Gas insulation switching device

A technology for gas insulated switches and circuit breakers, which is applied in the direction of switchgear, switchgear setting, gas insulated substation, etc., which can solve the problems of increased manufacturing cost and longer wiring path, and achieve shortened length, reduced installation space, and simplified The effect of trace structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

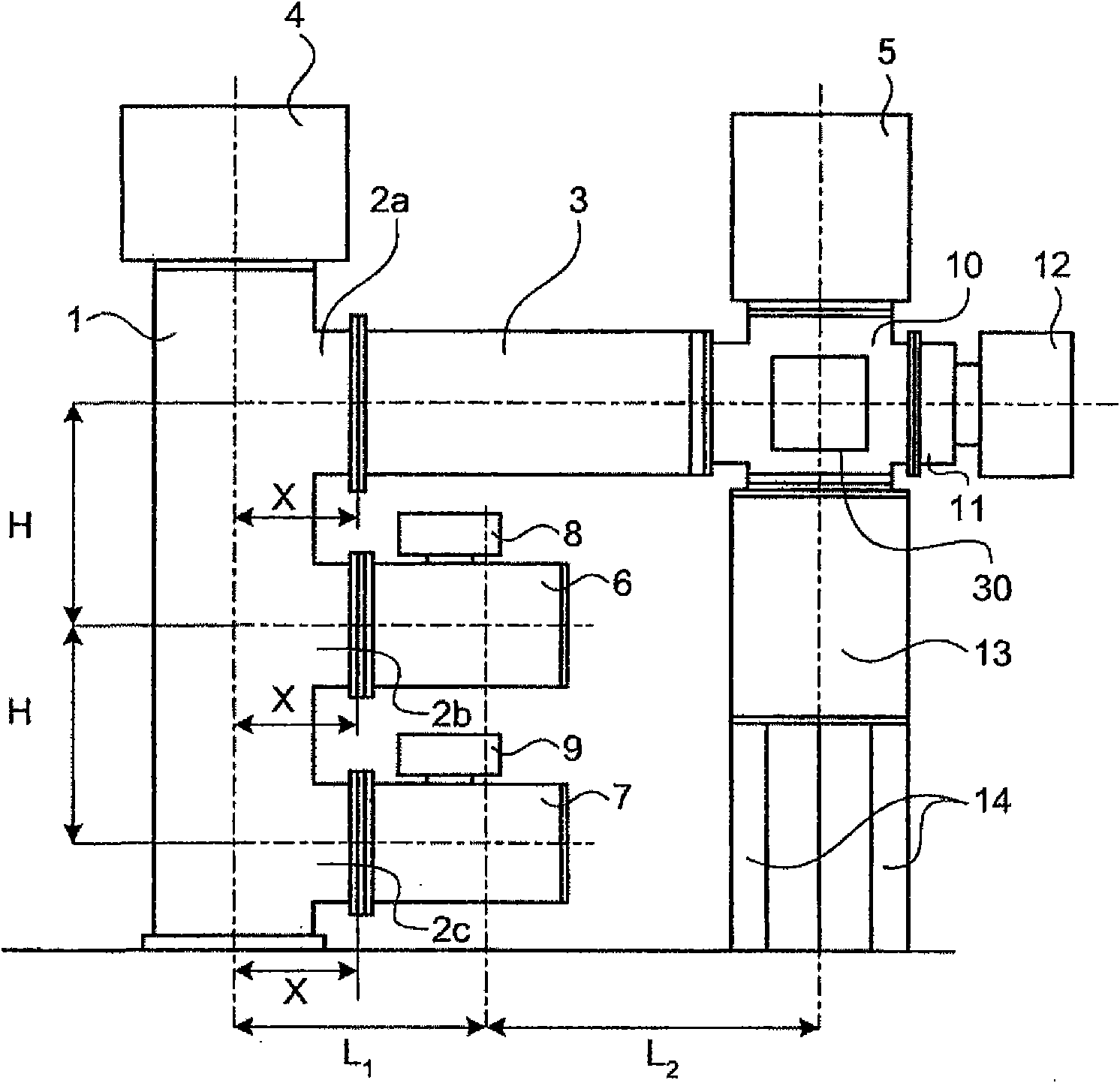

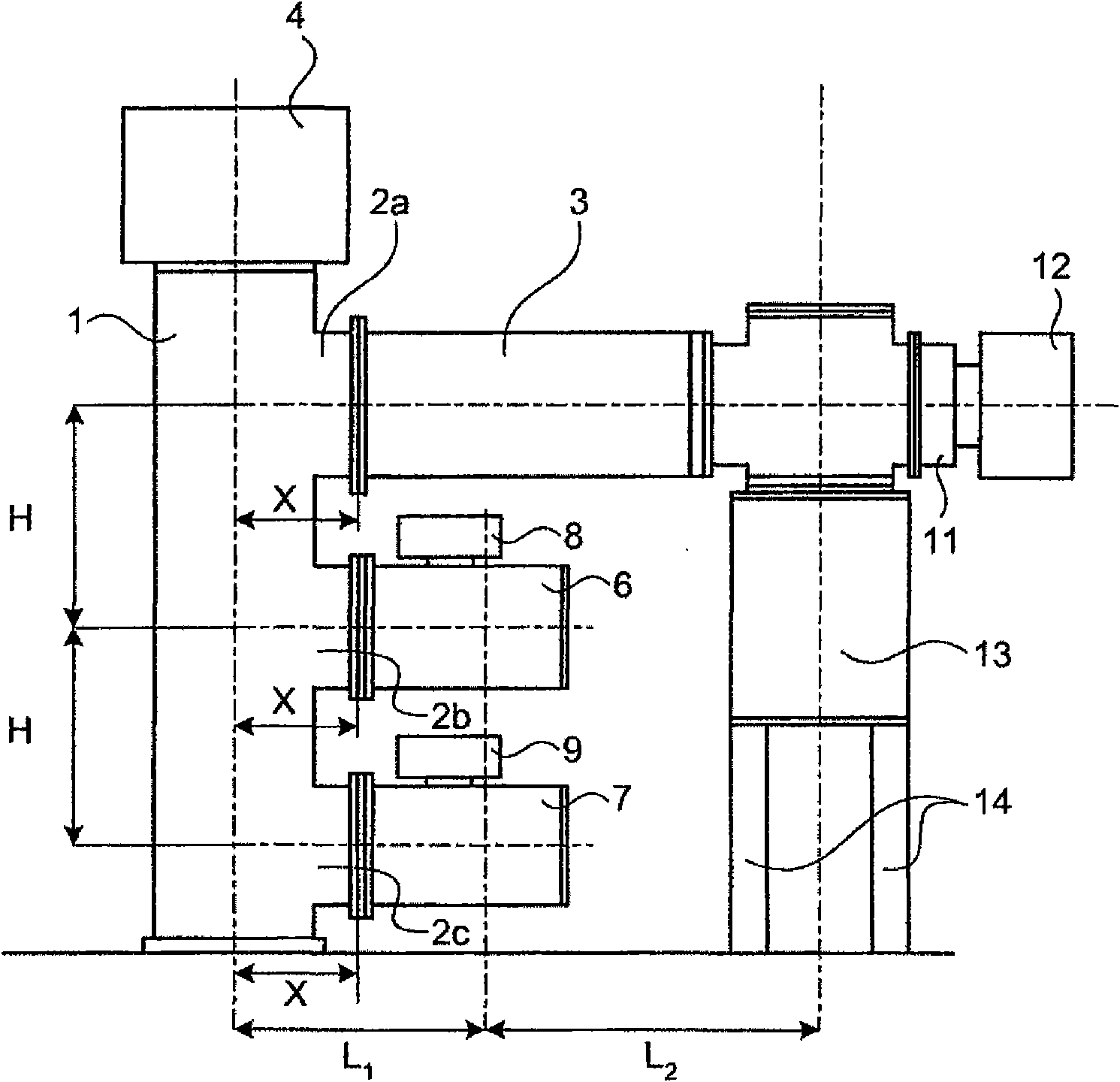

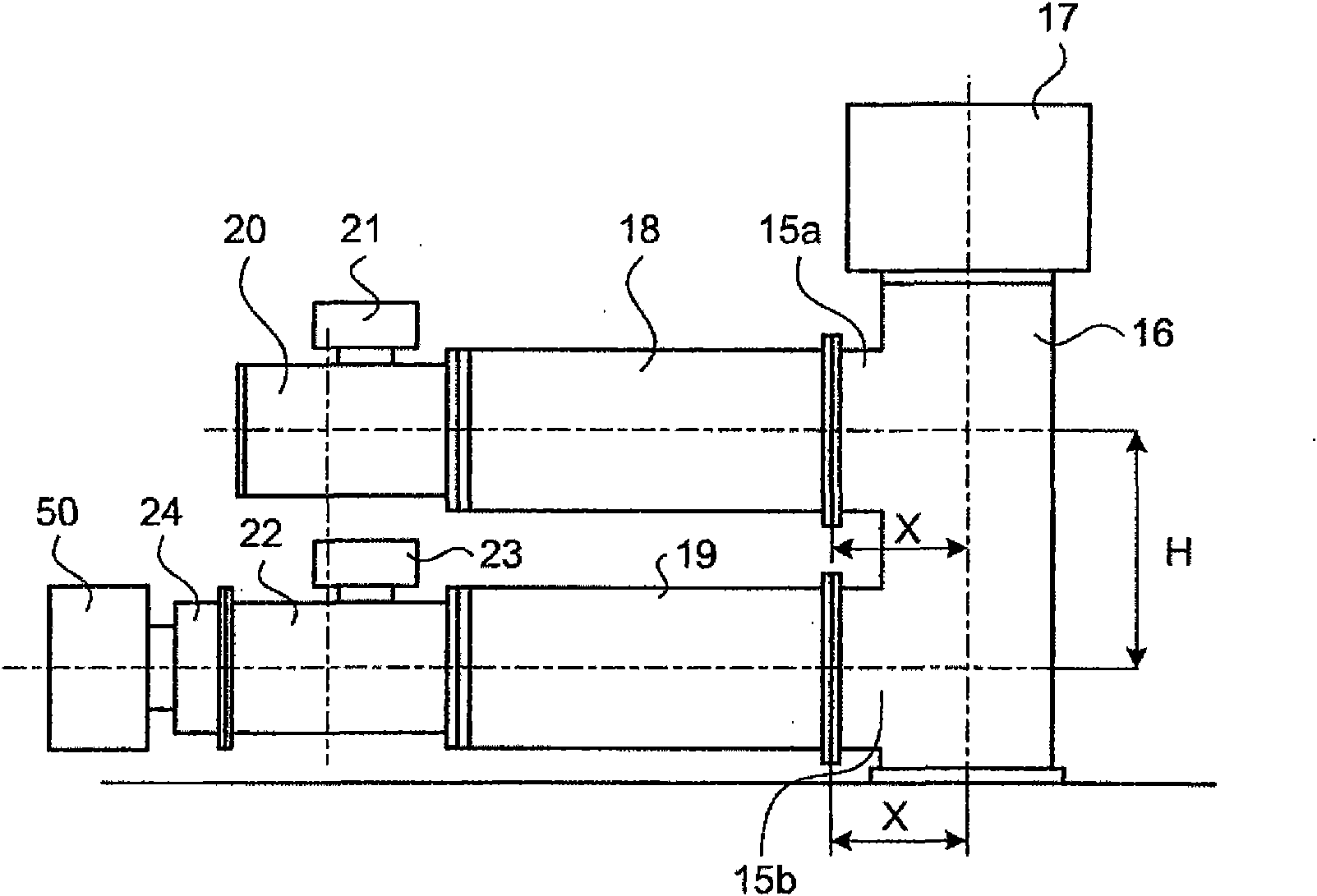

[0050] figure 1 It is a cross-sectional view showing the structure of the gas insulated switchgear according to the present embodiment, and is a view showing a unit for power transmission and reception lines. figure 2 It is a figure which shows the unit for transformer wires which is another form of the unit