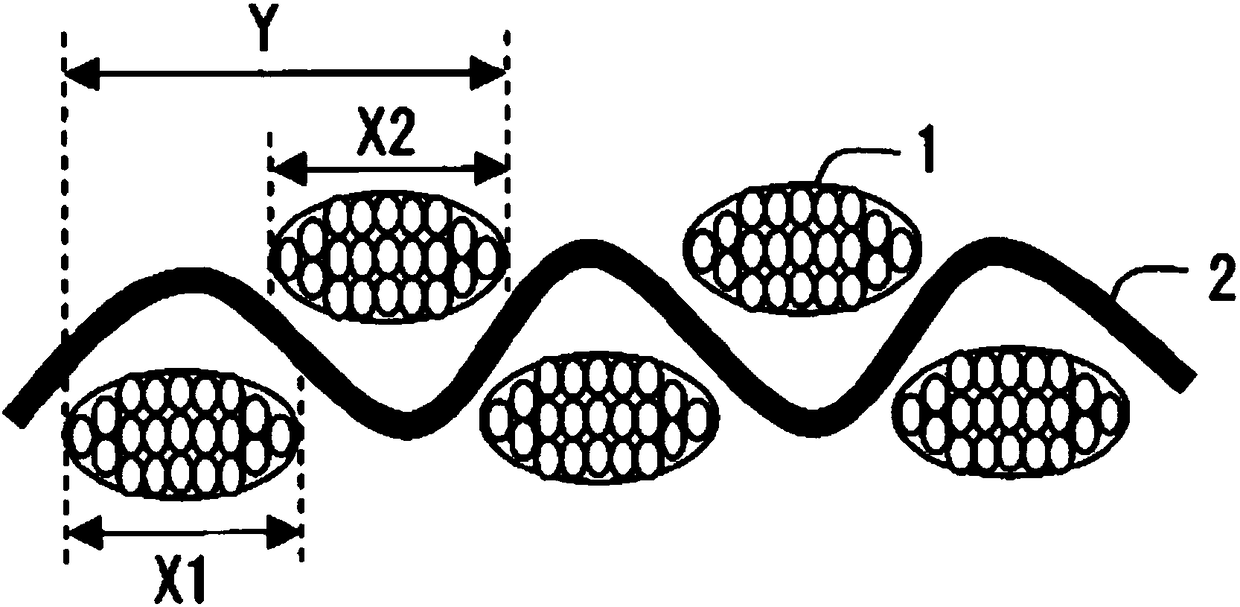

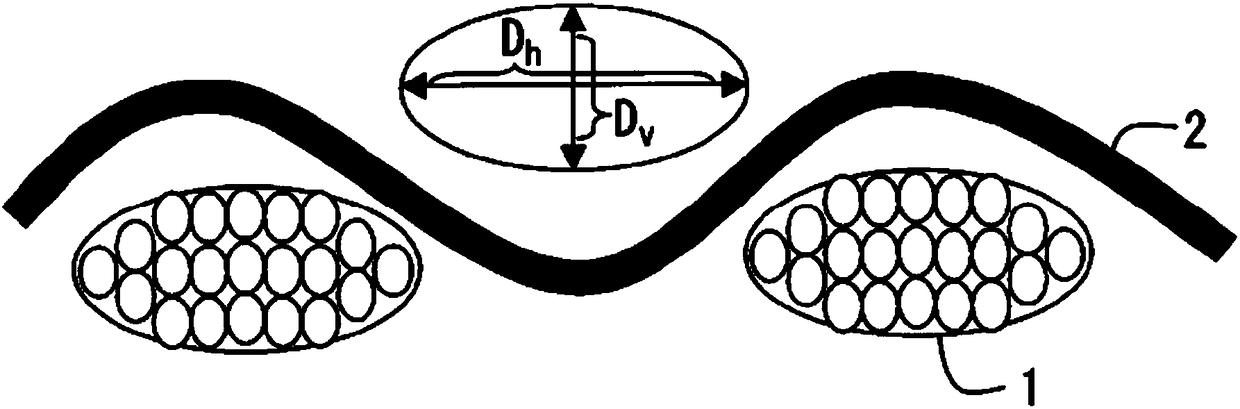

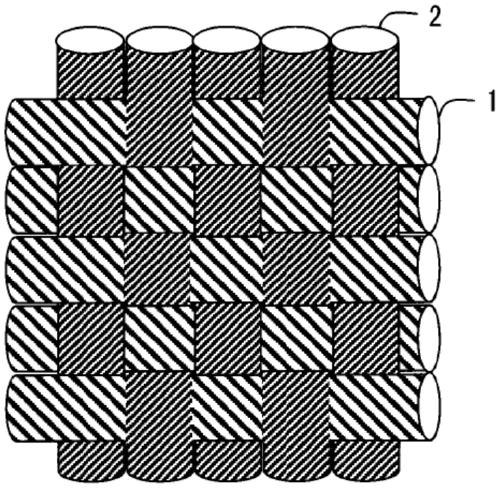

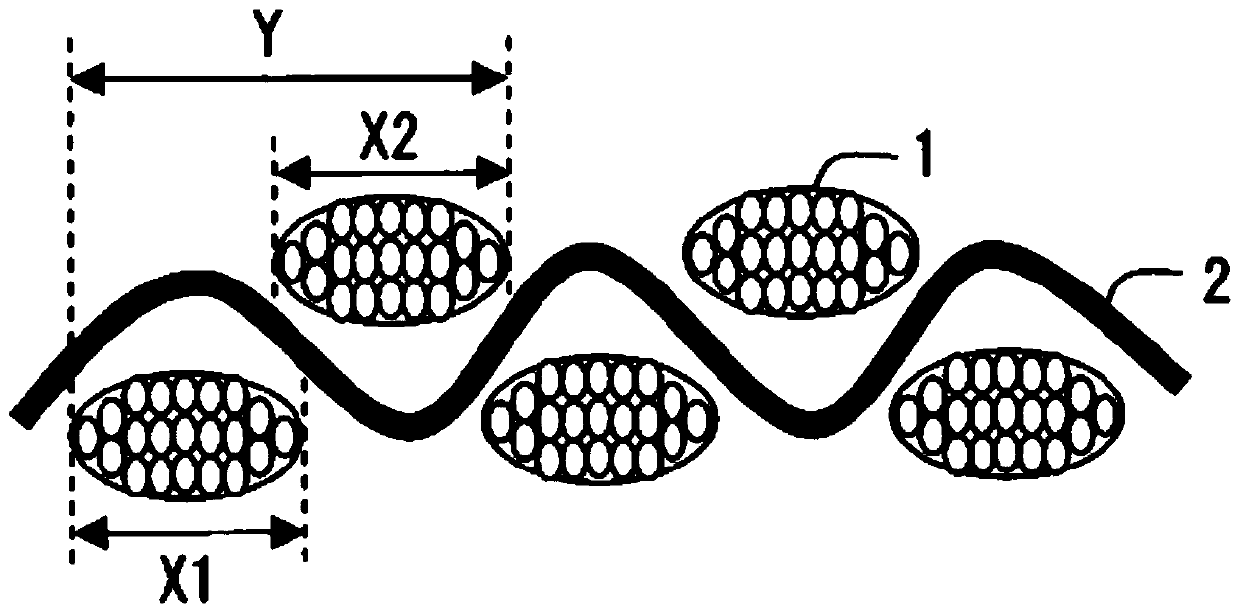

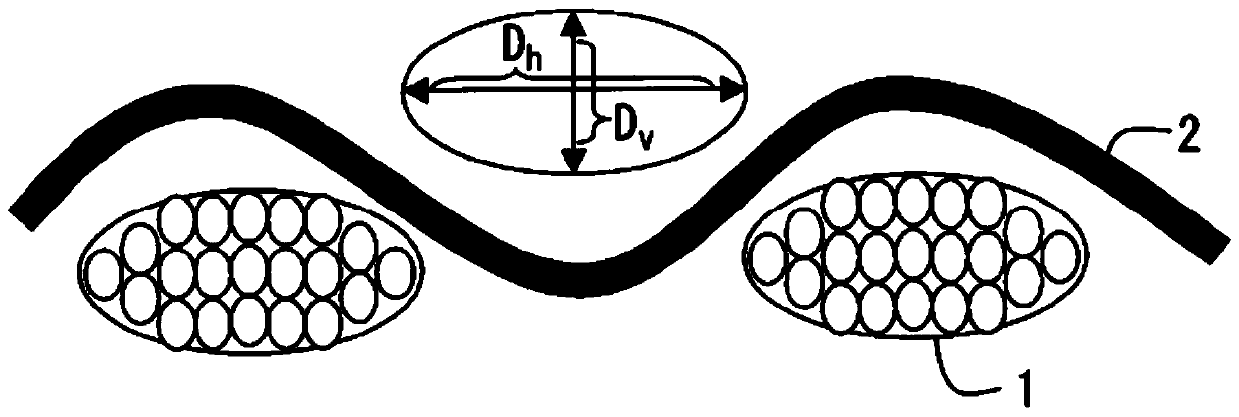

Loose tube, loose tube type optical fiber cable, single-core separation method of loose tube optical fiber ribbon, method of manufacturing loose tube, and method of gathering multiple optical fibers

The invention provides a loose tube, a loose tube type optical fiber cable, a method for separating single cores of an optical fiber ribbon of the loose tube, a method for manufacturing the loose tube and a method for gathering multiple optical fibers. The diameter reduction of loose tubes with optical fiber ribbons is realized. The present invention is a loose tube provided with a plurality of optical fibers and a tube for accommodating the plurality of optical fibers together with a filler. The plurality of optical fibers are constituted by discontinuously fixed optical fiber ribbons in which connecting portions for connecting adjacent optical fibers are discontinuously arranged, and in a state where the plurality of optical fibers constituting the discontinuously fixed optical fiber ribbons are bundled, The discontinuously fixed optical fiber ribbon is arranged in the sleeve.

