Flow rate control valve for flow rate control device

A technology of flow control device and flow control valve, which is applied in the direction of valve device, valve operation/release device, diaphragm valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

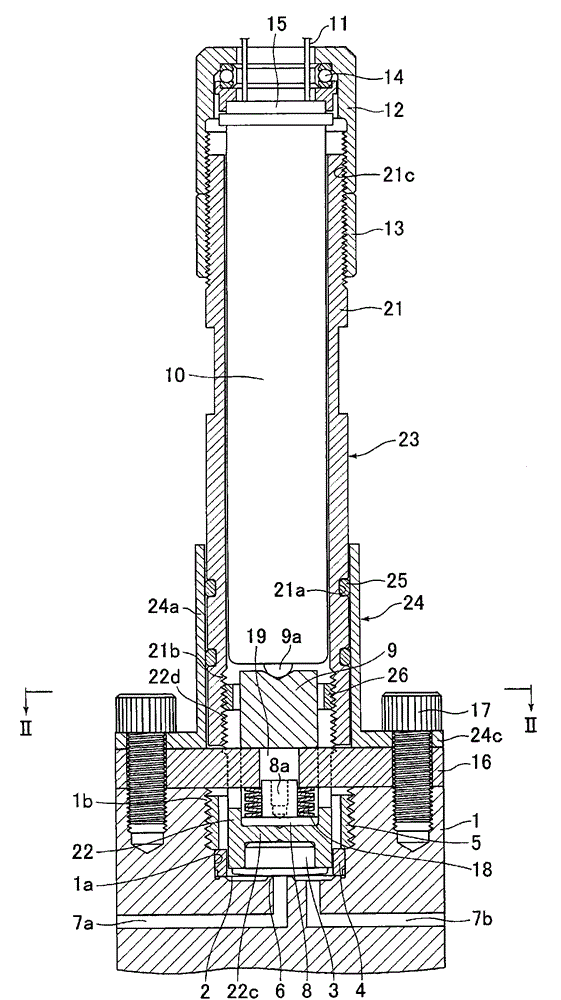

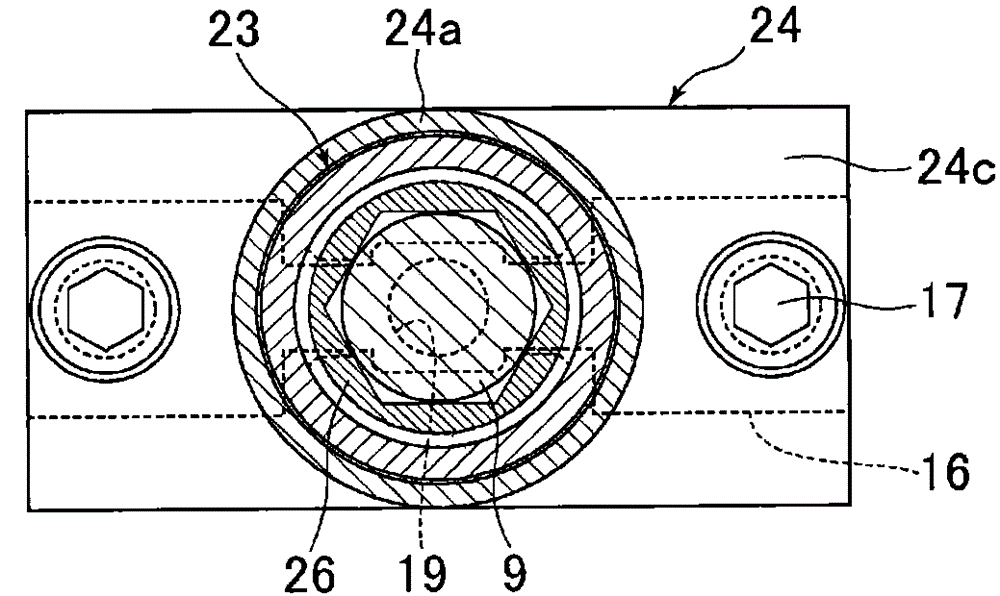

[0100] figure 1 and even Figure 8 It is a figure showing the first embodiment of the present invention, figure 1 It is a longitudinal sectional view of the normally closed piezoelectric element-driven metal diaphragm control valve according to the first embodiment of the present invention, figure 2 for figure 1 The II-II section outline diagram.

