Rotatable air shot jet pipe

A spray tube and air cannon technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of small spray area, the spray area can only be limited to the position directly below the spray port, and the low utilization rate of the air cannon, so as to improve Use efficiency, effect of increasing spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

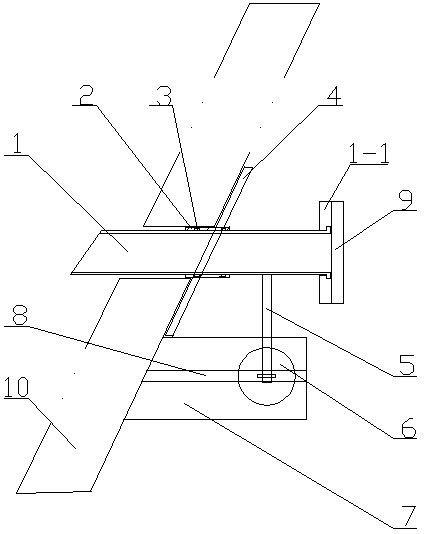

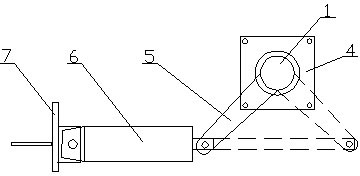

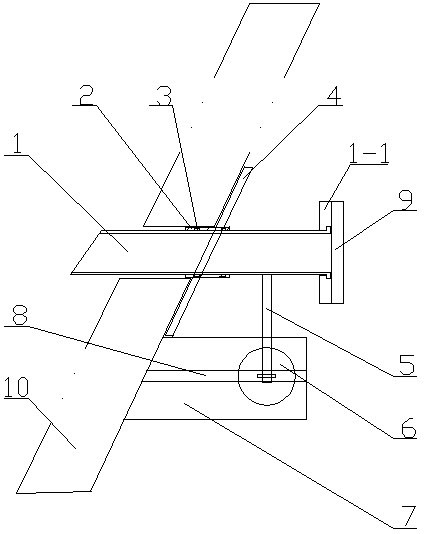

[0012] Such as figure 1 , figure 2 As shown, a rotatable air cannon spray pipe includes a spray pipe body 1, which is connected to the spray pipe rotating mechanism 8, the front end of the spray pipe body 1 is provided with a bevel, and the rear end of the spray pipe body 1 is provided with a movable method. The blue plate 1-1, the movable flange 1-1 are fixedly connected with the air cannon outlet pipe 9; the injection pipe body 1 is provided with a sealing sleeve 2, and a sealing ring 3 is arranged between the sealing sleeve 2 and the injection pipe body 1 to seal The sleeve 2 is fixed on the first fixing plate 4 , and the first fixing plate 4 is fixedly connected with the silo wall 10 . The spray pipe rotation mechanism 8 includes a rotary push rod 5 connected with the spray pipe body 1, and the rotary push rod 5 is connected with the cylinder 6, and the cylinder 6 is arranged below the spray pipe body 1 and vertically arranged with the spray pipe body 1; the cylinder 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com