Owner:THE FUJIKURA CABLE WORKS LTD

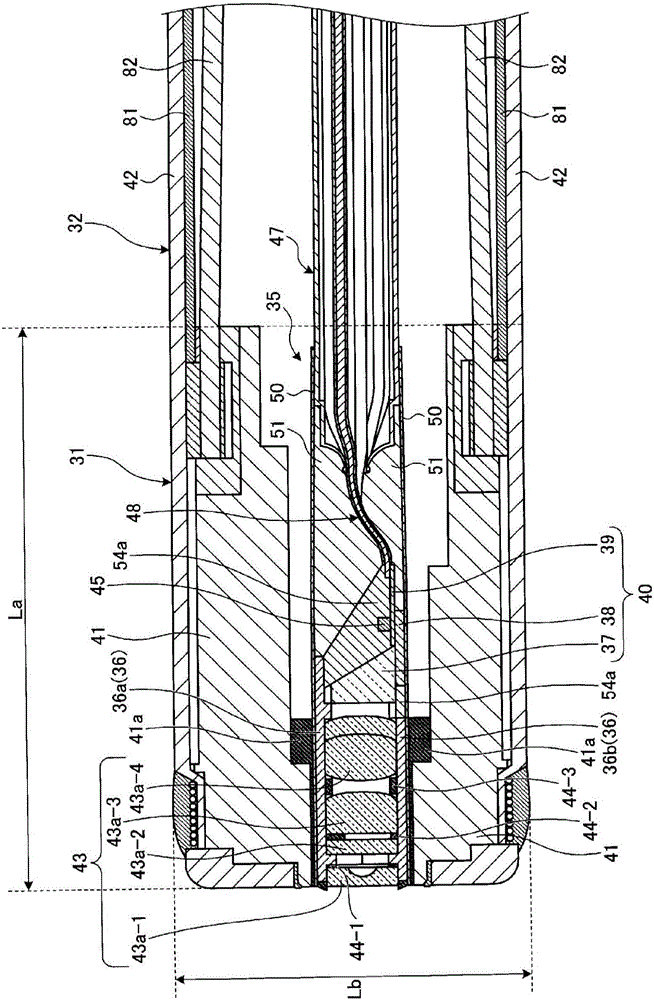

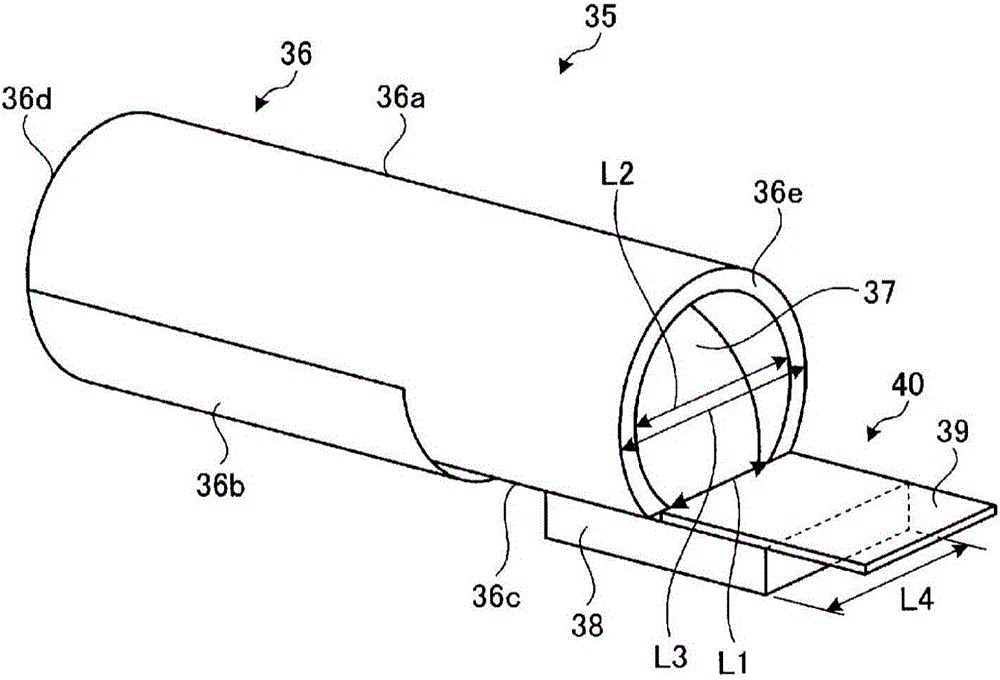

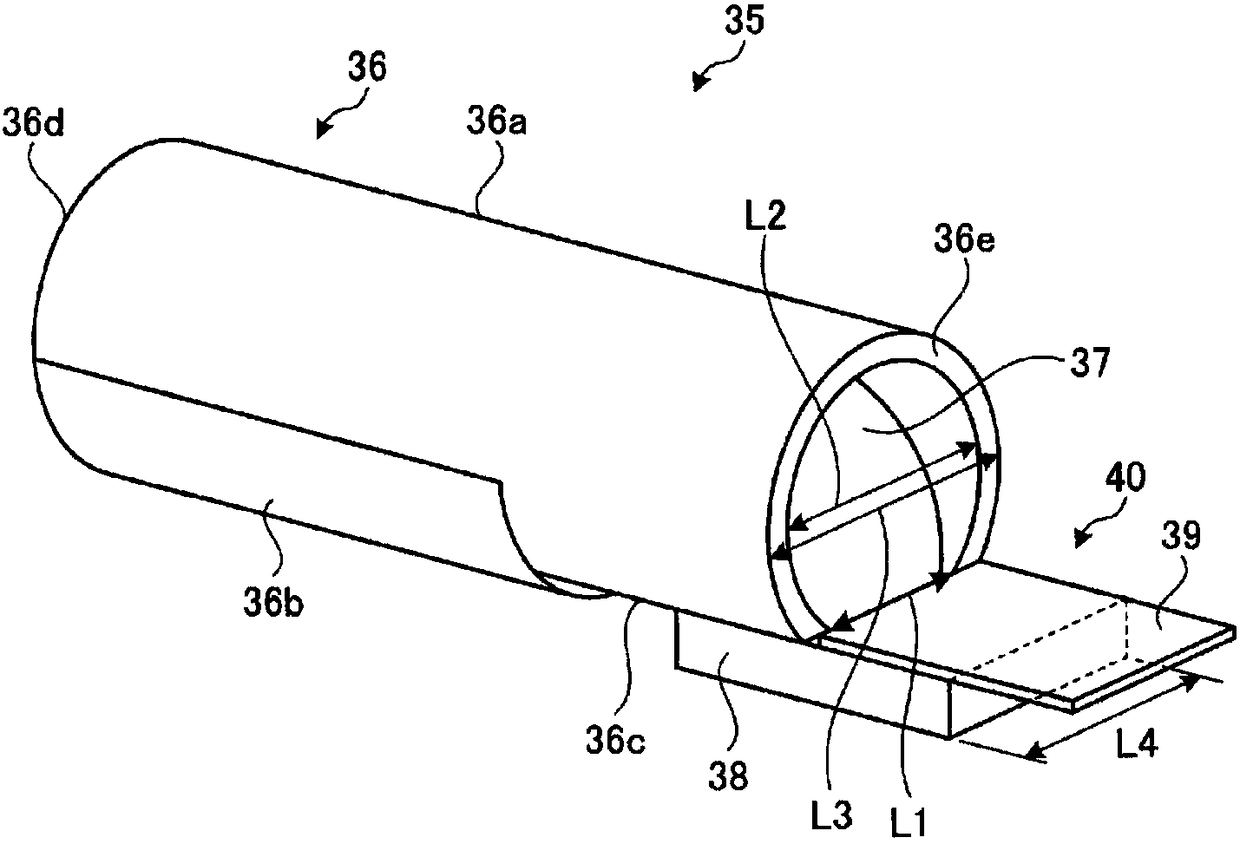

Imaging device and endoscope device

Provided are a compact imaging device and endoscope device. The imaging device (35) is provided with: an optical member holder (36) that is hollow with both ends being open, and has a notched section (36c) at the side surface at one end; an objective lens (43) that is installed within the optical member holder (36) and that focuses light entering from the other end of the optical member holder (36); a prism (37) that is installed within the optical member holder (36) and that reflects light focused by the objective lens (43); an imaging element (38) that receives the light reflected by the prism (37) and that generates an electrical signal by means of performing photoelectric conversion; and a substrate (39) that is electrically connected to the imaging element (38). The prism (37) is characterized by at least a portion of the outer peripheral surface thereof forming a cylindrical surface, the cylindrical surface contacting the interior of the optical member holder (36), and at least a portion of the imaging element (38) being attached to the side surface of the optical member holder (36) via the notched section (36c).