for power transmission and reception wires in this embodiment. in addition, image 3 It is a cross-sectional view showing the structure of the gas insulated switchgear according to the present embodiment, and is a view showing a unit for bus-bar connecting wires.

[0051] Such as figure 1 As shown, a circuit breaker 1 having a circuit breaker is installed inside a cylindrical container filled with an insulating gas. The circuit breaker 1 is a circuit breaker in which the central axis direction of the container is vertically perpendicular to the installation surface. An operating device 4 for operating the circuit breaker 1 is arranged on the upper part of the container...

Embodiment approach 2

[0082] In Embodiment 1, the case of the multi-bus system was described, but in this embodiment, the case of the single-bus system will be described. Figure 7 It is a cross-sectional view showing the structure of the gas insulated switchgear according to the present embodiment, and is a view showing a unit for power transmission and reception lines. Figure 8 It is a figure which shows the unit for transformer wires which is another form of the unit for power transmission and reception wires in this embodiment.

[0083] Such as Figure 7 As shown, a circuit breaker 31 having a disconnection portion is provided inside a cylindrical container filled with an insulating gas. The circuit breaker 31 is a circuit breaker whose central axis direction of the container is vertically perpendicular to the installation surface. The circuit breaker 31 is disposed on the supporting frame 45 . In addition, on the upper part of the container of the circuit breaker 31, an operating device 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com