cable

A technology of insulated cables and coaxial cables, applied in cables, insulated cables, bendable cables, etc., can solve the problems of reducing withstand voltage characteristics, reducing mechanical strength of wear resistance, and not developing cables, etc., to achieve thin diameter The effects of chemicalization, improved withstand voltage characteristics, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

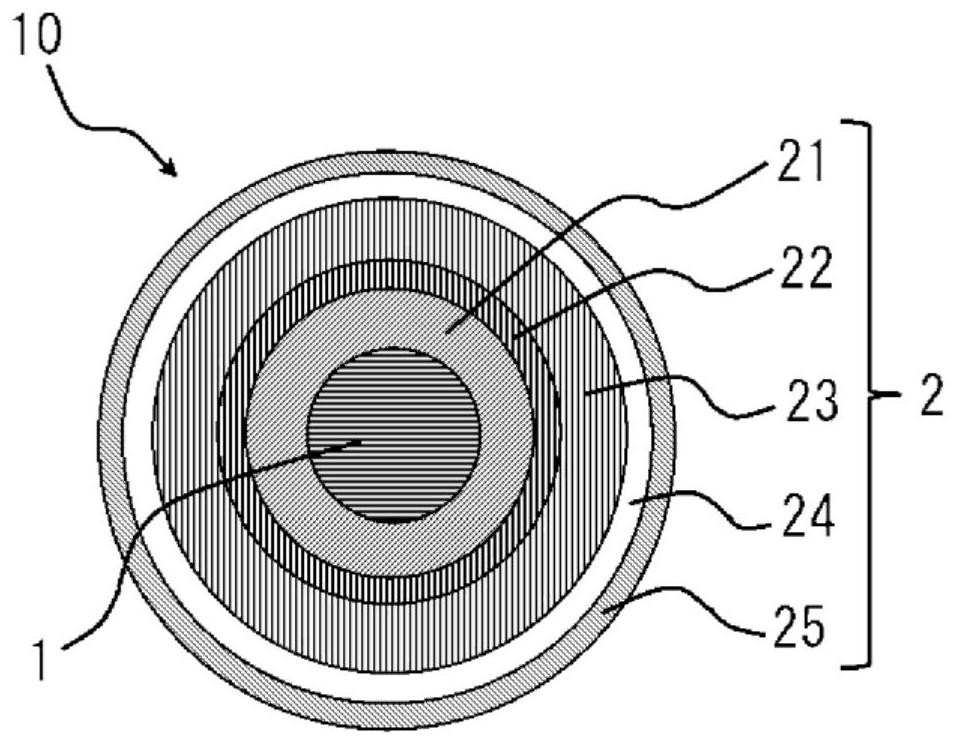

Image

Examples

Embodiment 1

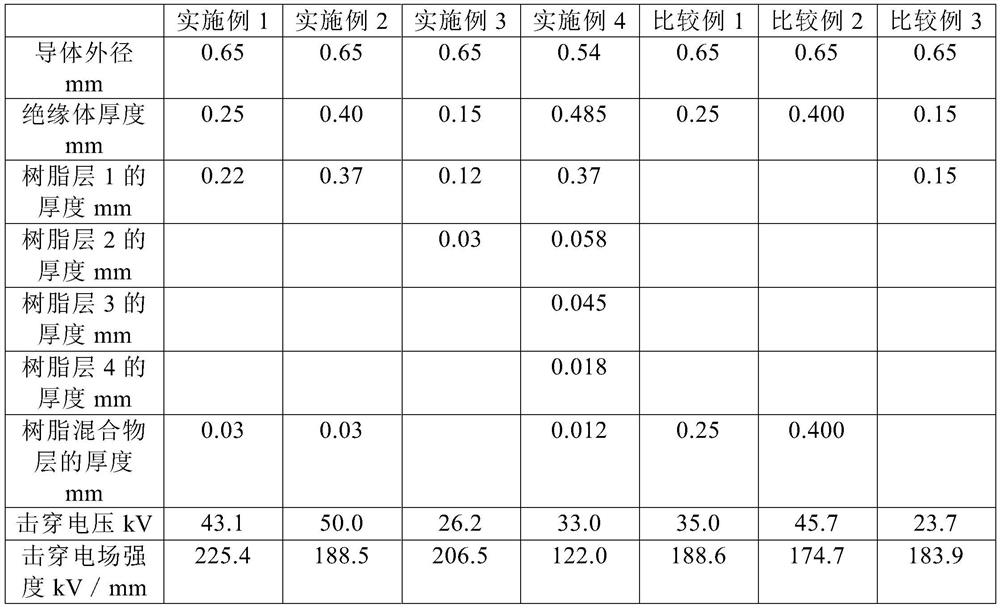

[0032] An annealed copper wire with a diameter of 0.65mm was used as the conductor. Ethylene tetrafluoroethylene (melt flow rate: 10g / 10min (American Society for Testing Materials-D3159 (297°C × 49N)) with a thickness of 0.22mm was extrusion-coated on the conductor by co-extrusion and 0.03mm mixed with white pigment. mm thickness of ethylene tetrafluoroethylene resin composition (melt flow rate: 10 g / 10 min) for use as an insulator with a wall thickness of 0.25 mm.

Embodiment 2

[0034] An annealed copper wire with a diameter of 0.65mm was used as the conductor. Ethylene tetrafluoroethylene (melt flow rate: 10g / 10min) of extrusion coating 0.37mm thickness and the ethylene tetrafluoroethylene resin composition (melt flow rate: 11g / 11g) of 0.03mm thickness mixed with white pigment on this conductor / 10min) to be used as an insulator with a wall thickness of 0.40mm.

Embodiment 3

[0036] An annealed copper wire with a diameter of 0.65mm was used as the conductor. Ethylene tetrafluoroethylene (melt flow rate: 11 g / 10 min) with a thickness of 0.12 mm and ethylene tetrafluoroethylene (melt flow rate: 11 g / 10 min) with a thickness of 0.03 mm were extrusion coated on the conductor by coextrusion, To be used as an insulator with a wall thickness of 0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com