Owner:OLYMPUS CORP

Camera and Endoscope Devices

To provide an imaging device and an endoscope device capable of miniaturization. The imaging device (35) of the present invention is characterized in that it has: an optical component holder (36), which is formed in a hollow shape with both ends open, and has a notch (36c) on the side of one end; an objective lens (43), which is assembled In the inside of the optical component support (36), the light incident from the other end of the optical component support (36) is converged; the prism (37), which is assembled in the inside of the optical component support (36), makes the objective lens (43) The converging light reflection; the imaging element (38), which generates an electric signal by accepting the light reflected by the prism (37) and performing photoelectric conversion; and the substrate (39), which is electrically connected with the imaging element (38), and the prism ( 37) at least a part of the outer peripheral surface is formed as a cylindrical surface, the prism (37) is in contact with the inside of the optical component holder (36) with the cylindrical surface, and at least a part of the imaging element (38) is installed on the Side of the Optics Holder (36).

Owner:OLYMPUS CORP

Printer

ActiveCN102189813BEasy loading and unloadingImprove reliabilityOther printing apparatusFixed frameEngineering

Provided is a printer in which attachment and detachment manipulation of a platen roller can be easily performed, in which the platen roller can be retained with high reliability at a time of attachment, and in which downsizing of the entire printer is achieved due to use of the platen roller smaller in diameter. A printer (1) includes: a rocking member (22) including a bearing portion (22a) for axially supporting a platen roller (21); a latch member (23) coupled to the rocking member so as to be rotatable about a rotary axis (L2) that is non-coaxial with and parallel to a platen axis (L1); a protrusion (31 a) provided to the latch member; and a stationary frame (40) to which a recording head (42) is fixed, in which: the stationary frame includes a first recess (45) into which the bearing portion is disengageably fitted, the first recess retaining the platen roller at a position of facing the recording head, and a second recess (46) into which, after the bearing portion is fitted, the protrusion is disengageably fitted; and the bearing portion is undisengageable from inside the first recess while the protrusion is fitted, and is disengageable from inside the first recess after the protrusion is disengaged.

Owner:SEIKO INSTR INC

Ultrasonic endoscope

PendingCN114145776ASuppress disconnectionAchieve finer diameterSurgeryEndoscopesCoaxial cableUltrasonic Endoscopy

Owner:FUJIFILM CORP

Ultrasonic probe and ultrasonic endoscope with ultrasonic probe

ActiveCN101466314BAchieve finer diameterUltrasonic/sonic/infrasonic diagnosticsSurgeryElectrical connectionEngineering

The diameters of an ultrasonic probe and an ultrasonic endoscope are decreased, and electrical connection in respect of a signal line extending from the ultrasonic vibrator is reliably and easily made. The ultrasonic probe comprises vibrator wiring pads (102) provided at the front end of an ultrasonic vibrator printed board (101) where signal patterns for signal transmission / reception of ultrasonic vibrators are formed, flexible printed board wiring pads (108) arranged in line along the longitudinal axis of the ultrasonic vibrator printed board (101), second signal patterns (106) connected between the vibrator wiring pads (102) and the flexible printed board wiring pads (108) and bent generally 90 degrees at intermediate portions, and a relay flexible printed board (121) connected to the flexible printed board wiring pads (108) and used to change the direction of the signal patterns to the longitudinal axis direction.

