Abnormal sound diagnostic instrument of automobile body chassis

A diagnostic instrument and chassis technology, applied in the field of automobile maintenance auxiliary equipment, can solve problems such as traffic risks, affecting customers' use of vehicles, and headaches for repairmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the vehicle body chassis abnormal sound diagnostic instrument proposed according to the present invention will be described in detail as follows.

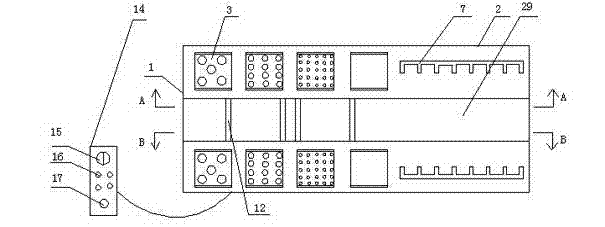

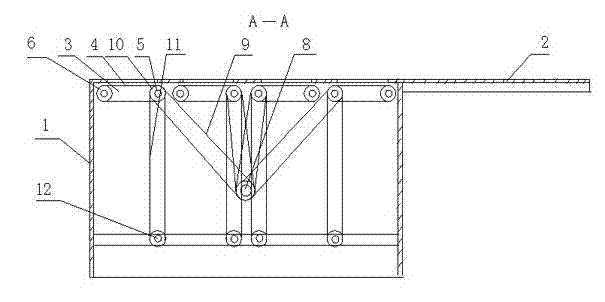

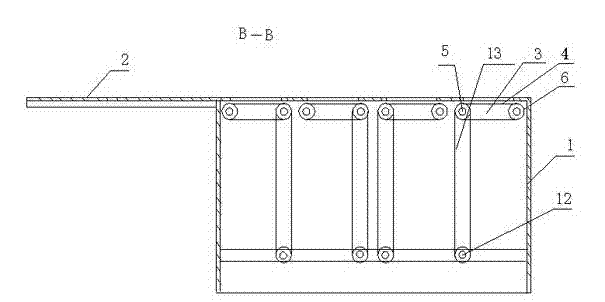

[0021] see Figure 1-4 , The car body chassis abnormal sound diagnostic instrument of the present invention comprises a test platform 2, a chassis 1, and the test platform 2 is fixed on the chassis 1. Simulated road crawlers 3 are symmetrically distributed on both sides of the front end of the test platform 1, and tires are symmetrically arranged on both sides of the rear end. The positioning groove 7, the simulated road track 3 symmetrically distributed on both sides are connected sequentially through the belt A11, the transmission shaft 12, and the belt B13; A number of anti-skid strips 24 are evenly distributed. The main drum 5 and the slave drum 6 are located inside the endless cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com