Optical collimator

A technology of optical collimation and optical fiber, which is applied in the direction of coupling of optical waveguides to achieve the effect of reducing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

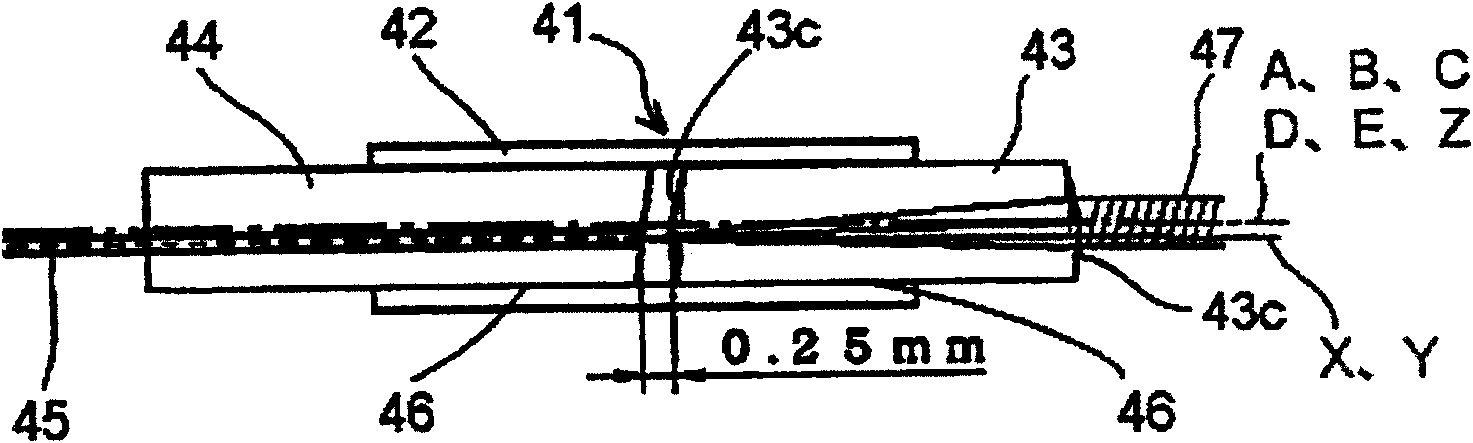

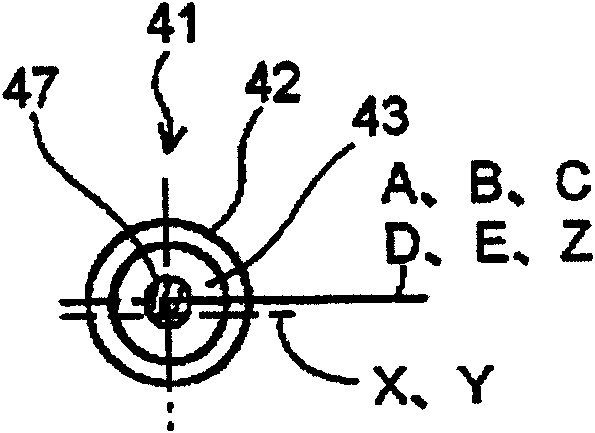

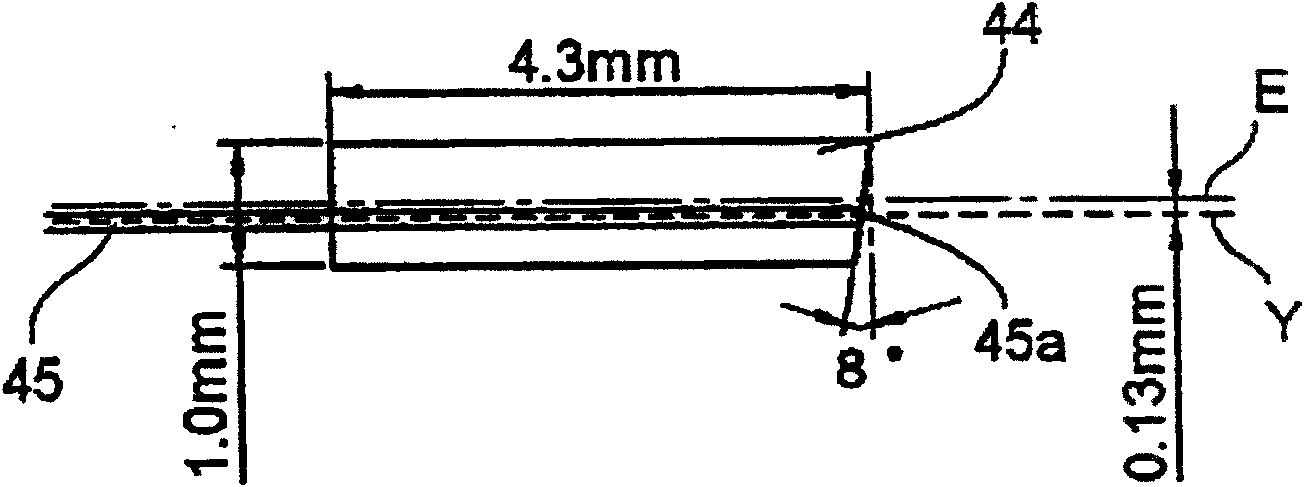

[0051] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0052] As shown in FIGS. 1 to 4 , the optical collimator 41 of this embodiment has a cylindrical sleeve 42 , a partially spherical lens 43 , and a capillary 44 . The sleeve 42 has an inner hole 42a at its center. The partially spherical lens 43 has a light-transmitting spherical surface 43c with substantially the same center of curvature at the two ends 43b of a cylindrical portion 43a made of glass with approximately uniform refractive index. When inserted into and fixed in the inner hole 42a of the sleeve 42, A position eccentric by a predetermined amount from the central axis B of the outer peripheral surface of the sleeve 42 becomes the optical axis X. The capillary 44 fixes the optical fiber 45 at a position eccentric by a predetermined amount with respect to the central axis B of the outer peripheral surface of the sleeve 42 when inserted and fixed into the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com