Owner:OLYMPUS CORP

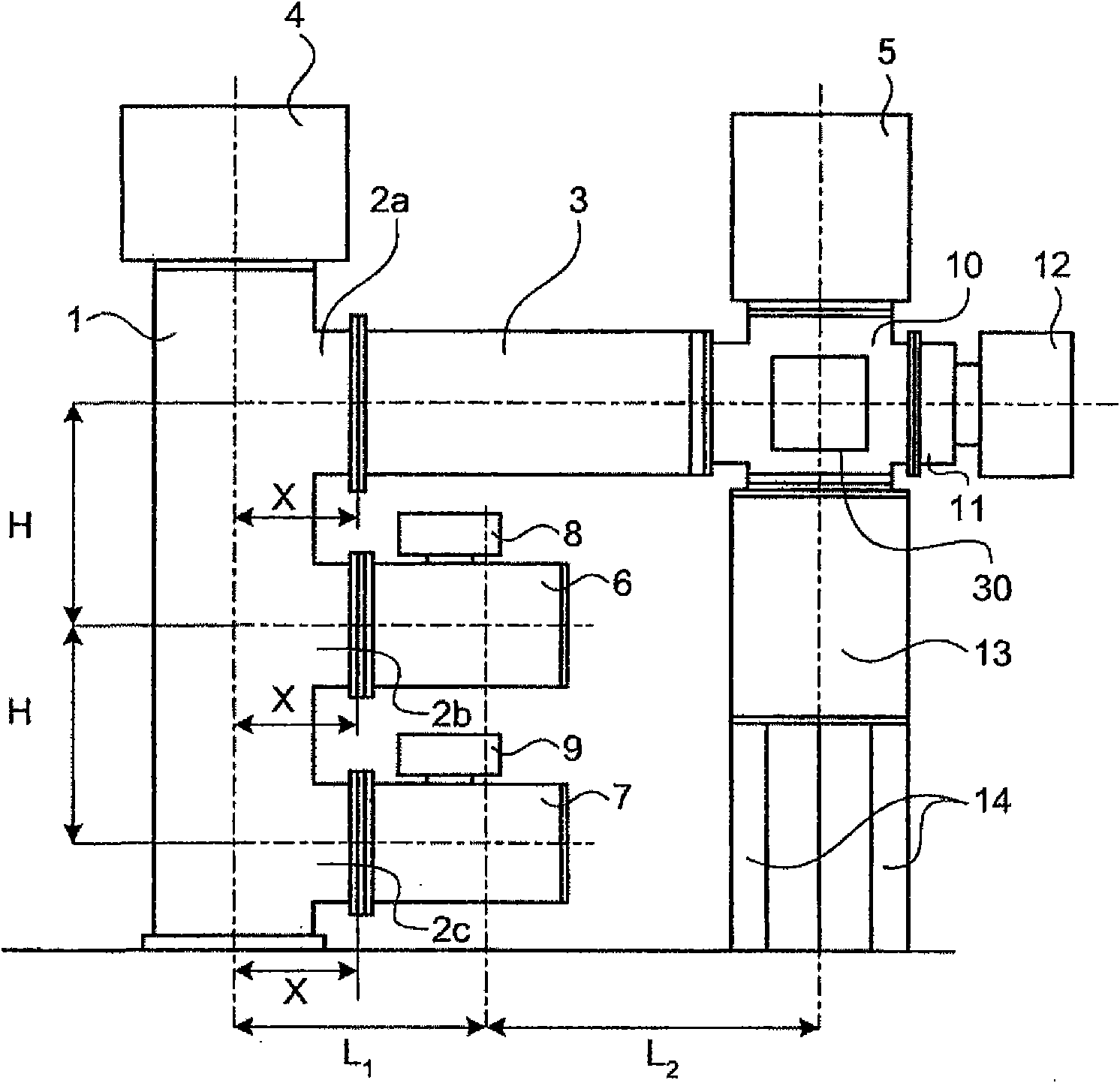

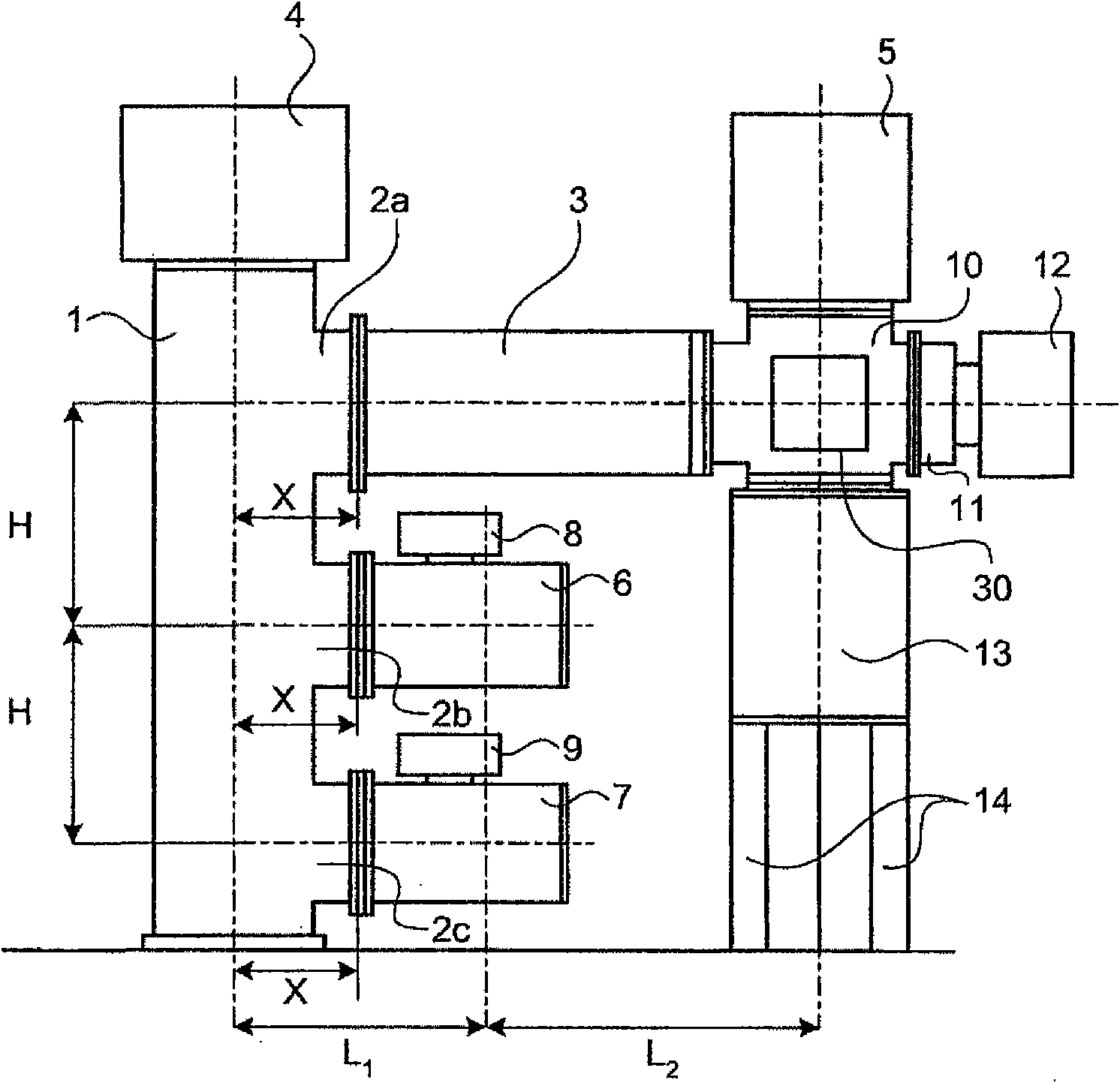

Gas insulation switching device

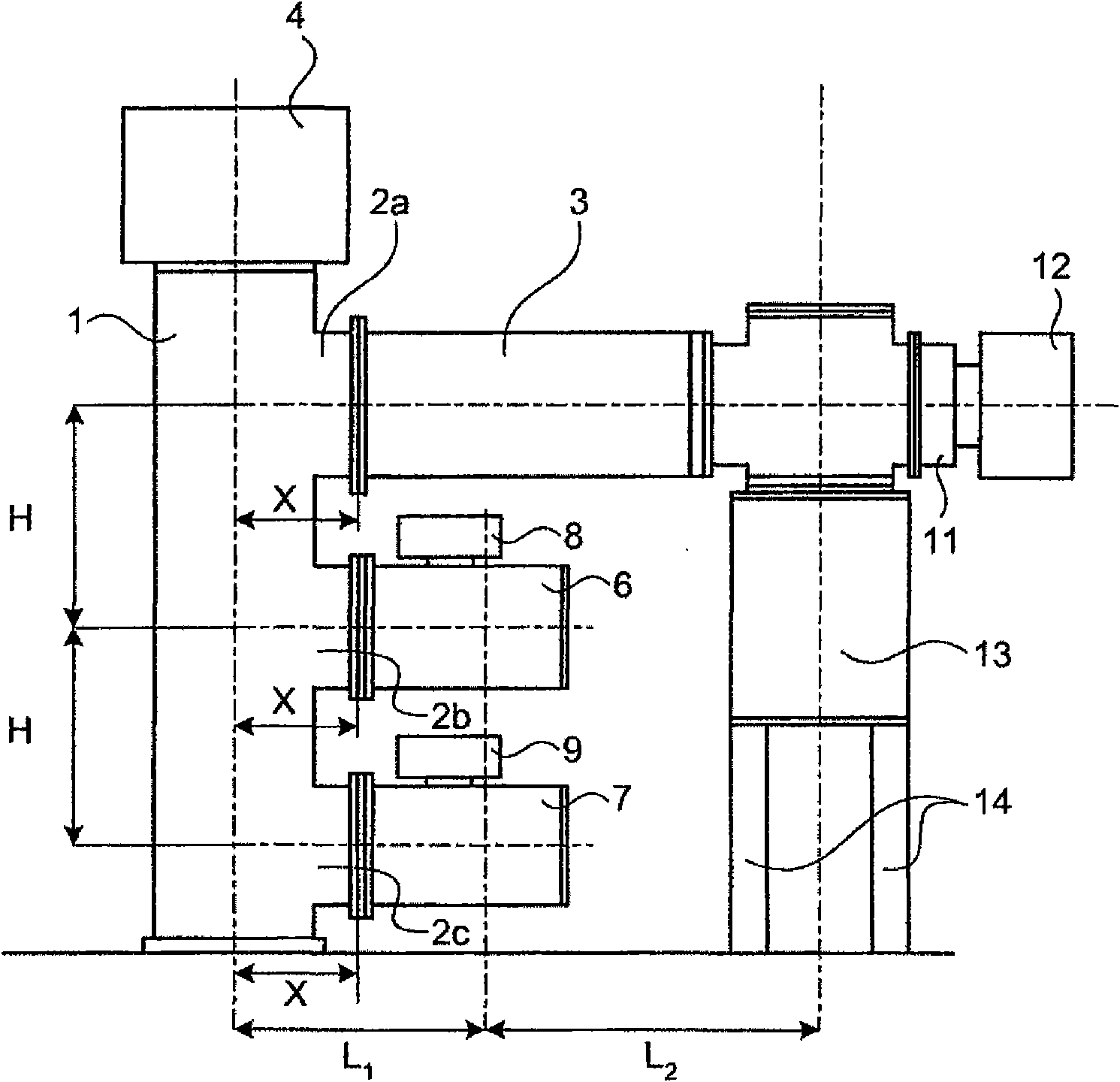

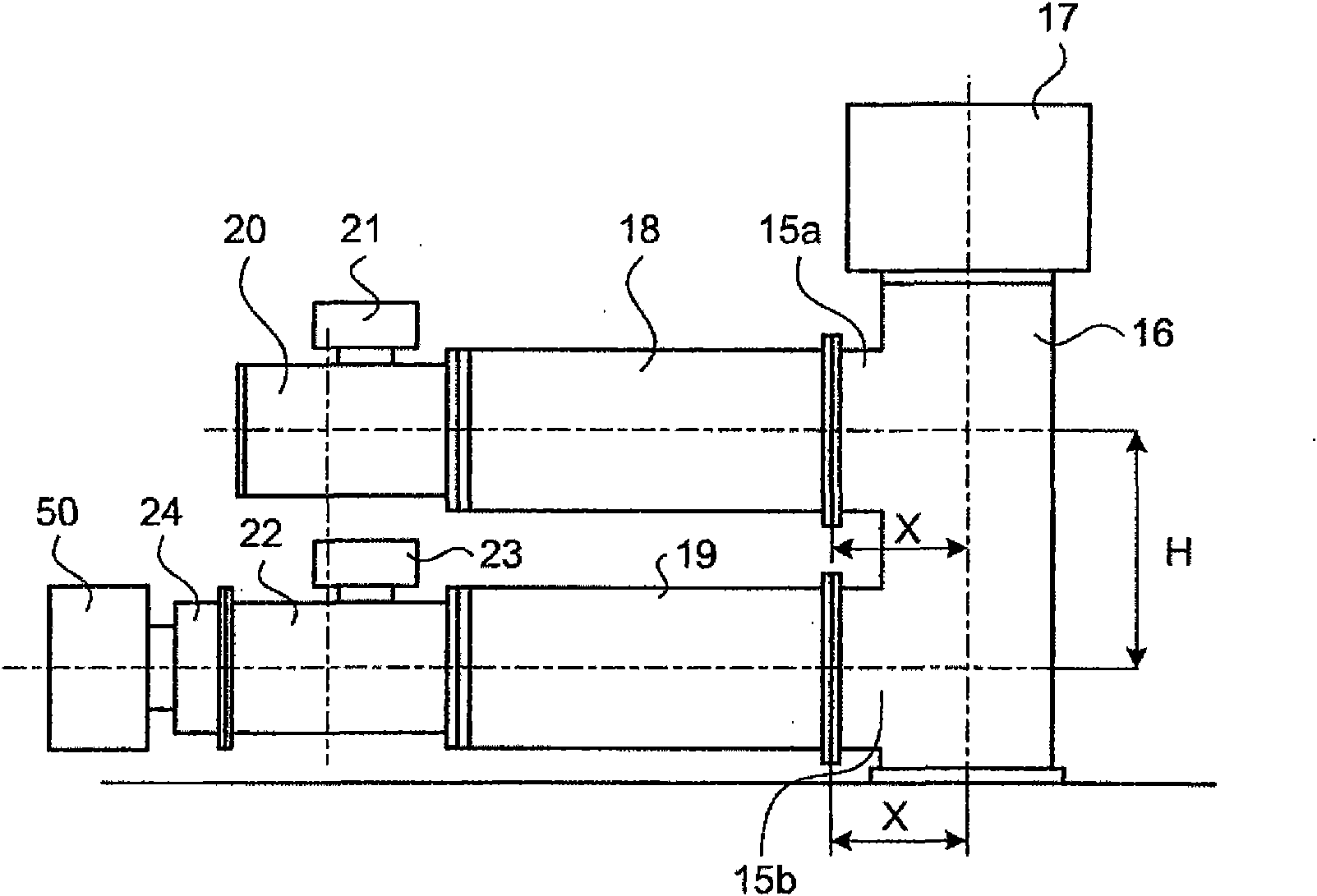

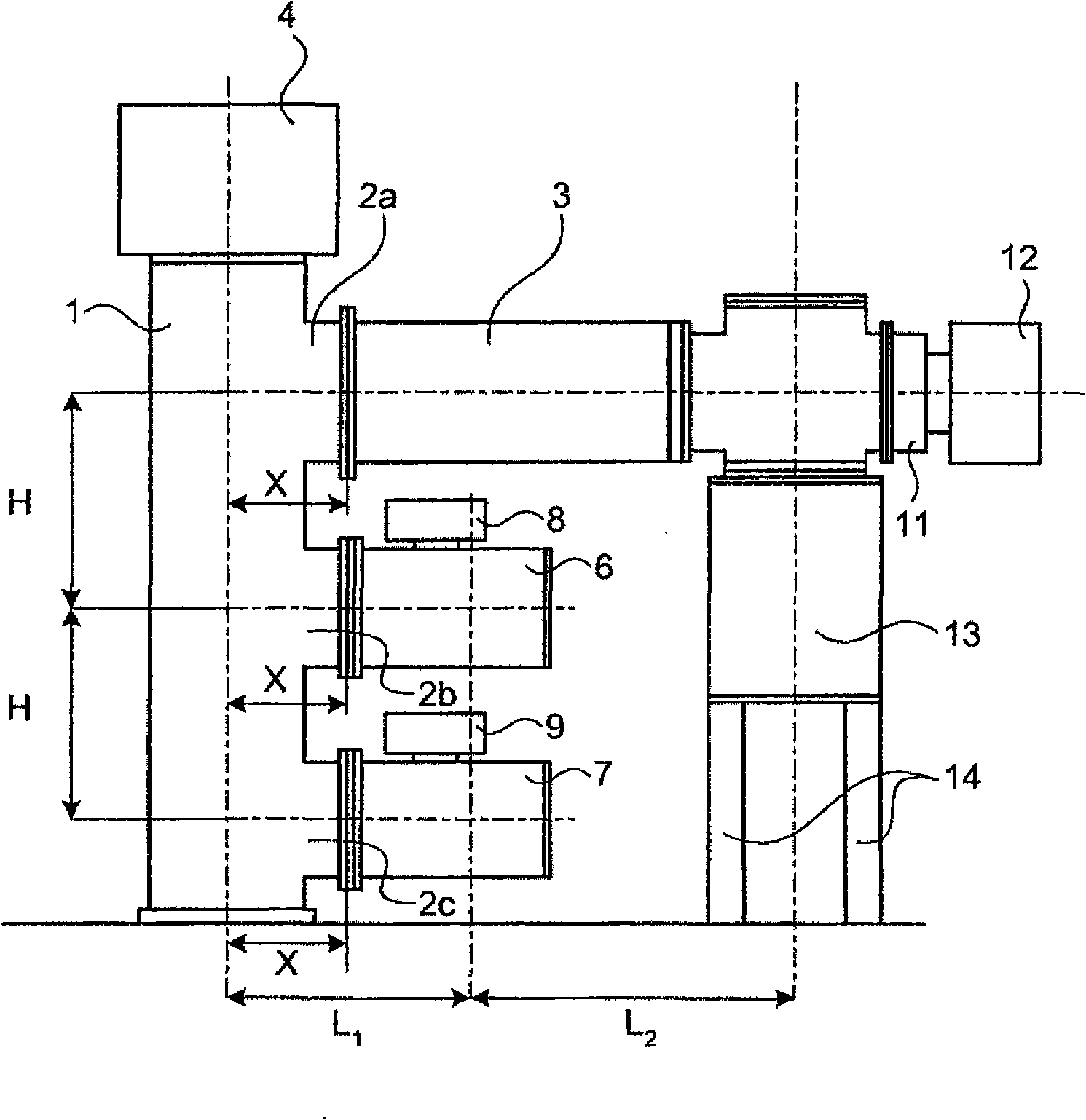

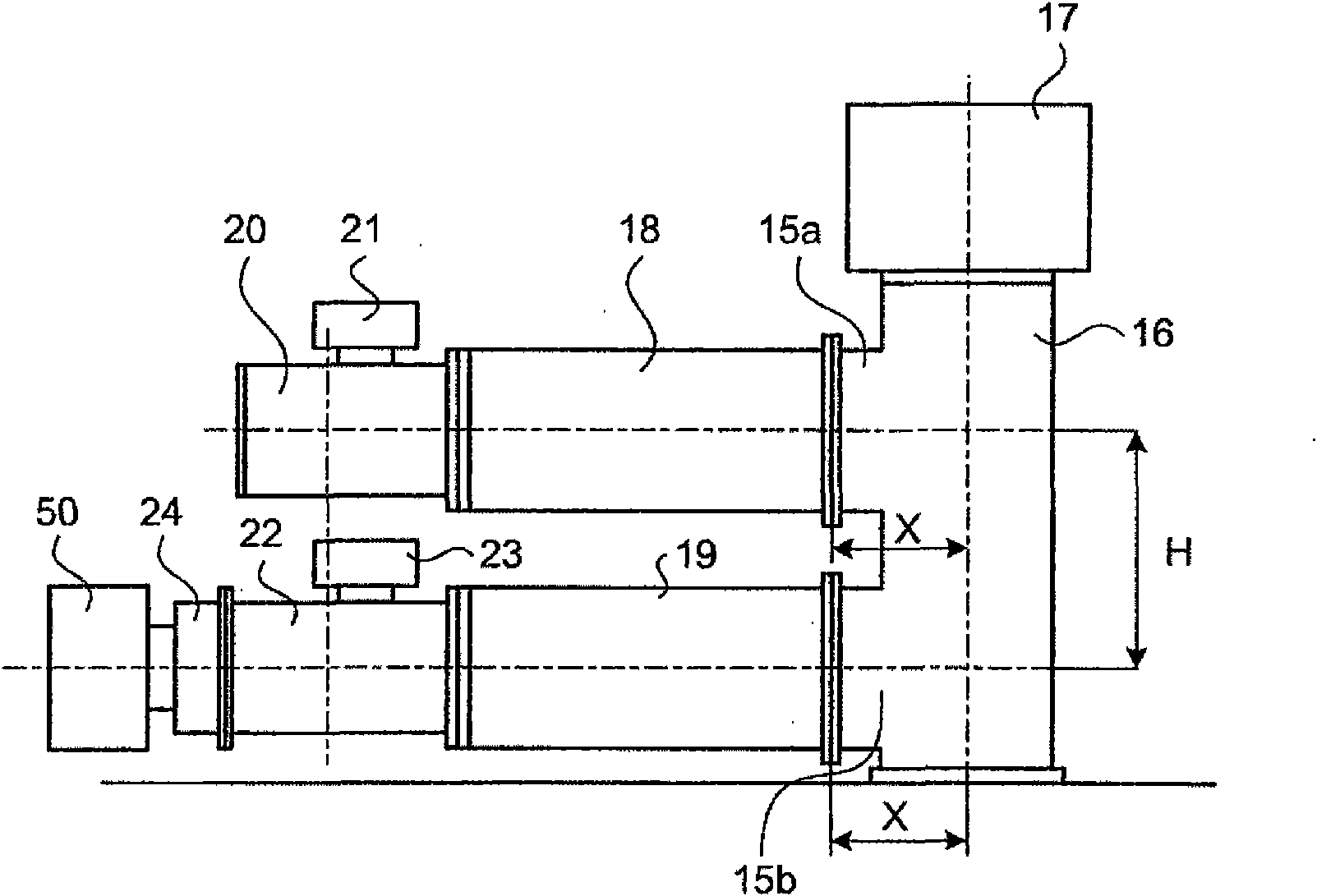

InactiveCN101669260AAchieve finer diameterSimplify the routing structureBus-bar/wiring layoutsGas-insulated substationsElectricityBusbar

In a multi-busbar system gas insulated switchgear, a power transmission / reception line unit (I) is constituted by providing a plurality of branch lead-out ports at regular intervals (interval H) along a vertical direction on the lateral side of a tank of a vertical-type circuit breaker, connecting a line-side device to the uppermost branch lead-out port, connecting the busbar-side devices to the lower branch lead-out ports, and arranging the line-side device to face the circuit breaker while placing multiple busbars therebetween. In a busbar link line unit (III), the tank length of a vertical-type circuit breaker is shorter than the tank length of the circuit breaker by the interval H, and an interval between a plurality of branch lead-out ports for busbar-side-device connection that are provided on the later side of the tank of the circuit breaker along a vertical direction is also the interval H.

Owner:MITSUBISHI ELECTRIC CORP

medical cloth

ActiveCN108472122BThe overall thickness is thinHas tear strengthStentsFilament/thread formingMechanical engineeringBiomedical engineering

Owner:ASAHI KASEI KK

Optical collimator

The light collimator has a sleeve, a partially spherical lens, and a capillary holding an optical fiber. The sleeve has an inner bore concentric with its outer peripheral surface. The partially spherical lens has a cylindrical part inserted into the inner hole of the sleeve and light-transmitting spherical surfaces arranged at both ends of the cylindrical part. The optical axis of the transparent spherical surface is located at a position eccentric to the central axis of the outer peripheral surface of the sleeve. The capillary is inserted into the inner hole of the sleeve, the optical fiber is fixed at a position eccentric to the central axis of the outer peripheral surface of the sleeve, and the inclined end surface of the optical fiber is directed toward the partially spherical lens.

