4-diphenyl formate/leuh nanometer complex and synthetic method

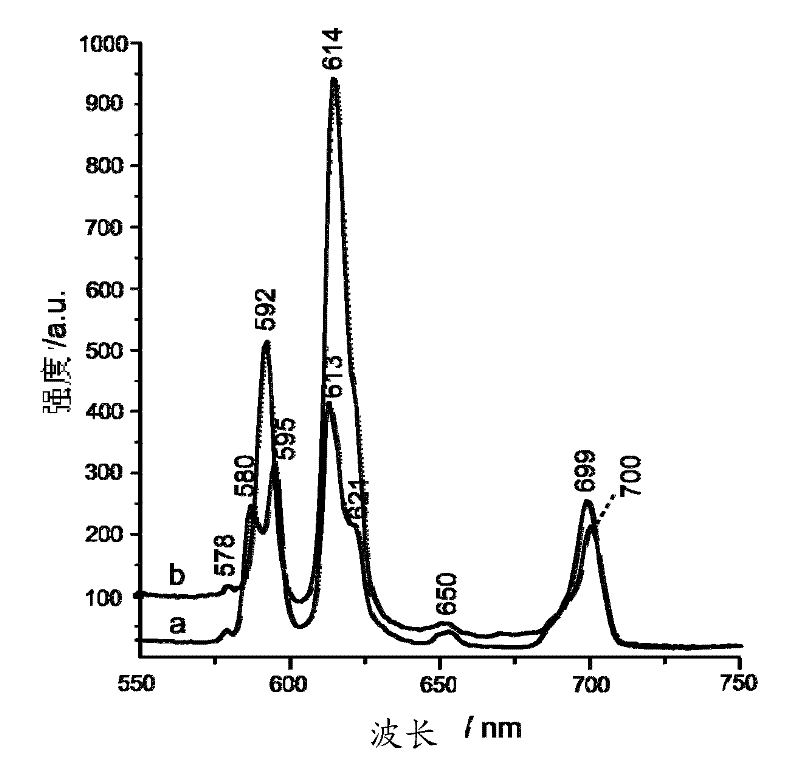

A technology of nanocomposites and biphenylformic acid, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of fluorescence intensity not meeting industrial needs, fluorescence quenching, etc., and achieve improved energy transfer efficiency, high stability, and luminescence The effect of performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The synthetic method of above-mentioned 4-biphenylcarboxylate / LEuH nanocomposite, comprises the following steps:

[0047] a) Preparation of Eu(OH) by homogeneous precipitation method 2.5 Cl 0.5 ·nH 2 O: EuCl 3 ·6H 2O, NaCl and HMT (hexamethylenetetramine) are dissolved in water, where EuCl 3 ·6H 2 The molar ratio of O, NaCl and HMT is preferably 0.5-1.5: 10-15: 0.5-1.5, preferably dissolved in exhaust water, which refers to the removal of CO 2 The water can be obtained by boiling distilled water for 5 minutes. The amount of exhaust water is preferably 50mL-100mL / 1mmolEuCl 3 ·6H 2 O. N was then introduced into the solution 2 , after 20min to 40min, the hydrothermal reaction is carried out, the preferred reaction temperature is 90°C to 120°C, and the reaction time is 10h to 12h.

[0048] After the reaction is completed, filter, wash the product with distilled water, and finally dry at room temperature to obtain Eu(OH) 2.5 Cl 0.5 ·nH 2 O, also can be abbrevia...

Embodiment 1

[0053] a) 1mmol EuCl 3 ·6H 2 O, 13mmol NaCl, 1mmol HMT dissolved in 80mL exhaust water, pass through N 2 30min, 90°C hydrothermal reaction for 12h. Then suction filtered, washed with distilled water, and dried at room temperature to obtain Cl-LEuH.

[0054] b) Disperse 0.05g of prepared Cl-LEuH in 80mL of 4-biphenylcarboxylic acid sodium salt solution, which contains 3 times of Cl-LEuH molar excess of 4-biphenylcarboxylic acid, and the molar ratio is 1:0.5 4-diphenylformic acid and NaOH mixed in the system, pH = 8.8. Then it was transferred to a 100mL reactor and reacted with water at 70°C for 40h. Finally, it was filtered, washed with distilled water, and dried at room temperature.

