Composite electric wire and method for manufacturing composite electric wire

A manufacturing method and electric wire technology, applied in the direction of cable/conductor manufacturing, conductive core parts, equipment for manufacturing conductive/semiconductive layers, etc., can solve the problems of manufacturing method and complex structure, and achieve easy manufacturing and plasticity Large, to achieve the effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

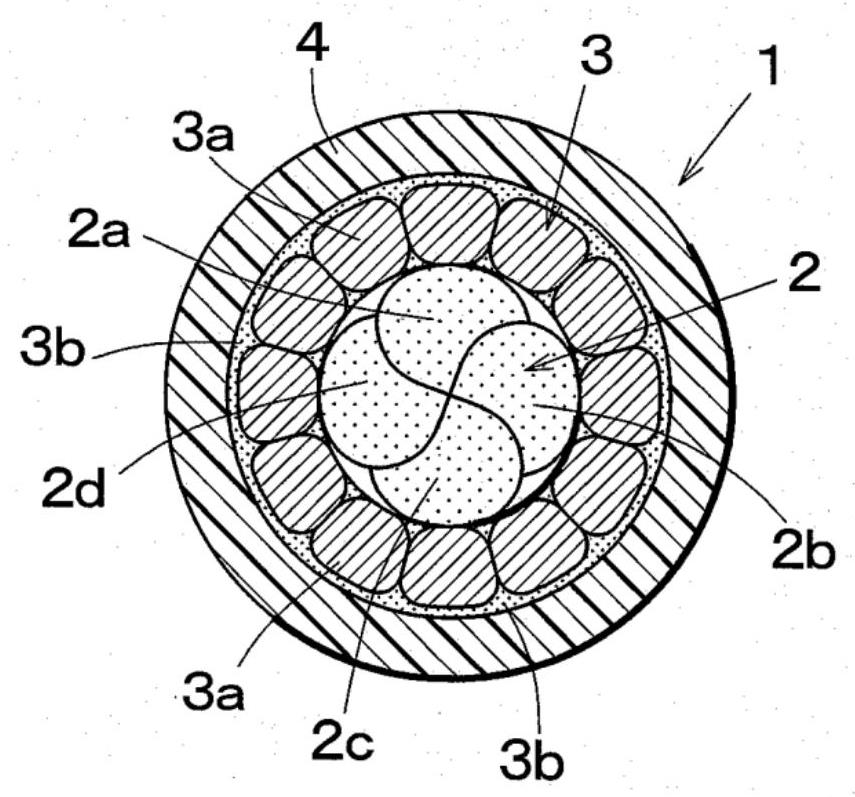

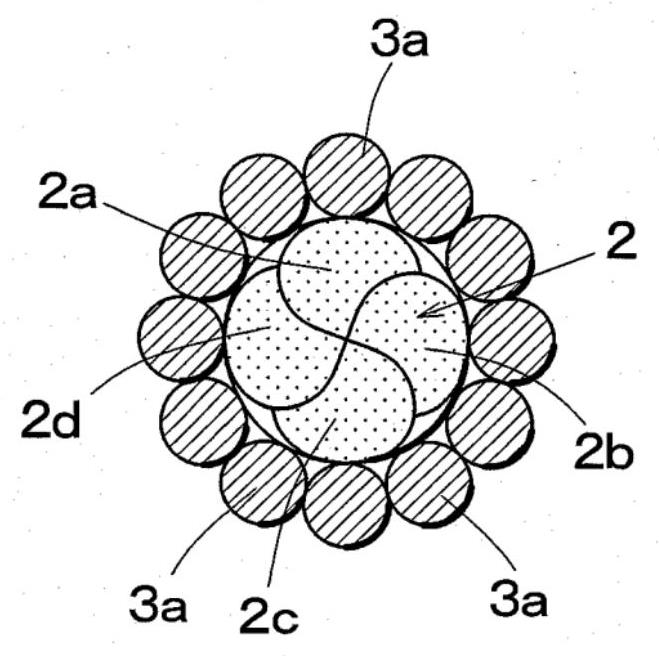

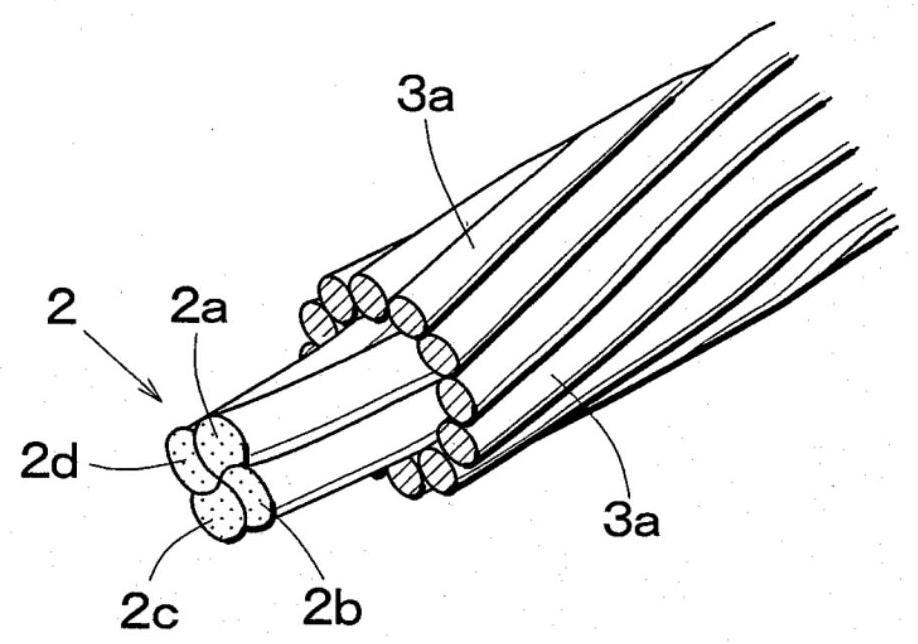

[0030] figure 1 It is a cross-sectional view of the composite electric wire 1 of Example 1. A conductive layer 3 composed of a copper wire 3 a and a tin layer 3 b is arranged around the core wire 2 , and an insulating coating layer 4 is further arranged around the conductive layer 3 , which has flexibility as a whole.

[0031] The core wire 2 is formed by twisting, for example, four middle wires 2a to 2d, and each of the middle wires 2a to 2d is formed by twisting a polymer strand made of a synthetic resin material such as 48 aramid fibers. The diameter of these strands is, for example, 12 μm, and the diameter of the core wire 2 is about 200 μm. In addition, the aramid fiber has the characteristics of being light in weight, high in strength and high in flexibility, and not conductive.

[0032] The conductive layer 3 includes: a conductive metal wire with a high melting point, such as a copper wire (Cu: melting point 1085°C) 3a; and a low melting point metal, which is a metal...

Embodiment 2

[0047] Figure 8 It is a cross-sectional view of the composite electric wire 1' of Example 2. In the composite electric wire 1 ′, a coating layer 5 is provided around the core wire 2 , a conductive layer 3 composed of a copper wire 3 a and a tin layer 3 b is arranged outside the coating layer 5 , and an insulating layer is provided around the conductive layer 3 . cladding 4.

[0048] The structure of the core wire 2 is the same as that of Example 1, but the coating layer 5 is provided around the core wire 2. The coating layer 5 is made of, for example, a polyester resin and has a thickness of several μm. In addition, the conductive layer 3 and the insulating coating layer 4 have the same structure as that of the first embodiment.

[0049] Figure 9It is an explanatory drawing of the manufacturing process of this composite electric wire 1'. Including: the coating step E, coating the coating layer 5 around the core wire 2; the metal wire winding step A, then winding the copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com