Owner:NIPPON ELECTRIC GLASS CO LTD

endoscope

ActiveCN108463154BEfficient configurationAchieve finer diameterSurgeryEndoscopesEngineeringMechanical engineering

Owner:OLYMPUS CORP

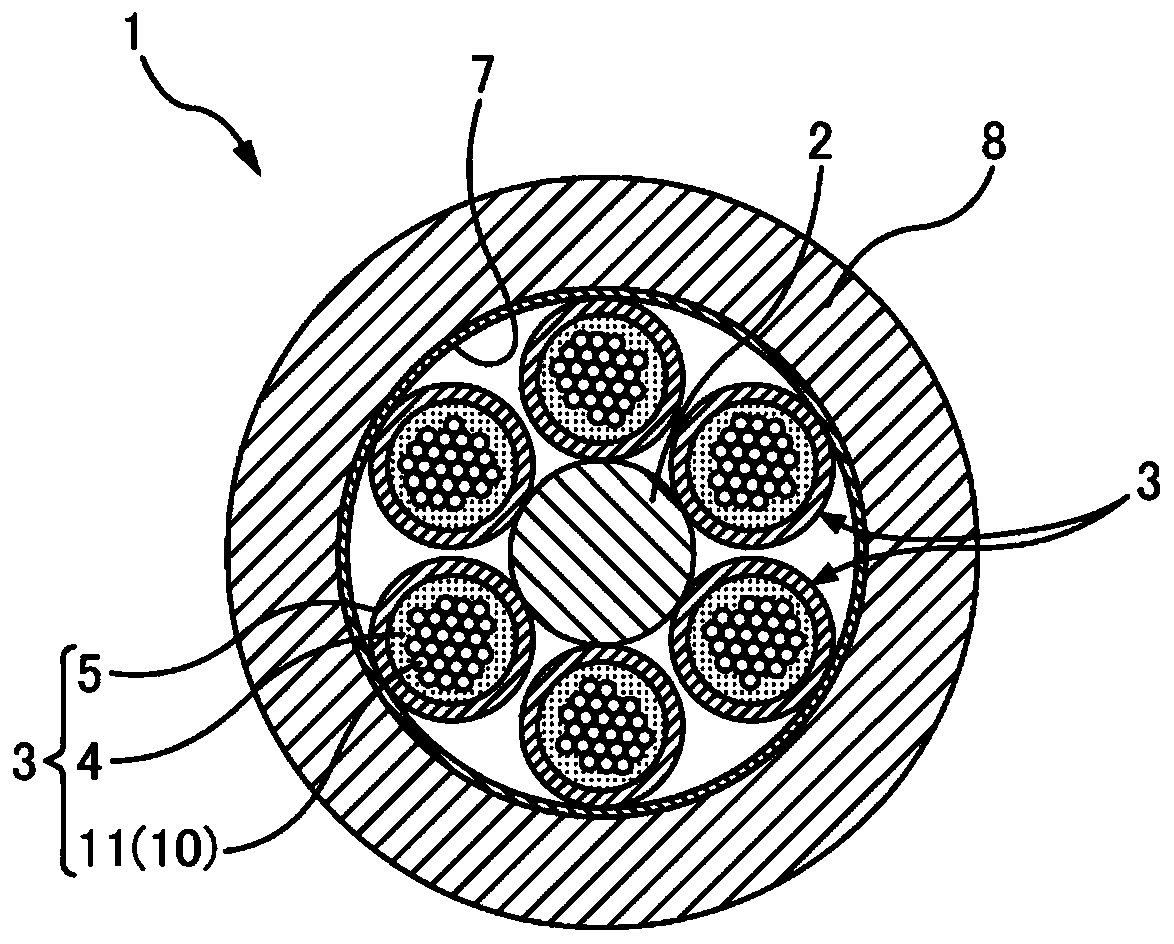

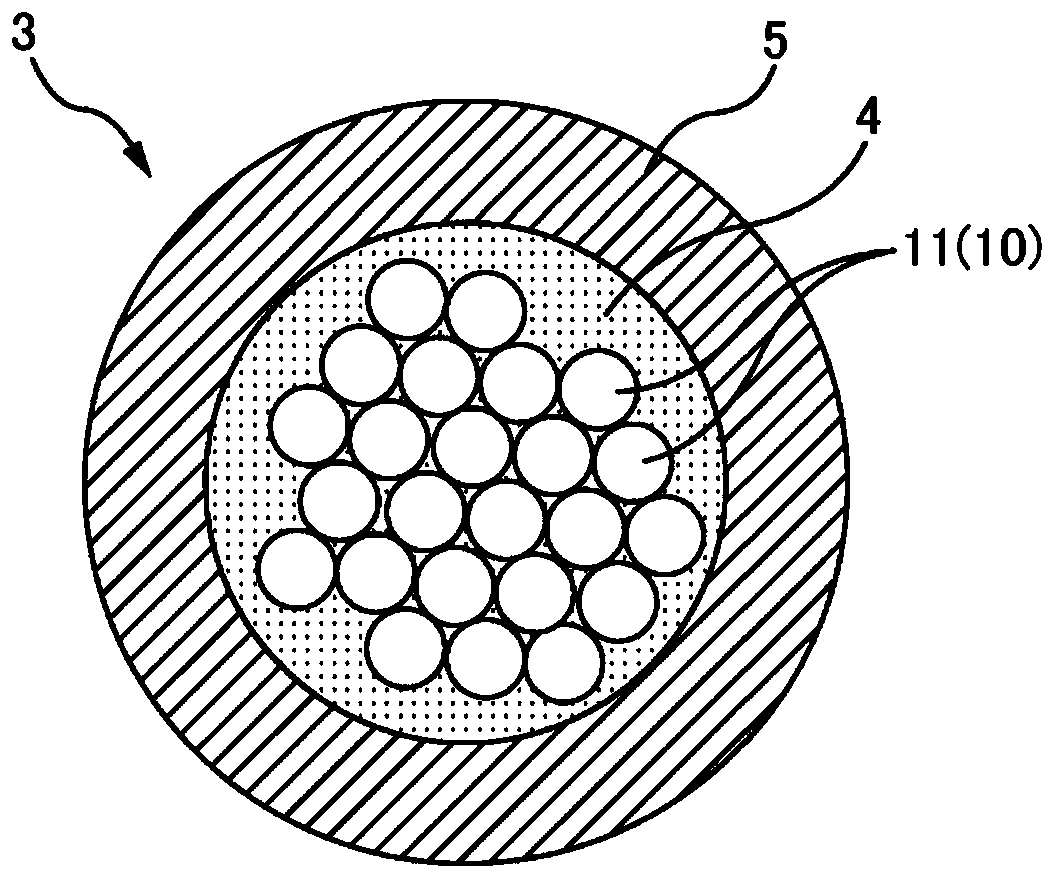

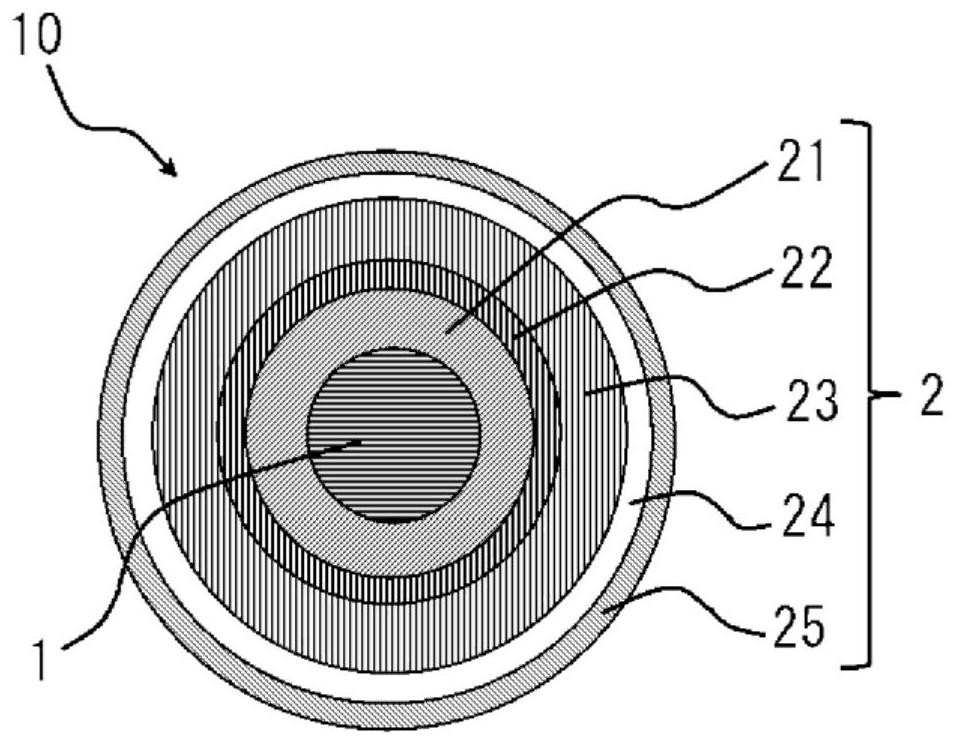

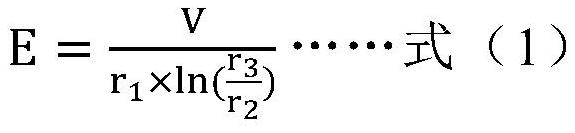

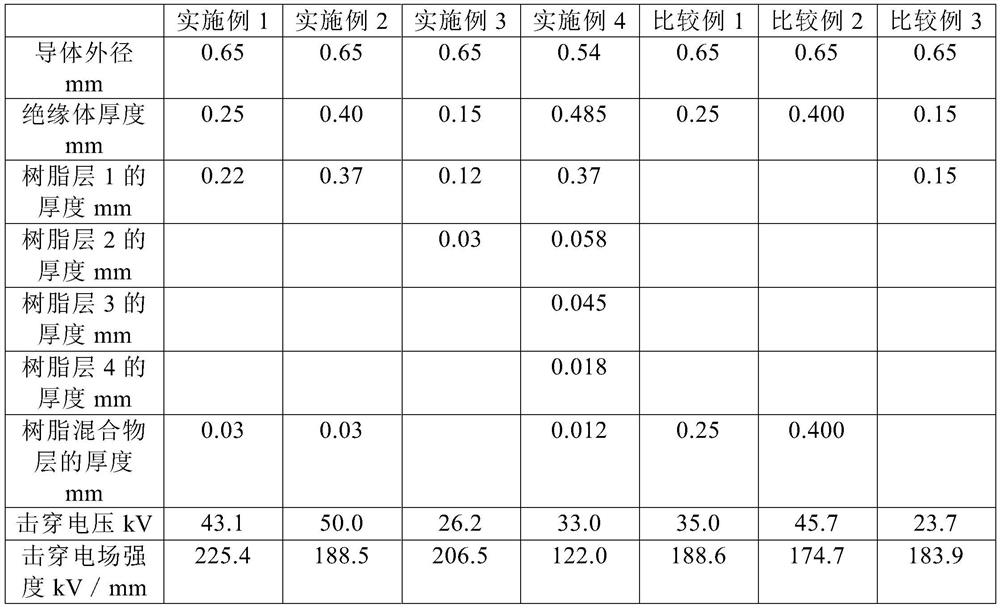

cable

ActiveCN111492445BImprove withstand voltage characteristicsAchieve finer diameterCable insulation constructionClimate change adaptationElectrical conductorRefractive index

It is an object of the present invention to provide an insulated cable which is suitable for sliding use while having improved withstand voltage characteristics required for reducing the diameter of the cable. The object of the present invention is achieved by providing an insulated cable characterized in that the insulated cable comprises: a conductor; and an insulator formed on the conductor by a plurality of resin layers, each of which contains the same kind of fluororesin, in the above-mentioned Among the resin layers, the difference between the refractive index of the resin layer with the largest refractive index and the resin layer with the smallest refractive index is 0.03 or less, and the layer thickness of the outermost resin layer of the above-mentioned insulator is 0.03 mm or less. The wall thickness unevenness (coefficient of variation CV) of the above-mentioned insulator in a cross section perpendicular to the longitudinal direction is 0.035 or less.

Owner:JUNKOSHA

