Battery pack with guide plate

A technology for battery packs and batteries, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as complex structures and achieve efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

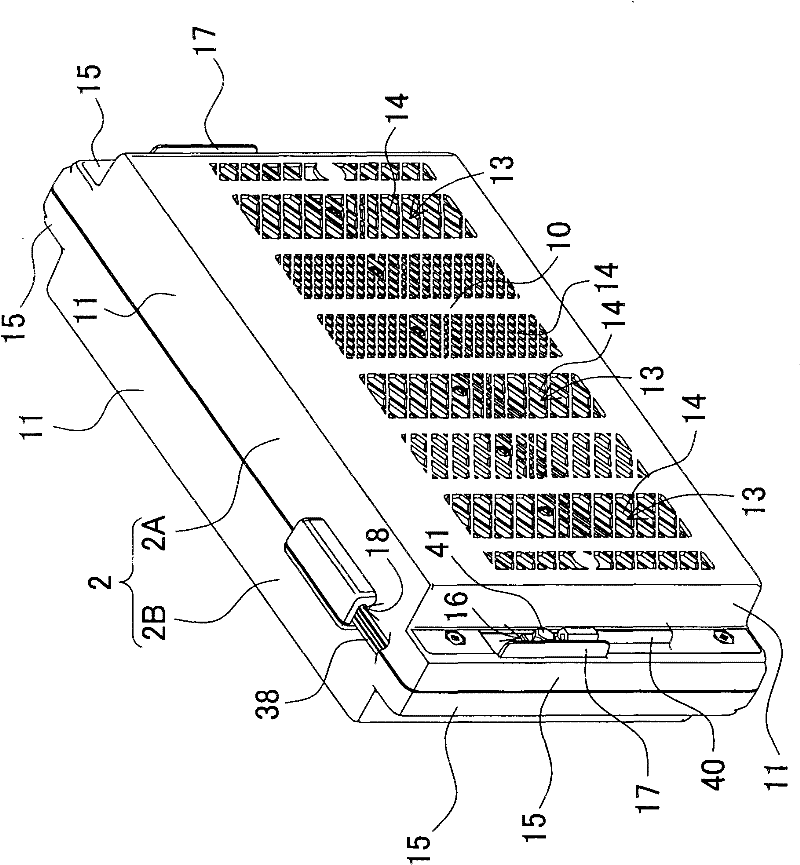

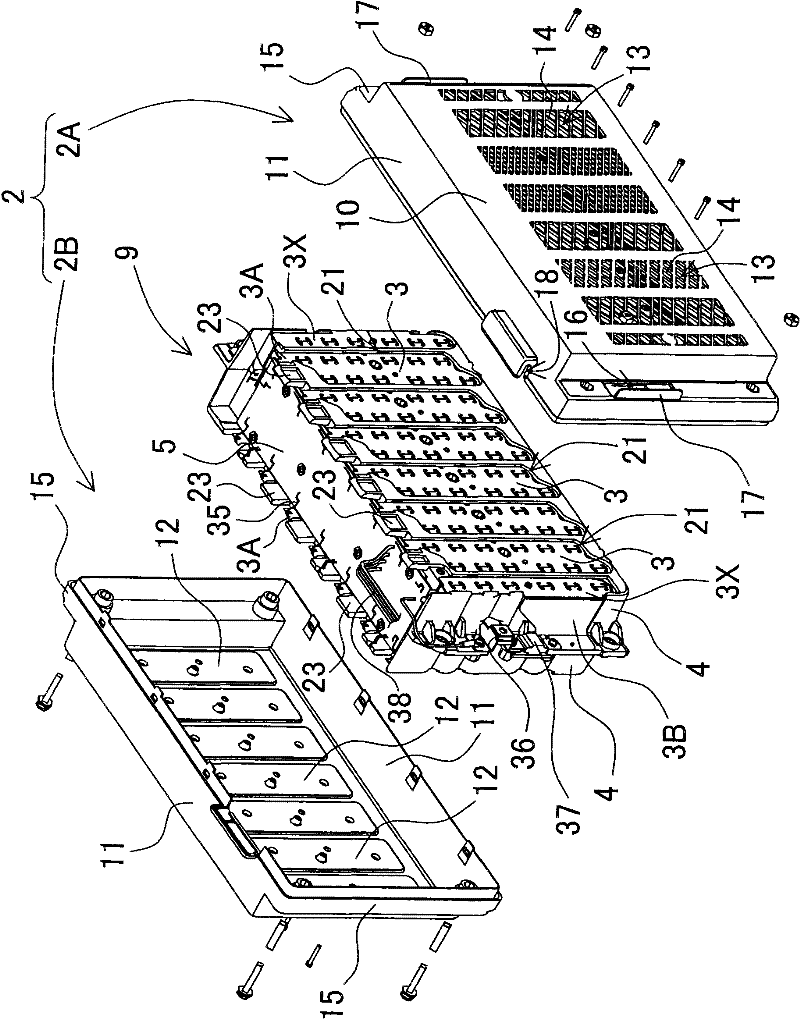

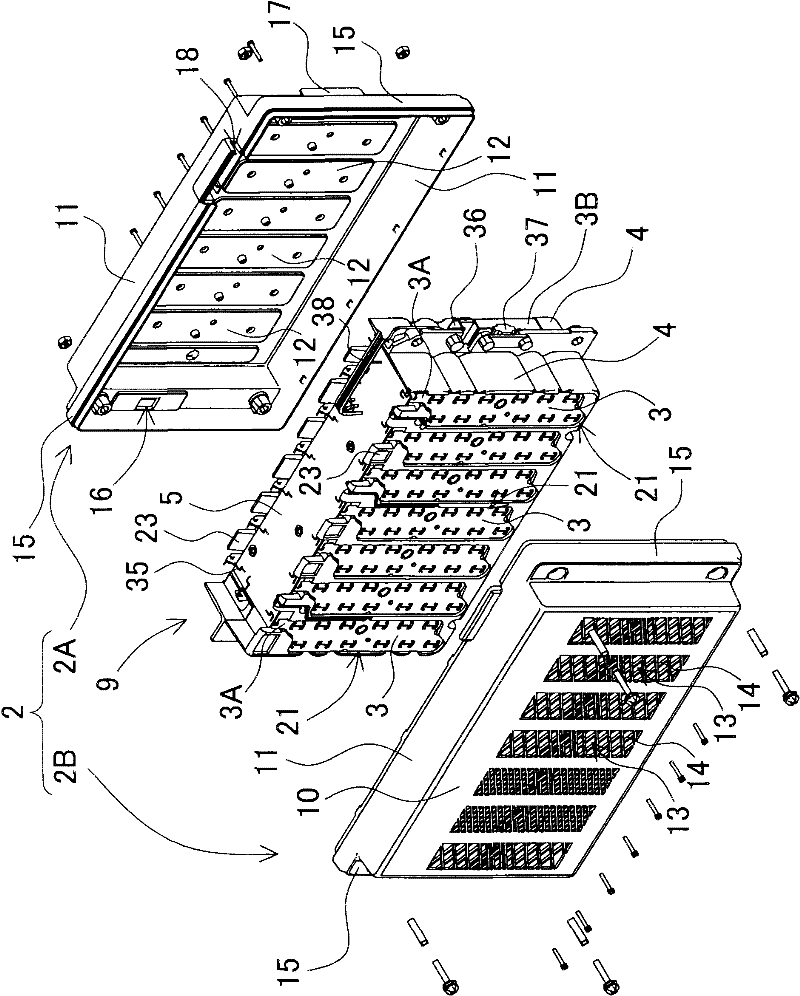

[0031] Next, embodiments of the present invention will be described with reference to the drawings. Figure 1 to Figure 6 The battery pack accommodates the battery pack 9 in the exterior case 2 . The battery pack 9 connects a plurality of rechargeable batteries 1 in series and in parallel through the guide plate 3 .

[0032] [Exterior case]

[0033] figure 2 , image 3 and Image 6 The illustrated exterior case 2 has a box shape having a heat dissipation case portion 10 for dissipating heat from the battery 1 on the opposing surface, and accommodates the battery pack 9 inside. Although the exterior case 2 in the drawings is provided with the heat dissipation case portion 10 on two opposing surfaces, the exterior case may also be provided with the heat dissipation case portion only on one of the opposite surfaces. The exterior case 2 in the drawing has a shape in which the outer shape of the heat dissipation case part 10 is a square, and the periphery of the square is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com