a straight jet nozzle

A technology of nozzles and oil injection holes, applied in the field of direct injection nozzles, which can solve the problems of small spray angle, poor atomization effect, and simplicity, and achieve the effects of improving performance, increasing spray angle, and improving atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

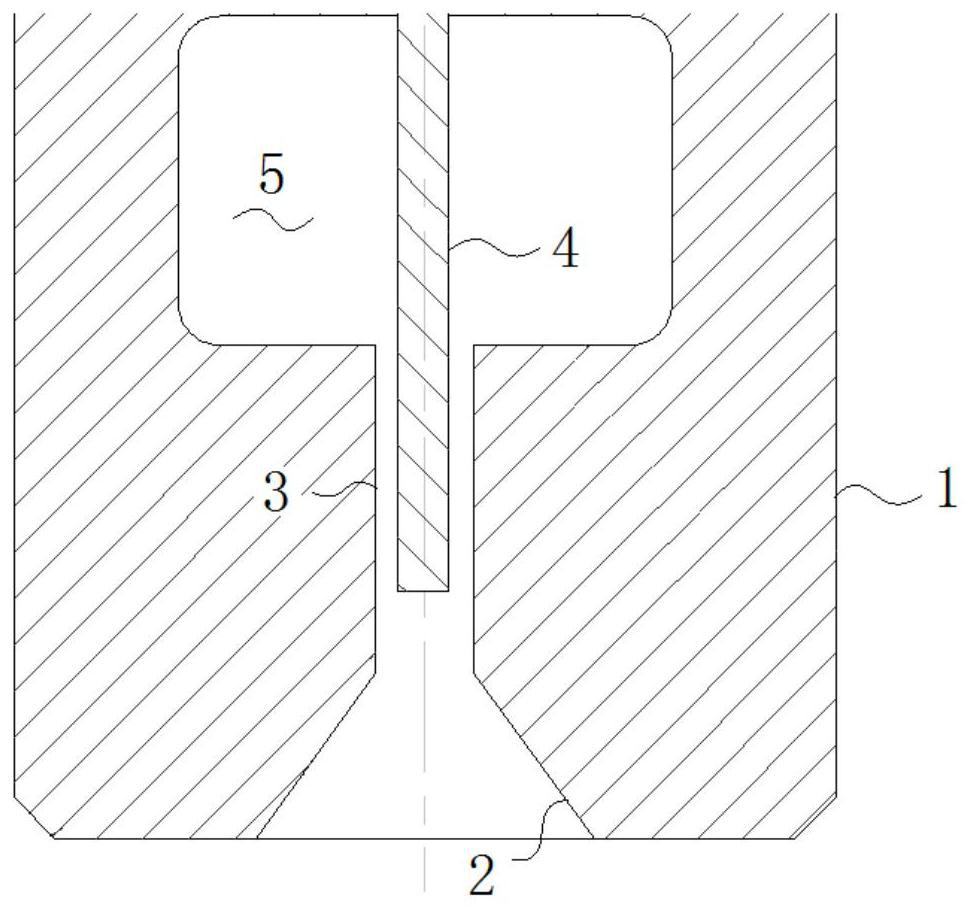

[0018] This application mainly aims at the problems of small spray cone angle and poor atomization effect of the direct injection nozzle used in the compact structure of the afterburner, multi-point injection combustion chamber and ram combustion chamber, and proposes a new direct injection nozzle. It can effectively improve the shortcomings of traditional direct injection nozzles and effectively improve the performance of the combustion chamber.

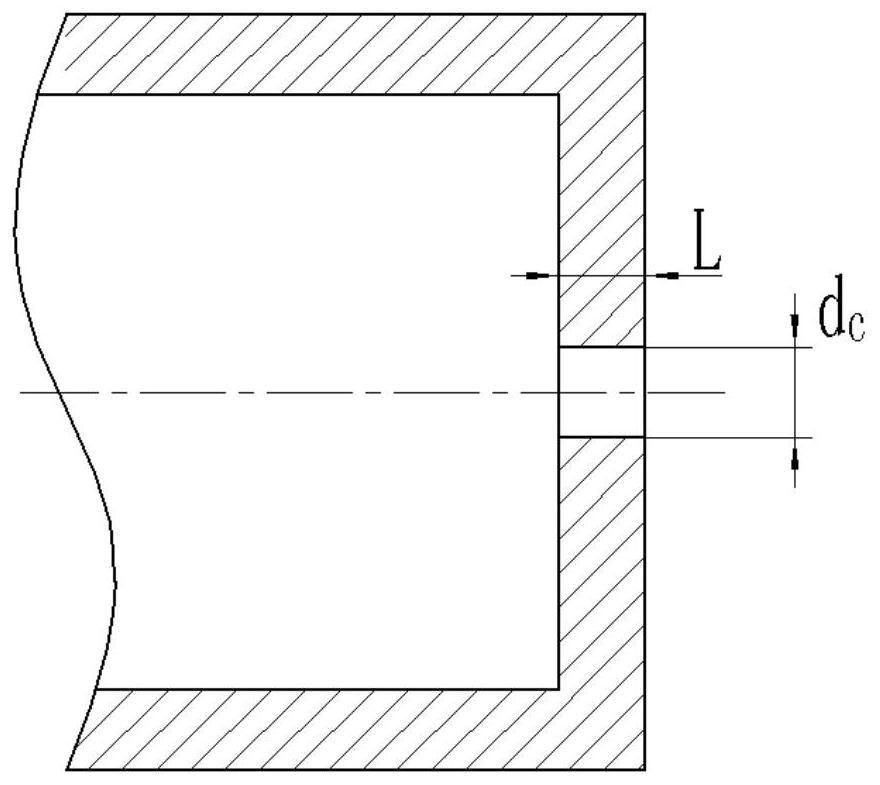

[0019] The present application is the same as the traditional direct injection nozzle, but still adopts pressure atomization, and the liquid fuel is sprayed out at a certain angle after being sprayed out through the oil injection hole 3, and is interacted with air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com