Needle valve type hot runner system

A needle-valve hot runner and valve needle technology, which is applied in the field of hot runner system, can solve the problems of affecting fluid outflow, valve needle vibration, driving force and pressure maintenance are not very stable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

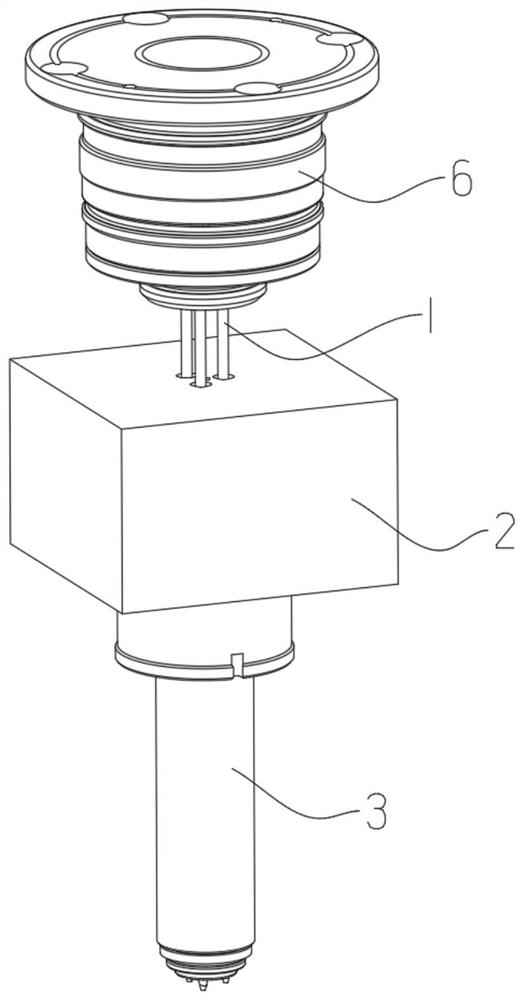

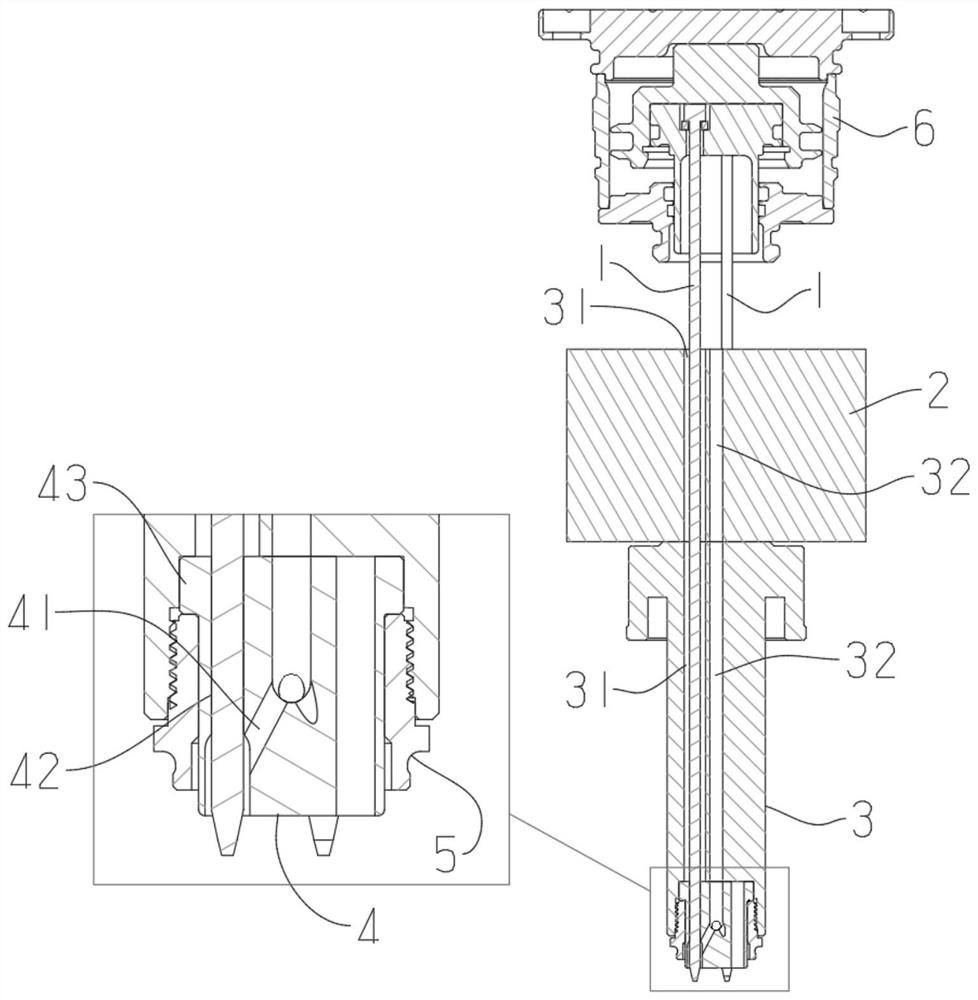

[0040] A valve needle hot runner system, such as Figure 1 to Figure 4 As shown: the hot runner system includes valve needle 1, manifold 2 and hot nozzle assembly 3;

[0041] The diverter plate is arranged at one end of the thermal nozzle assembly, the other end of the thermal nozzle assembly is the discharge end, and the diverter