Large overfeed roller for textile machinery

A technology of textile machinery and large overfeeding, which is applied to the elongation of fabrics, textiles and papermaking, and fabric surface trimming. It can solve the problems of inability to adjust the speed of large overfeeding rollers in real time, inconvenient transportation and installation, and large moment of inertia. Achieve the effect of reducing the moment of inertia and mass, ensuring stable rotation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

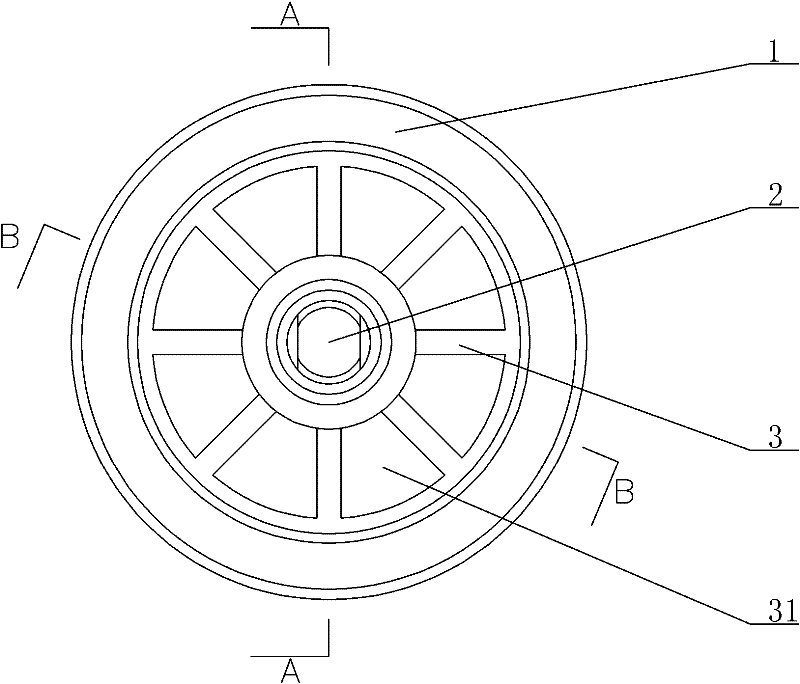

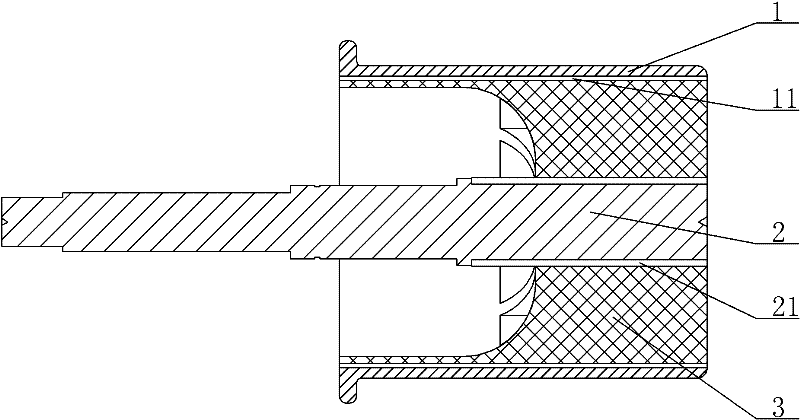

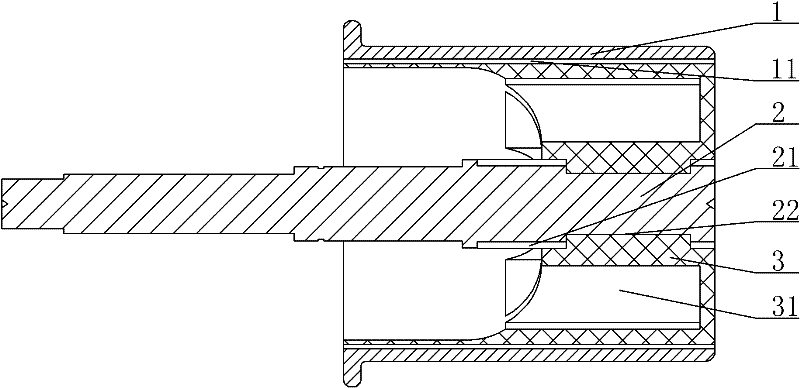

[0020] Below in conjunction with accompanying drawing, the preferred embodiment of the large overfeed roller on a kind of textile machine of the present invention is described in detail:

[0021] Such as figure 1 As shown, the main body of the large overfeed roller is a concentric steel sleeve outer ring 1, a mandrel 2 and a plastic part 3 that fixes the relative positions of the two. The outer ring 1 of the steel sleeve is a steel cylinder, the outer surface is polished smooth, and the inner wall is provided with internal anti-slip lines 11, which are cross internal threads; the mandrel 2 is a steel round stick shaft, which is concentric with the outer ring 2 of the steel sleeve. There are outer anti-slip lines 21 on the surface of the shaft 2, which are reticular patterns, and the part of the mandrel 2 located in the outer ring 2 of the steel sleeve is polished into a special-shaped shaft 22, which is a section of cylindrical shaft with two short planes on the surface. Shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com