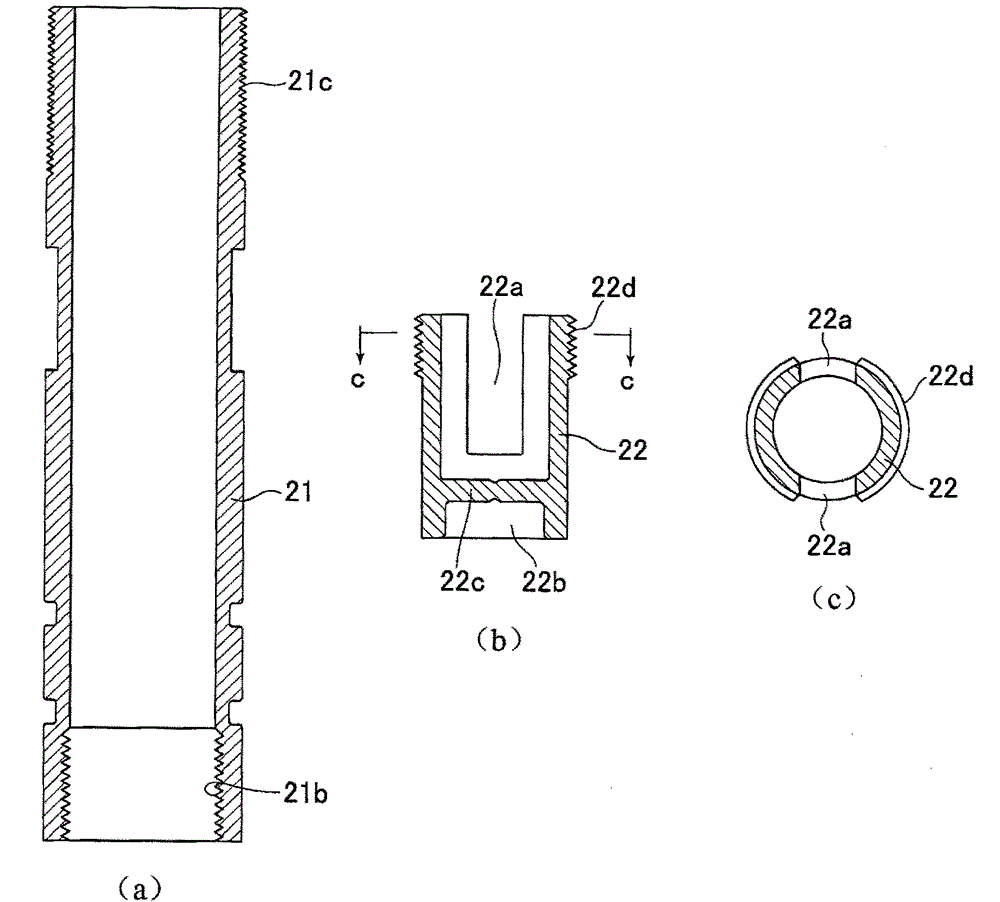

[0101] The control valve is composed of the following components: a valve main body 1 provided with a valve chamber hole 1a; a metal diaphragm valve body 2 arranged opposite to a valve seat 6 formed on the bottom surface of the valve chamber hole 1a; Insert the lower support cylinder 22 of the piezoelectric element 10 above the metal diaphragm valve body 2 of the hole 1a; insert the lower support cylinder 22 in the horizontal direction and fix it on the support stand 16 of the valve main body 1; insert it into the support The disc spring bearing platform 8 and the disc spring 18 between the platform 16 and the bottom wall 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com