Automobile LED headlamp

A technology for headlights and automobiles, which is applied to headlights, motor vehicles, road vehicles, etc., can solve the problems of high processing cost, inconvenient installation, and high processing accuracy, achieve low processing accuracy requirements, reduce occupied space, and solve heat dissipation problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

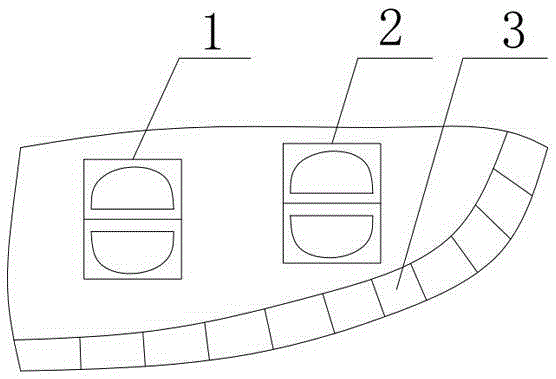

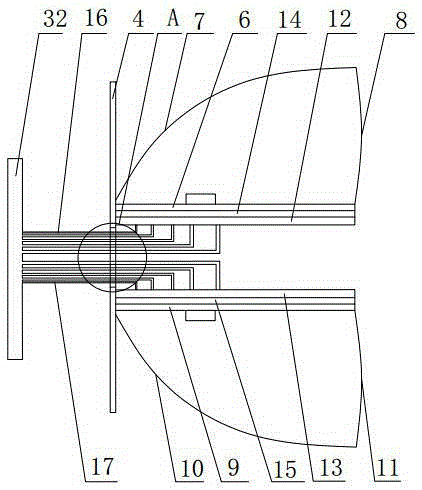

[0033] An automobile LED headlamp, comprising a lamp housing and a lampshade, a high beam unit 1, a low beam unit 2 and a turn signal unit 3 are arranged between the lamp housing and the lampshade,

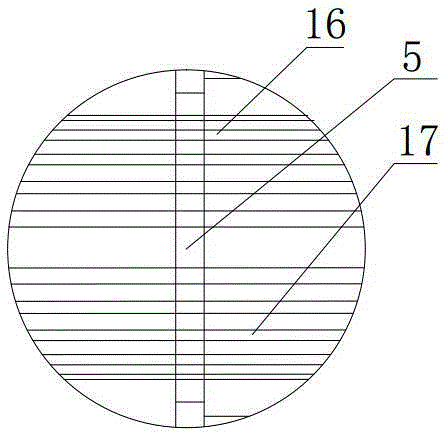

[0034] The high beam unit includes a first mount 4 arranged on the lamp housing, a first heat dissipation through hole 5 is provided in the middle of the first mount 4, and the first heat dissipation through hole of the first mount 4 5 Both sides are provided with a first high-beam lighting unit and a second high-beam lighting unit, the first high-beam lighting unit includes a first aluminum substrate 6 vertically arranged on the first mount 4, The LED chip on the substrate 6, the first parabolic reflector 7 used to reflect the light generated by the LED chip, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com