Concrete production yard dust fall spraying system

A spray system and concrete technology, applied in clay preparation devices, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of different heights, different sizes of the dust, and poor dust reduction effect in the places where the dust is concentrated. The effect of spraying area, increasing spraying angle and reducing spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings.

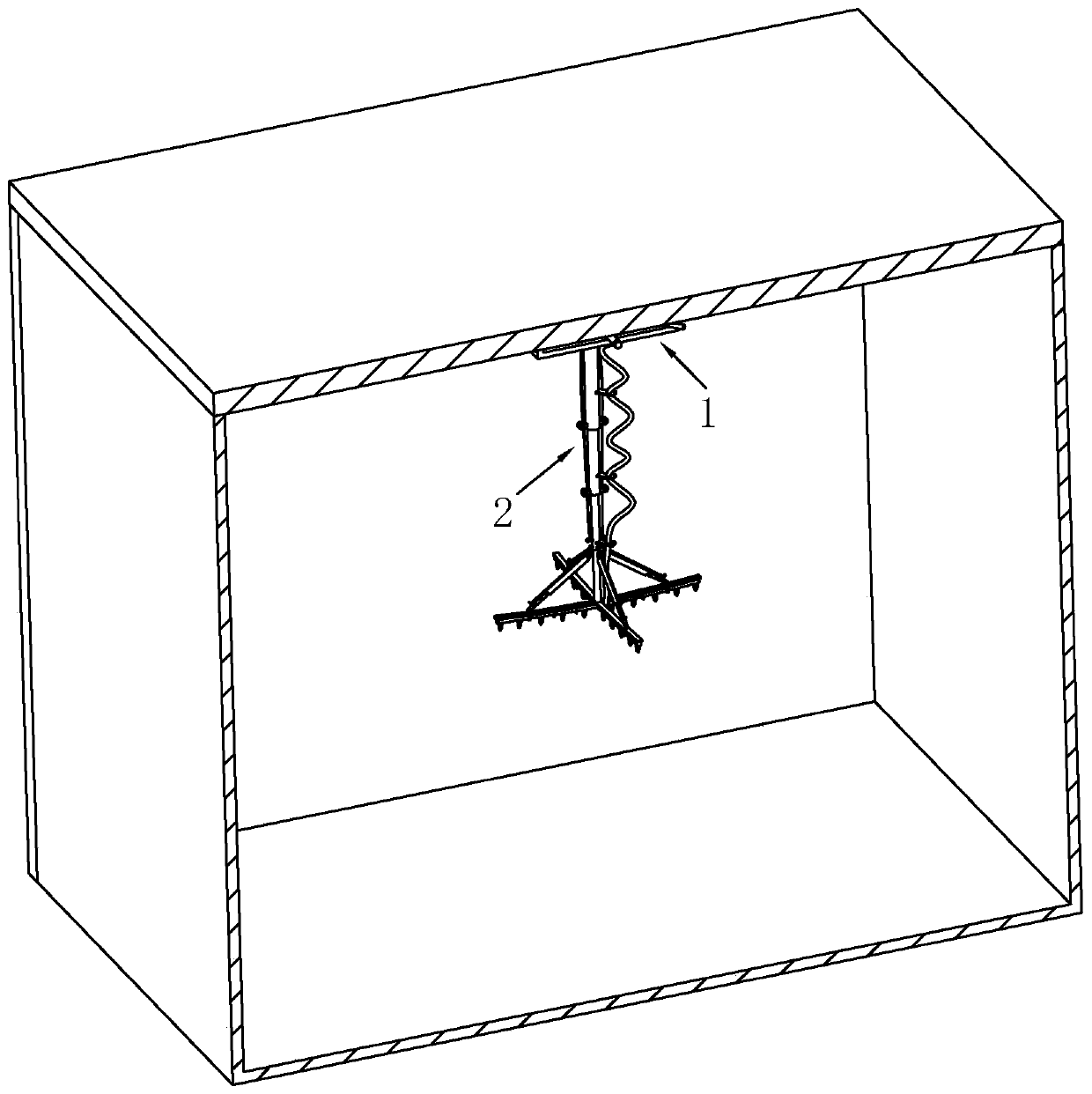

