Method for manufacturing cylindrical shaped knitted fabric

A technology of knitted fabrics and needle beds, which is applied in the field of cylindrical formed knitted fabrics, which can solve the problems of wrinkling or drafting, wearing comfort of knitted fabrics, and adverse effects on appearance, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

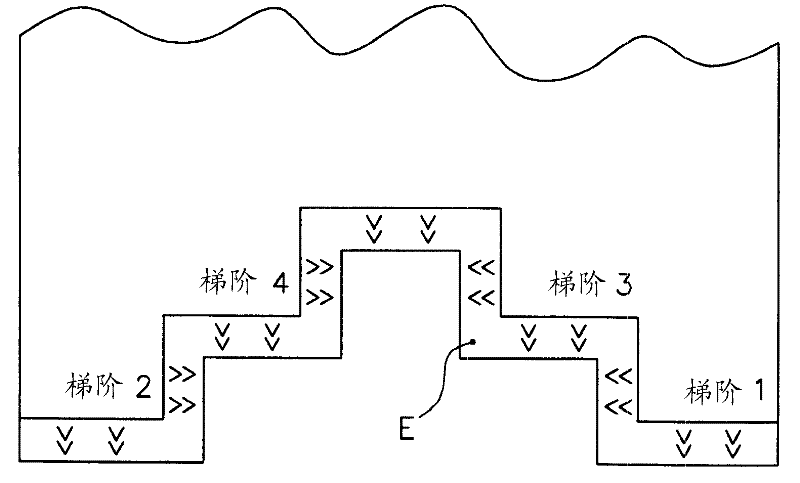

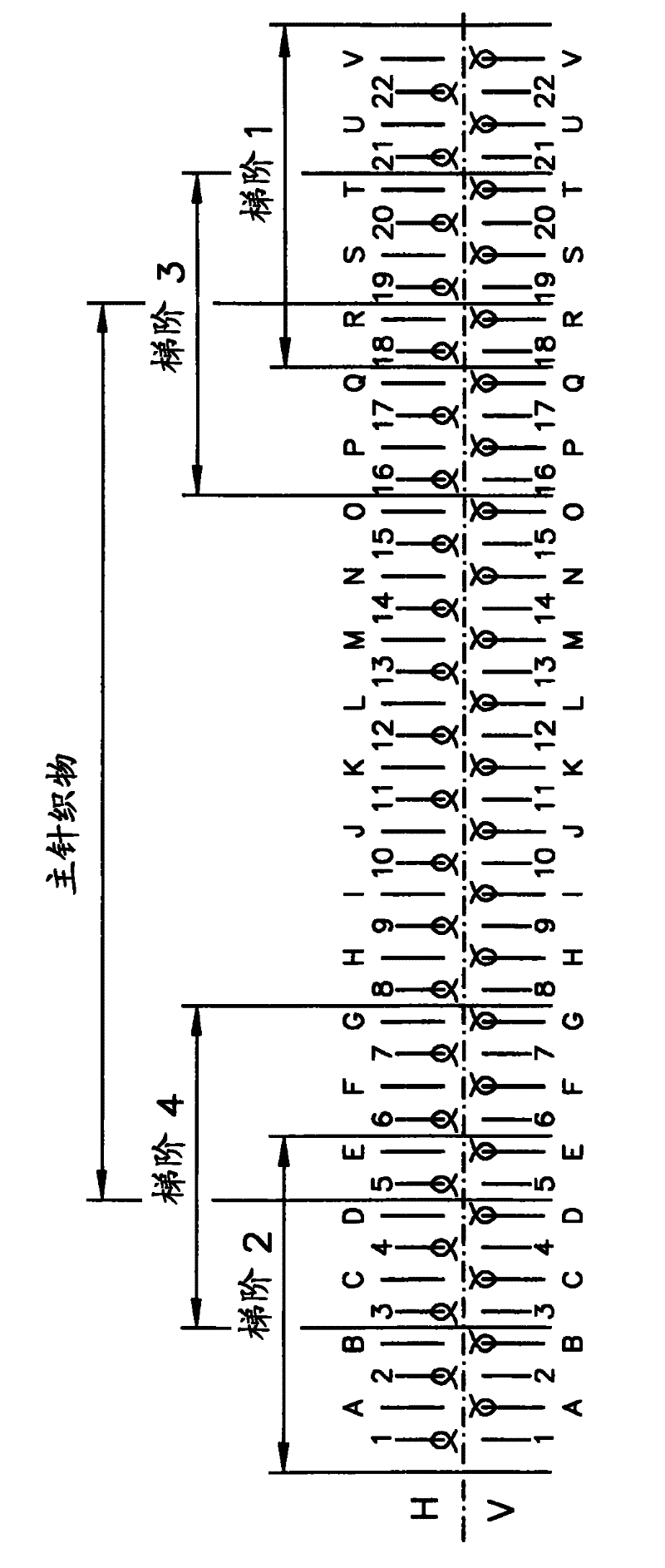

[0026] figure 1 is a detailed view of the lower edge region of a garment or jacket provided with four steps in the front and back body of the tubular former knit. The main knit HG is provided with a trim E along the lower edge. According to the method according to the invention, an edge E is first produced, for which all conceivable jacquard techniques are conceivable, in particular as a circular knit or rib knit. Next, the main knitted fabric HG is formed, and the trim E is attached to the stepped lower edge.

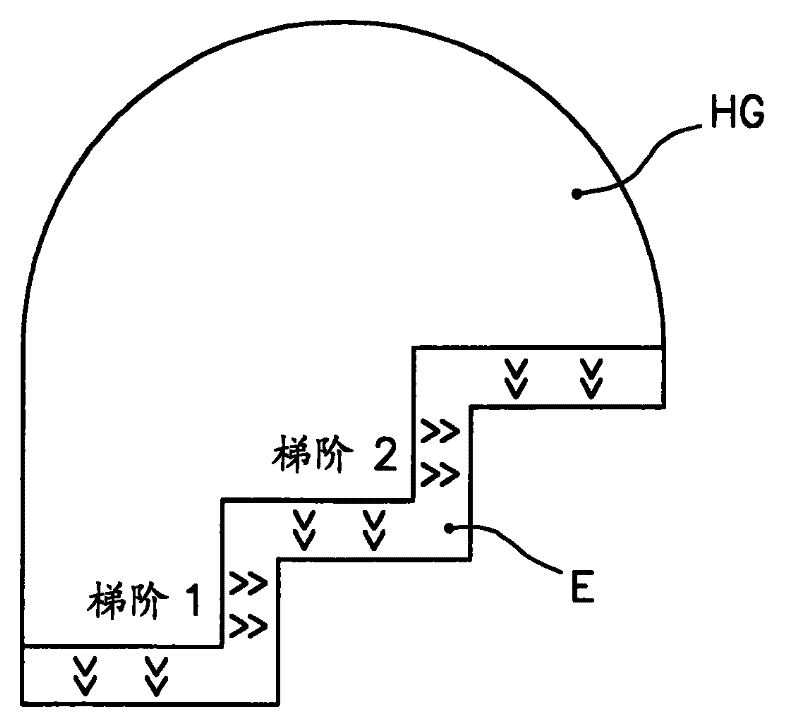

[0027] figure 2 Another tubular knitted fabric in the form of a cap is shown, which is provided with stepped side edges in order to form the earmuffs. For this kind of circular formed product knitted fabric, the edge decoration E is also woven first, and then the steps 1 and 2 of the main knitted fabric HG are knitted successively, wherein the edge decoration is either in the direction parallel to the stitch course or in the vertical direction. In the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com