Environment-friendly sprinkling equipment and method for dust fall in building engineering construction

A technology of construction engineering and sprinkler equipment, which is applied in the field of construction engineering and can solve problems such as the inability to quickly clean up the dust and sediment at the sprinkling nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

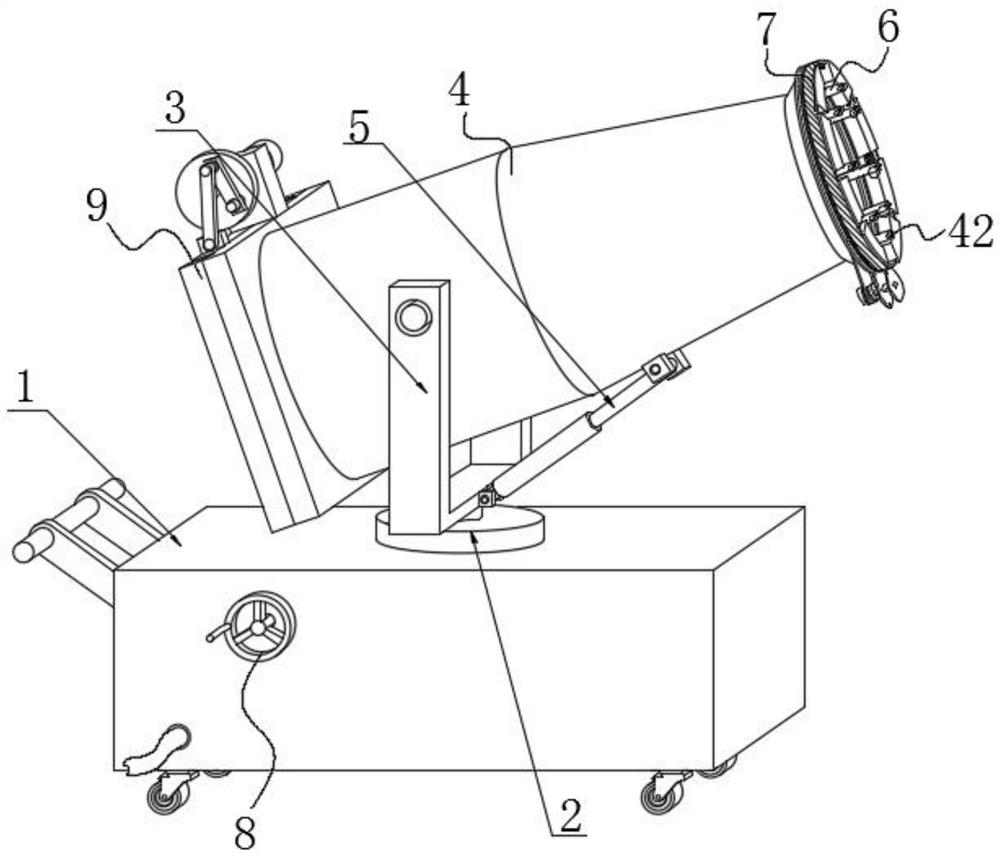

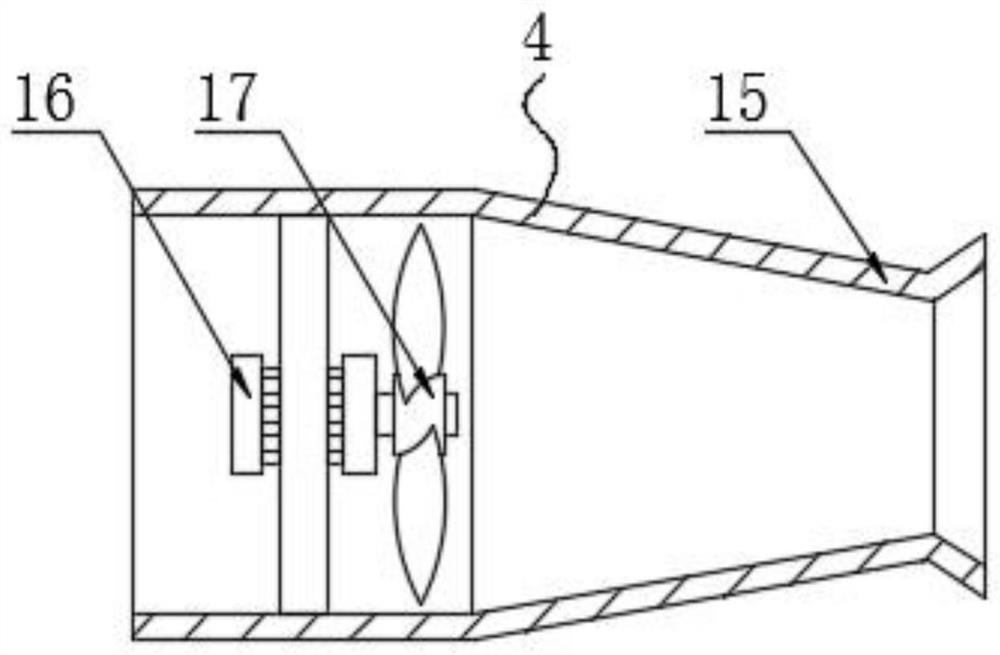

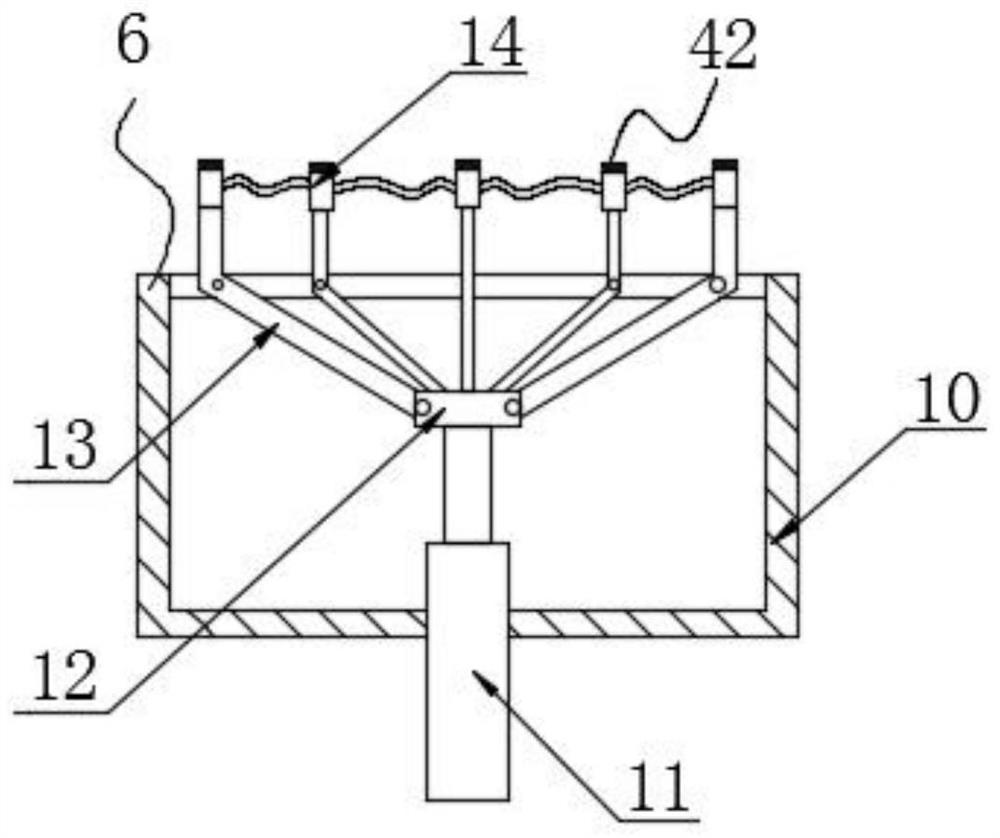

[0038] An environmentally friendly building construction with dust suppression sprinkler apparatus comprising a cartridge housing;

[0039] As a preferred embodiment, the housing is electrically connected to the top of the cartridge 1 is fixedly connected with a first motor 2, a first motor model 2 is SL57S2, a first motor 2 and a rechargeable battery (not shown), and by controlling switching control, the top of the output shaft of the first motor 2 is fixedly connected with a turret 3, the inner surface of the turret 3 is rotated via a shaft connected to hair mechanism 4, the front side of the turret plate 3 is rotated by a horizontal rotary shaft connected to a first telescoping rod 5, the extendable rod 5 of the first model 111, a first extendable rod 5 is electrically connected to the external power supply, and by controlling the switching control of the first telescopic jack lever 5 one end of the outer hair mechanism 4 is rotatably connected by a shaft, hair internal mechani...

Embodiment 2

[0041] The present embodiment as a modified example of the embodiment, an environmentally friendly building construction with dust suppression sprinkler apparatus comprising a cartridge housing;

[0042] As a preferred embodiment, the housing is electrically connected to the top of the cartridge 1 is fixedly connected with a first motor 2, a first motor model 2 is SL57S2, a first motor 2 and a rechargeable battery (not shown), and by controlling switching control, the top of the output shaft of the first motor 2 is fixedly connected with a turret 3, the inner surface of the turret 3 is rotated via a shaft connected to hair mechanism 4, the front side of the turret plate 3 is rotated by a horizontal rotary shaft connected to a first telescoping rod 5, the extendable rod 5 of the first model 111, a first extendable rod 5 is electrically connected to the external power supply, and by controlling the switching control of the first telescopic jack lever 5 one end of the outer hair mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com