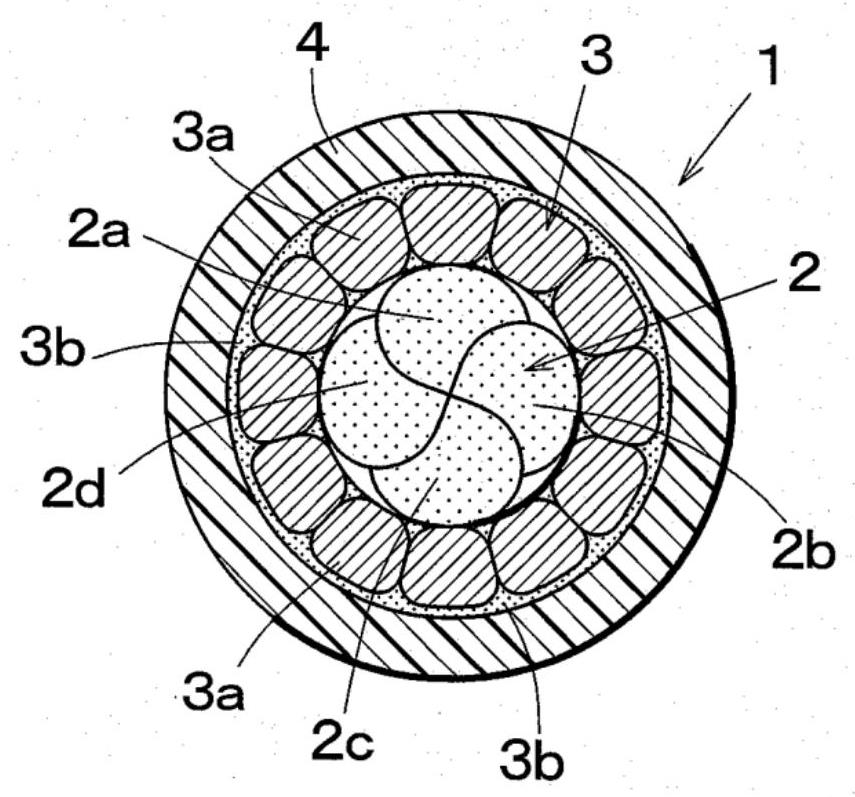

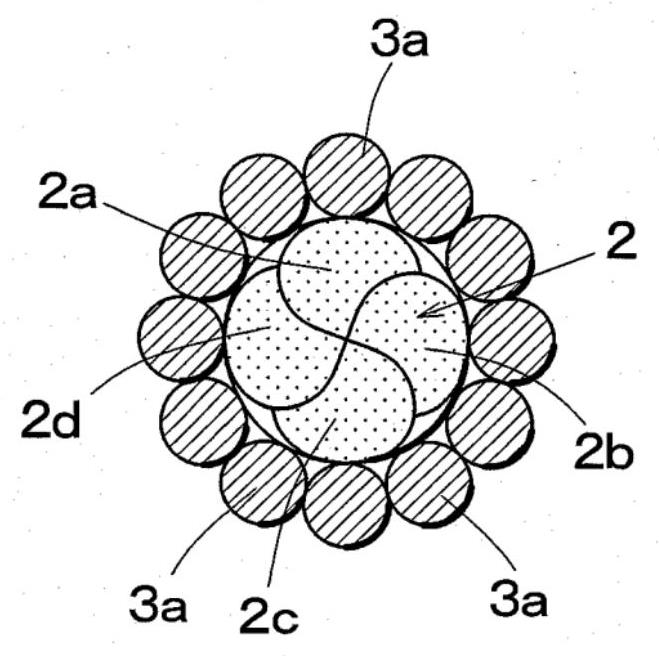

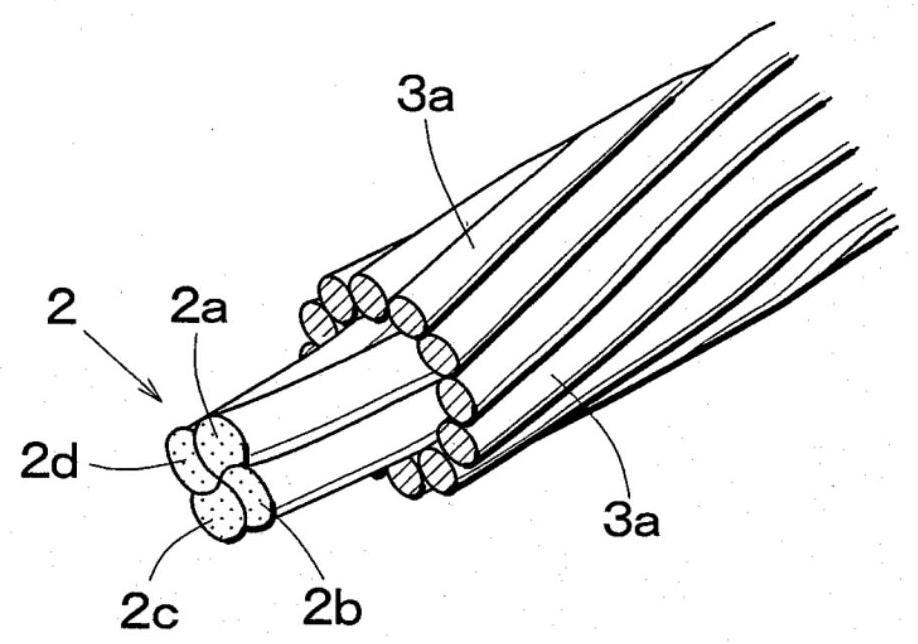

Composite electric wire and method for manufacturing composite electric wire

PendingCN114550978AImprove conductivityImprove plasticityConductive layers on insulating-supportsPlastic/resin/waxes insulatorsCopper wireCopper-wiring

The invention relates to a composite electric wire and a manufacturing method thereof. The problem to be solved by the present invention is to obtain a composite electric wire having strong conductivity and high plasticity. A conductive layer (3) is disposed around a central core wire (2), and an insulating coating layer (4) is provided around the conductive layer (3), thereby forming a composite electric wire having an outer diameter of about 500 mm. The core wire (2) is formed by twisting, for example, four center wires (2a-2d), and each center wire (2a-2d) is formed by twisting, for example, strands composed of 48 aramid fibers. The diameter of the strands is, for example, 12 [mu] m, and the diameter of the core wire (2) is about 200 [mu] m. As the conductive layer (3), 12 copper wires (3a), for example, having a diameter of 80 [mu] m, are closely wound around the core wire (2) in a spiral shape, and the peripheries of the copper wires (3a) are formed into a circle by tightening. Furthermore, the copper wires (3a) are covered by a tin layer (3b), which is a low-melting-point metal, with a thickness of several [mu] m, and the copper wires (3a) are adhered to each other by the tin layer (3b).