plate and the thermal nozzle assembly have a valve needle hole 31 communicating with each other. The valve needle is passed through the valve needle hole, and the valve needle can reciprocate along its axial direction;

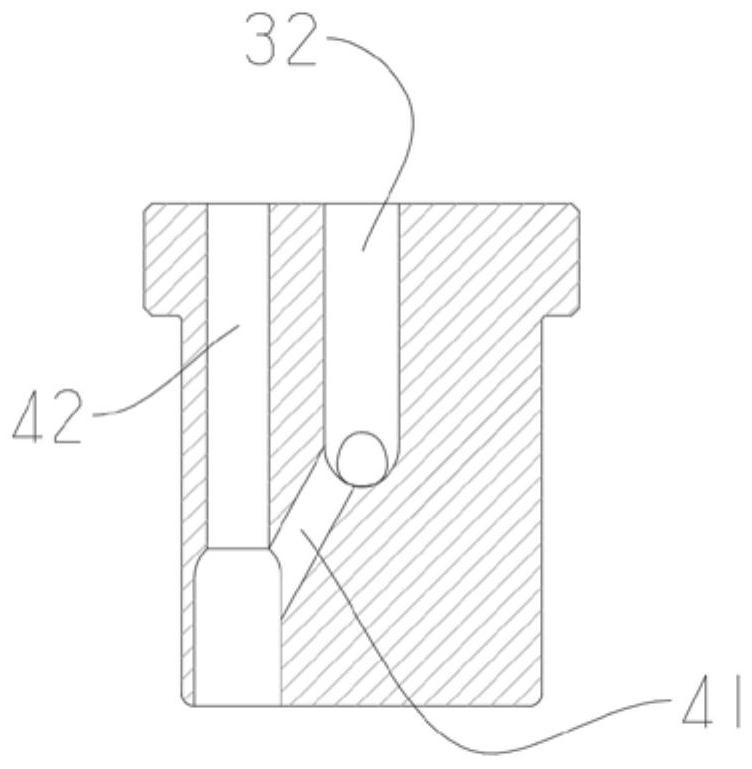

[0042] The splitter plate and the thermal nozzle assembly have a main channel 32 communicating with each other, and the discharge end of the thermal nozzle assembly is provided with a valve needle cover 4, and the valve needle cover has a branch channel communicated with the main channel. 41, and has a positioning hole 42 communicated with the valve pin hole, the shunt channel communicates with the positioning hole, the valve pin pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com