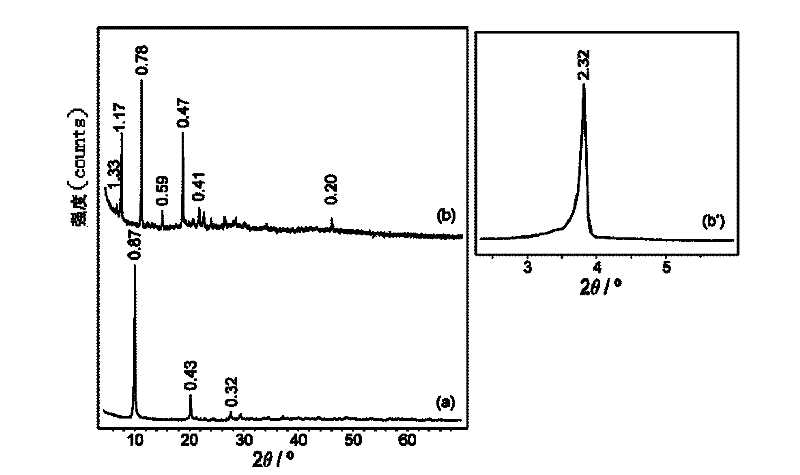

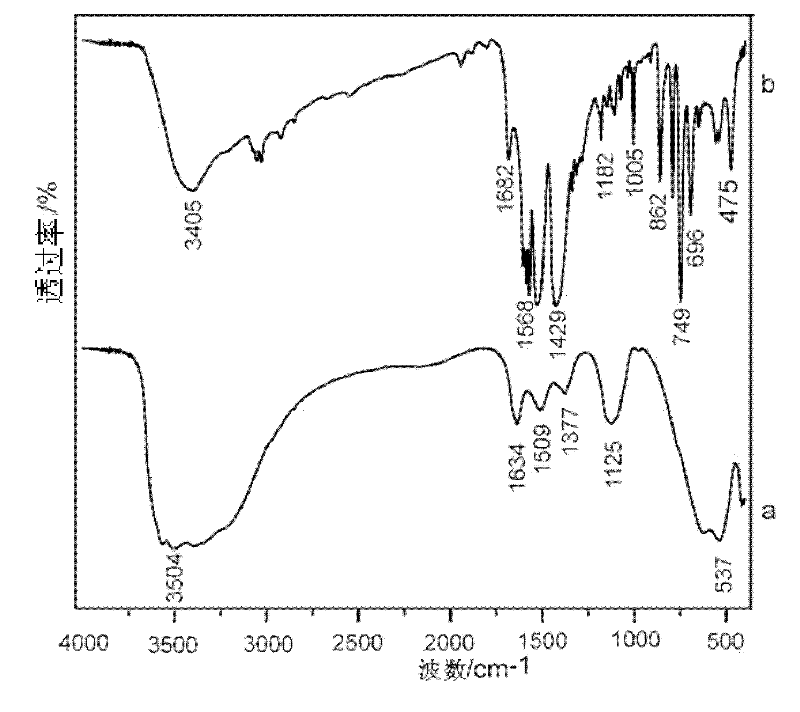

[0055] Please refer to figure 1 , figure 1 XRD (X-ray diffraction, X-ray diffraction) patterns of Cl-LEuH and 4-bibenzoate / LEuH prepared in Example 1 of the present invention. Wherein figure a is the XRD figure of Cl-LEuH, can see 0.87nm, 0.43nm, 0.32nm a series of characteristic diffract...

Embodiment 2

[0060] a) 0.8mmol EuCl 3 ·6H 2 O, 14mmol NaCl, 1.2mmol HMT dissolved in 100mL exhaust water, pass N 2 40min, 100°C hydrothermal reaction for 10h, then suction filtration, washing with distilled water, and drying at room temperature to obtain Cl-LEuH.

[0061] b) Disperse 0.05g of prepared Cl-LEuH in 80mL of 4-biphenylcarboxylic acid sodium salt solution, which contains 3 times of Cl-LEuH molar excess of 4-biphenylcarboxylic acid, and the molar ratio is 1:0.75 4-biphenylformic acid and NaOH mixed in the system, pH = 8.6. Transfer to a 100mL reactor and react with water at 120°C for 24h. Finally, it was filtered, washed with distilled water, and dried at room temperature.

[0062] Please refer to Figure 4 , Figure 4 It is the XRD pattern of Cl-LEuH and 4-bibenzoate / LEuH prepared in Example 2 of the present invention. Wherein figure a is the XRD figure of Cl-LEuH, can see 0.87nm, 0.43nm, 0.32nm a series of characteristic diffraction peaks, peak shape is sharp, the Cl obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com