Owner:DELTA PLUS CO LTD

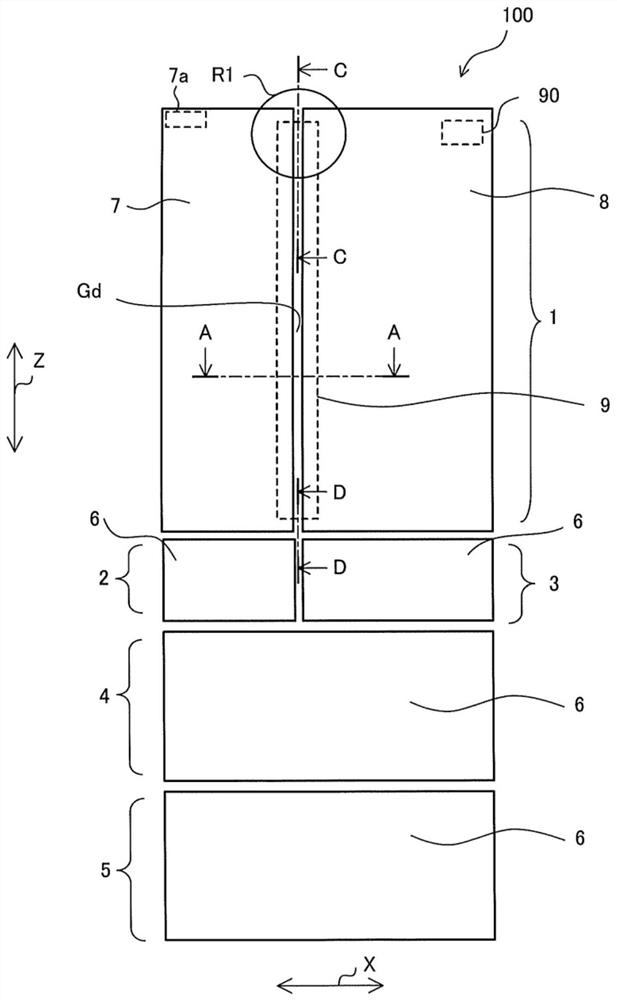

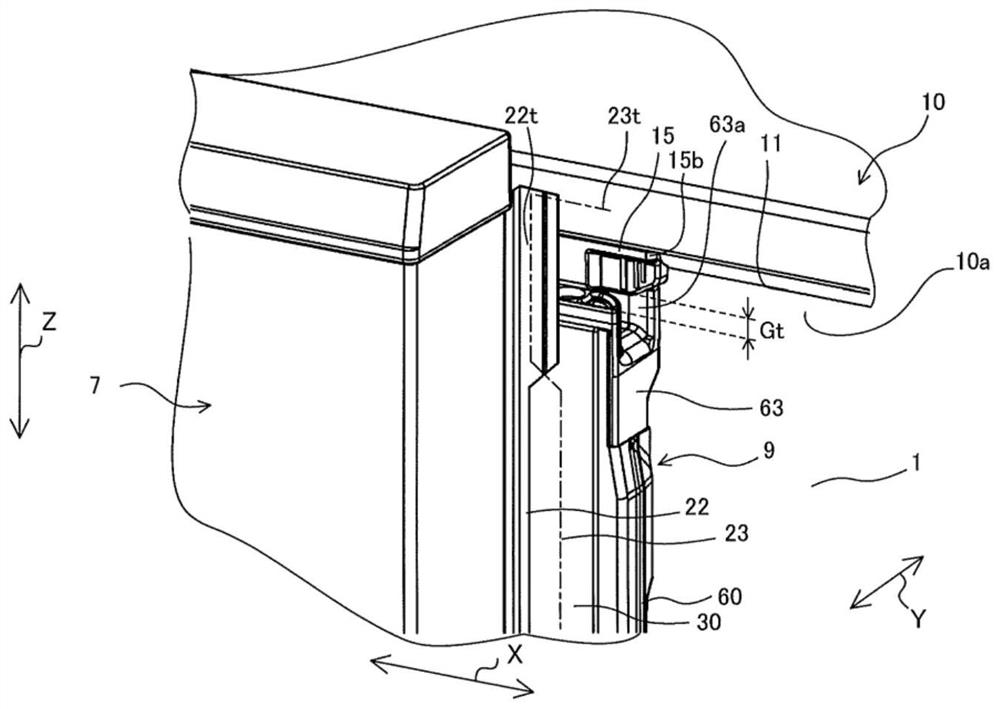

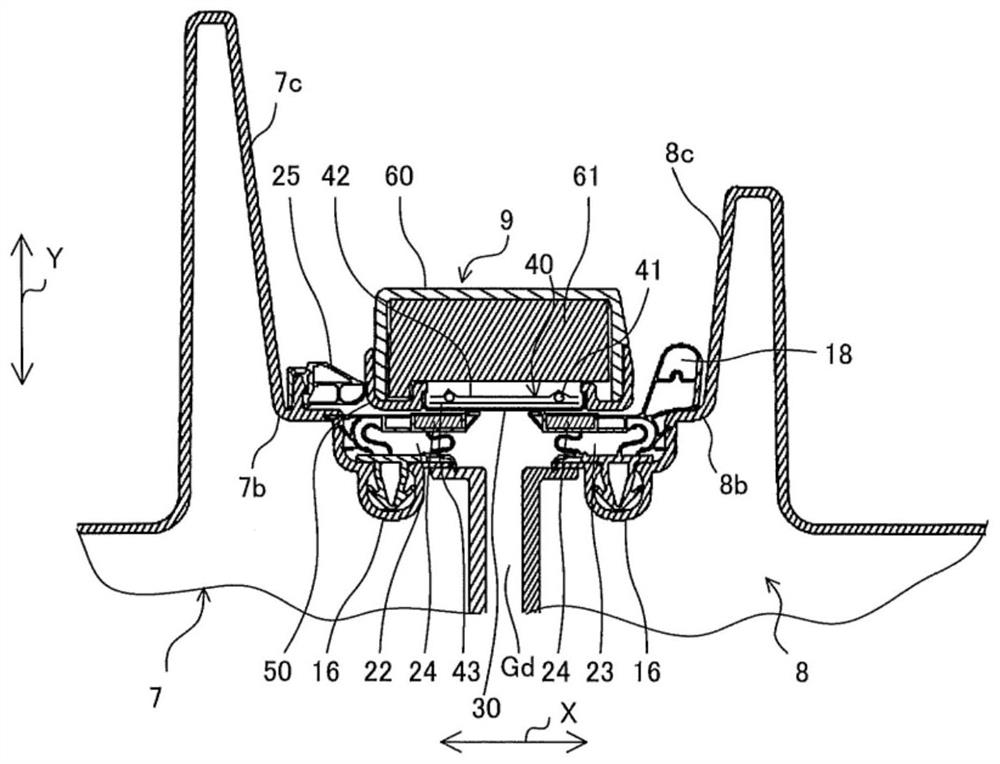

refrigeration refrigerator

ActiveCN111936807BIncrease freedomSuppresses increase in energization rateLighting and heating apparatusDefrostingIceboxEngineering

The refrigerating refrigerator of the present invention includes: a refrigerator main body having an opening and forming a storage room; two freely openable and closable doors arranged in parallel with the opening; The gap extends and closes the gap from the side of the storage room, and the partition plate has: a surface part, which is opposed to the door; a heater unit, which has a linear heater arranged to an end of the surface part, and the heater has: A heat generating part that generates heat by energization; and a basic insulating layer that covers the heat generating part, and two or more additional insulating layers are provided between the basic insulating layer and the surface member.

Owner:MITSUBISHI ELECTRIC CORP

Ultrasonic inspection system

PendingCN114145778APrevent image degradationAchieve finer diameterSurgeryEndoscopesCapacitanceCoaxial cable

The present invention provides an ultrasonic inspection system capable of suppressing image quality degradation of an ultrasonic image and capable of reducing the diameter of an ultrasonic endoscope. An ultrasonic inspection system is provided with: an ultrasonic transducer array in which a plurality of ultrasonic transducers are arranged; a cable connected to the plurality of ultrasonic transducers, the cable having: a non-coaxial cable including a first cable bundle comprising a plurality of signal lines and a plurality of ground lines, and a first shield layer covering the first cable bundle; and an outer sheath covering a second cable bundle composed of a plurality of non-coaxial cables. A memory that stores capacitance data indicating the capacitance of each signal line included in the first cable harness; and a processor that periodically corrects the transmission / reception sensitivity of each ultrasonic transducer on the basis of the capacitance data stored in the memory.

Owner:FUJIFILM CORP

Gas insulation switching device

InactiveCN101669260BAchieve finer diameterSimplify the routing structureBus-bar/wiring layoutsGas-insulated substationsEngineeringSwitchgear

In a multi-busbar system gas insulated switchgear, a power transmission / reception line unit (I) is constituted by providing a plurality of branch lead-out ports at regular intervals (interval H) along a vertical direction on the lateral side of a tank of a vertical-type circuit breaker, connecting a line-side device to the uppermost branch lead-out port, connecting the busbar-side devices to the lower branch lead-out ports, and arranging the line-side device to face the circuit breaker while placing multiple busbars therebetween. In a busbar link line unit (III), the tank length of a vertical-type circuit breaker is shorter than the tank length of the circuit breaker by the interval H, and an interval between a plurality of branch lead-out ports for busbar-side-device connection that are provided on the later side of the tank of the circuit breaker along a vertical direction is also the interval H.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com