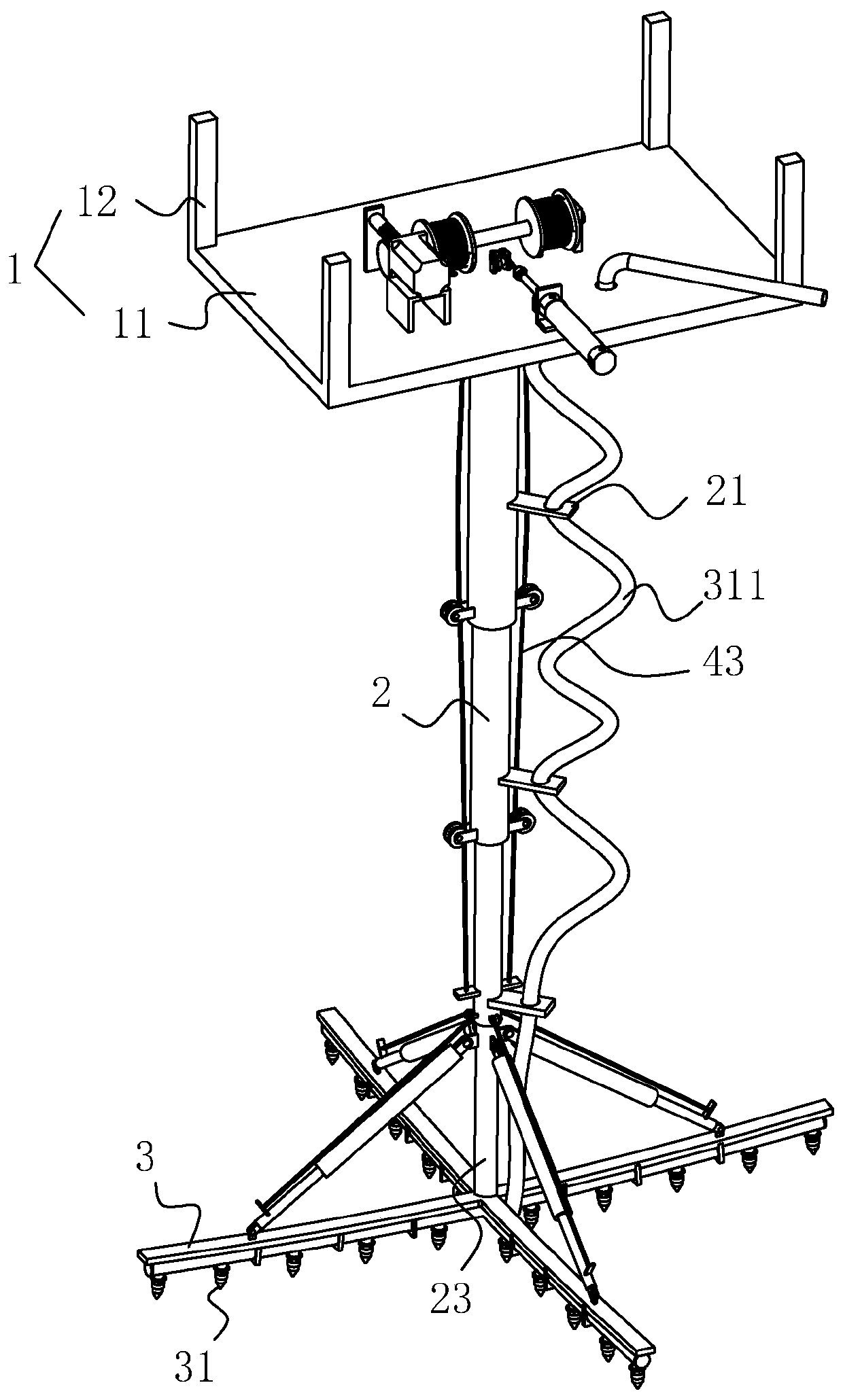

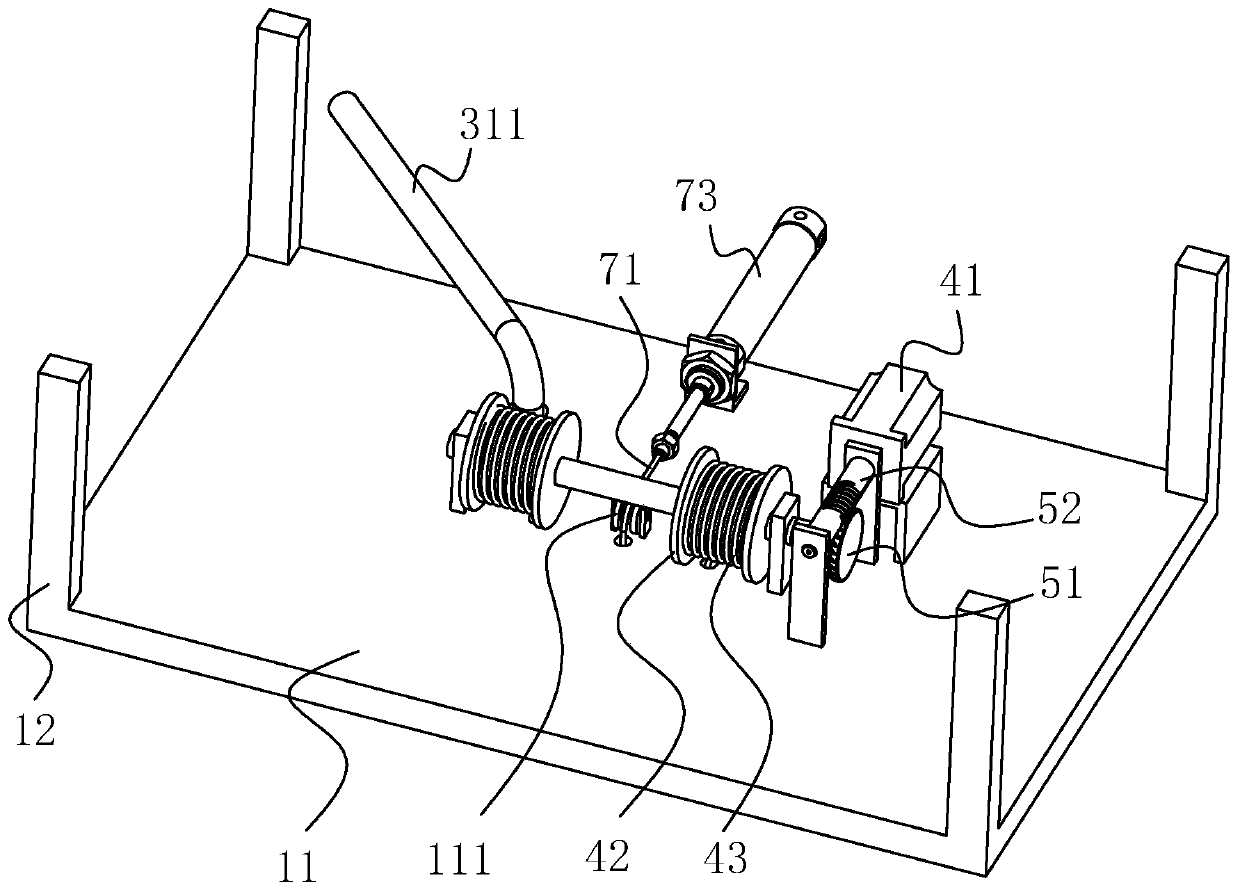

[0036] like figure 1 , 2 As shown, a dust suppression spraying system for a concrete production material yard includes a mounting frame 1 and a plurality of booms 2 that are sleeved layer by layer. The mounting frame 1 is fixedly arranged in the factory building. The mounting frame 1 includes a mounting plate 11 and a mounting rod 12. The mounting plate 11 is fixed on the bottom wall of the mounting rod 12. The mounting rod 12 is fixed on the steel beam at the top of the factory building, and is fixed by bolts or welding. .

[0037] like figure 2 As shown, the jib 2 is vertically arranged, and the uppermost jib 2 is fixed on the mounting plate 11. In this embodiment, the jib 2 is made of a hollow steel pipe. In other embodiments, a plastic pipe with sufficient strength can also be used. to make. The lowermost boom 2 is fixedly provided with a support rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com