Method for controlling stepless adjustment of water-source screw unit

A stepless regulation, screw unit technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of poor oil return of the unit, affecting the safety and reliability of the unit, and achieve effective loading and unloading actions. Reliable, increase the accuracy of judgment, and the effect of accurate spool valve position

Active Publication Date: 2011-09-21

TONGFANG ARTIFICIAL ENVIRONMENT

View PDF3 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing stepless adjustment technology of water source of the screw unit still has the disadvantages of whether the compressor can reach full load after starting; when the compressor works in the holding area or full load area for a long time, there will be a retreat phenomenon caused by the oil leakage of the slide valve; When working under partial load for a long time, the unit will have the problem of poor oil return, which will affect the safety and reliability of the unit operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

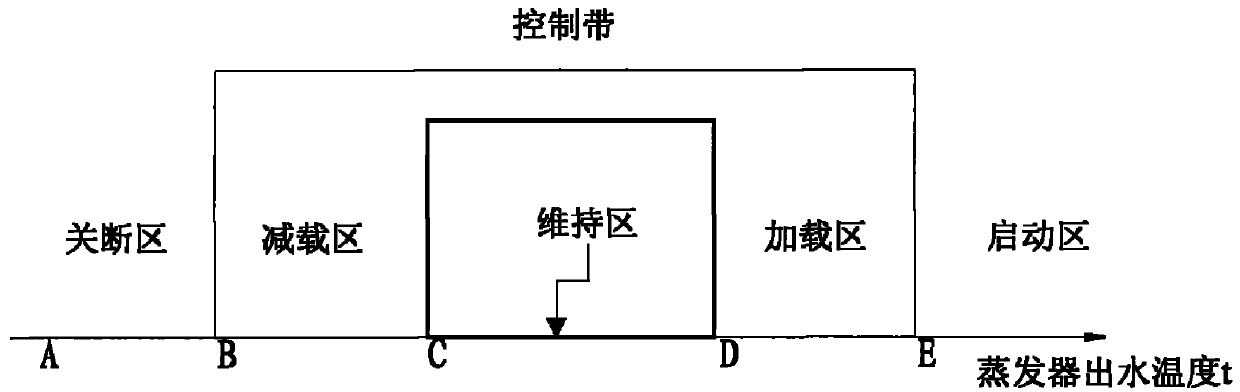

The invention discloses a method for controlling the stepless adjustment of a water-source screw unit, which belongs to the technical field of air-conditioning refrigeration. The method is implemented by carrying out pulse control on a loading valve or an unloading valve according to the measurement on the temperature t of discharged water performed by using a NTC (negative temperature coefficient) temperature measuring head. The method comprises the following steps: (1) startup: a main compressor is started for providing a sustained pulse for the loading valve, so that the main compressor carries out rapid loading; (2) loading: a controller transmits a loading pulse to the loading valve so as to carry out system loading, and accumulates the loading time; (3) keeping: the compressor does not carry out loading and lightening actions; (4) lightening: the controller transmits a lightening pulse to the loading valve so as to carry out system lightening, and accumulates the lightening time; (5) stoping: the unloading electromagnetic valve is powered on so as to ensure the compressor completes a shut-down process; and (6) forced stopping: the main compressor and a sub-compressor are powered off and shut down. In the method disclosed by the invention, the stepless adjustment of the water-source screw unit is controlled based on pulse time, the temperature control is correct, the stepless adjustment is reliable and efficient, and the safe and stable operation of the unit is ensured.

Description

A control method for stepless adjustment of water source screw unit technical field The invention relates to the technical field of air-conditioning and refrigeration, in particular to a control method for a steplessly regulated water source screw unit. Background technique The stepless adjustment of the screw unit is mostly controlled according to the outlet water temperature, and the energy output of the compressor is effectively adjusted according to the actual cooling load, reducing the frequent start and stop of the compressor, prolonging the service life of the compressor, and achieving the purpose of energy saving . In the prior art, the stepless adjustment of the slide valve usually uses a negative temperature coefficient NTC temperature probe to measure the outlet water temperature, and performs pulse control on the loading and unloading solenoid valves to make the energy stepless adjustment in the energy-saving economic zone. The single compressor can continuou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05D23/20

Inventor 赵濂支爱华刘建龙

Owner TONGFANG ARTIFICIAL ENVIRONMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com