Cooling device for V-type diesel engine

A cooling device and diesel engine technology, applied in engine cooling, liquid cooling, mechanical equipment, etc., can solve the problems of complex peripheral pipelines, bulky whole machine, heavier weight of the whole machine, etc., achieve broad market prospects and simplify the body structure , the effect of improving the stiffness of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

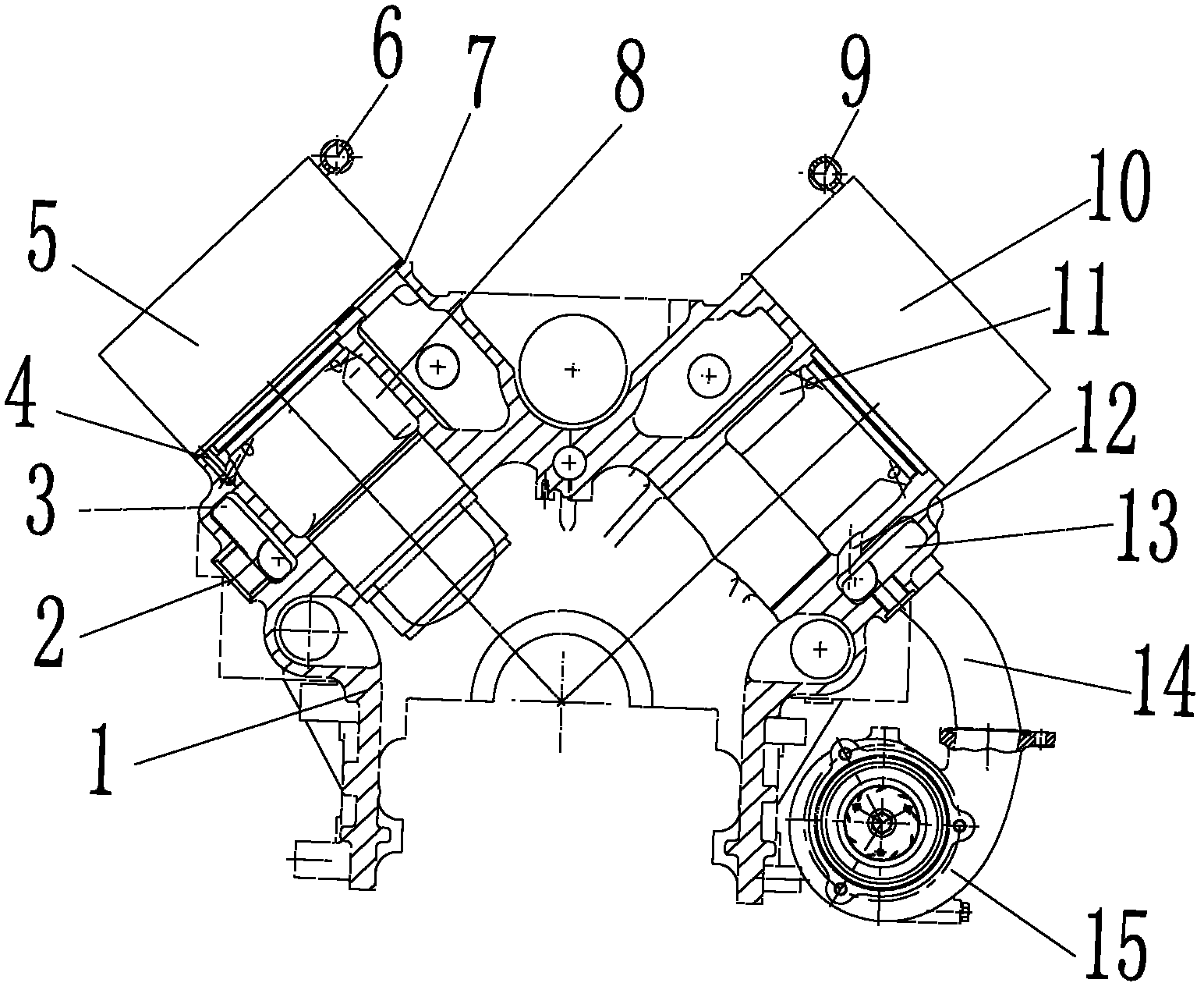

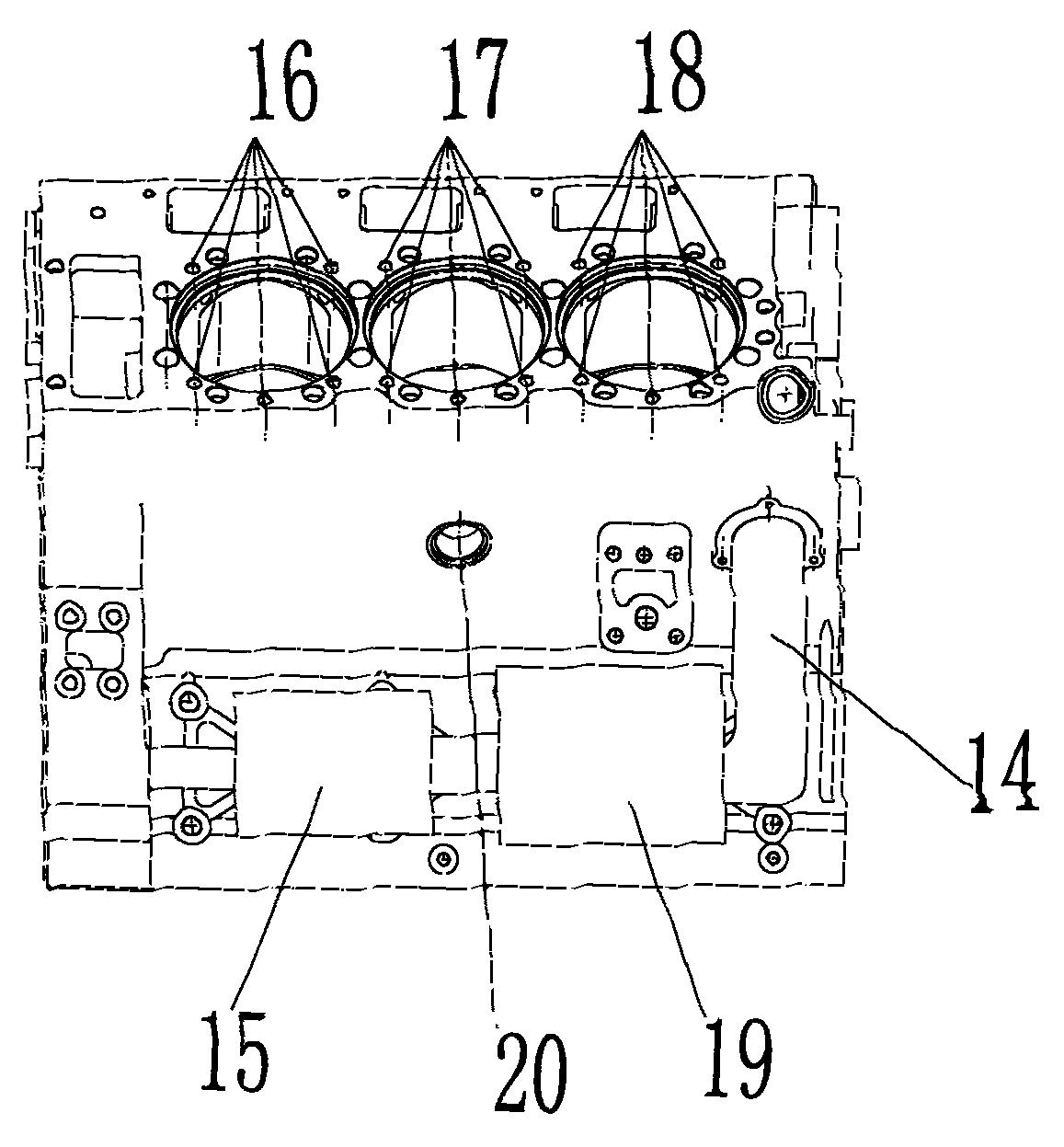

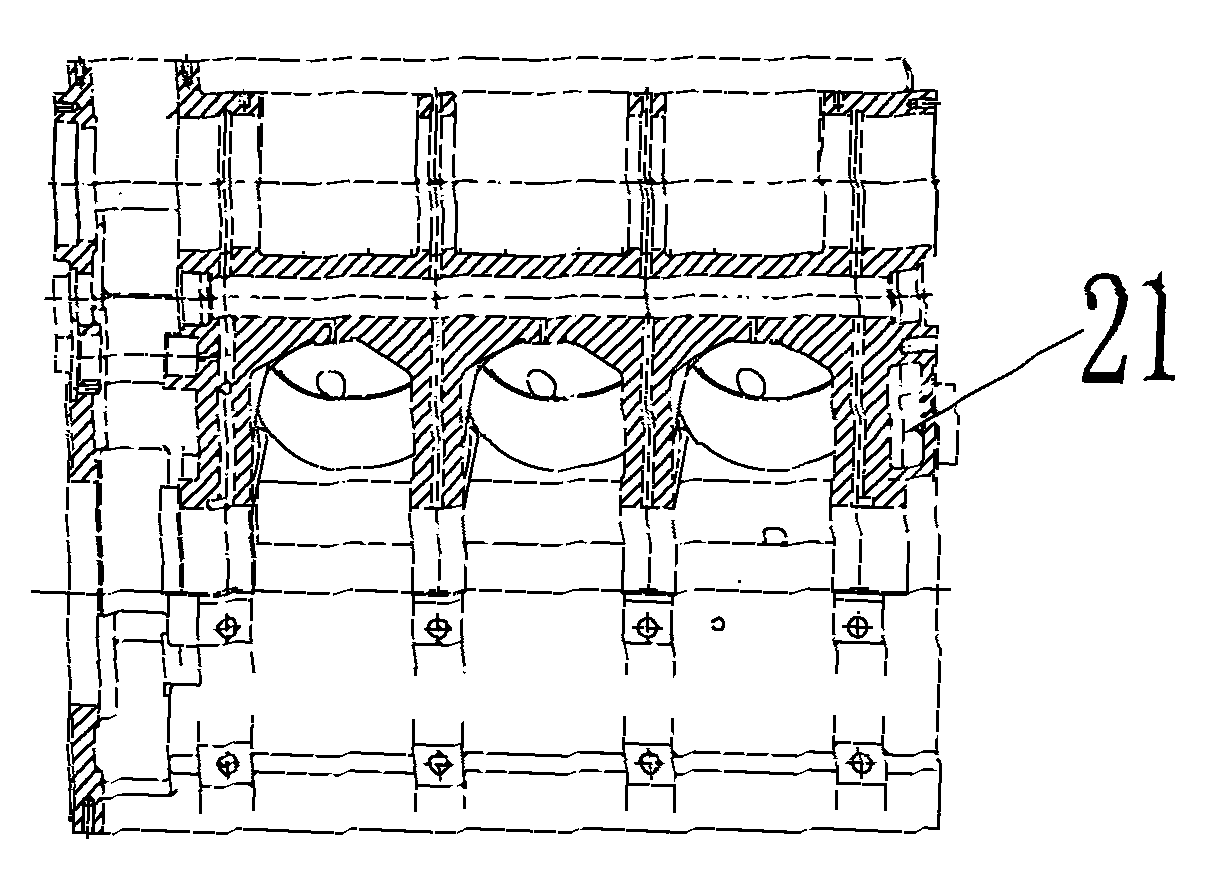

[0009] A V-type diesel engine cooling device, which includes a body 1, a first screw plug 2, a first cylinder head water chamber 5, a first return water pipe 6, a cylinder gasket 7, a second return water pipe 9, and a second cylinder head water chamber 10 , a water inlet pipe 14, a water pump 15, an oil heat exchanger 19 and a second screw plug 20, the body 1 is provided with a first longitudinal water channel 3, a water cavity 8 on the left side of the body, a water cavity 11 on the right side of the body, an internal water channel 12, a second Two longitudinal water channels 13, horizontal water channels 21, internal water channels 12, horizontal water channels 21 communicate with the first longitudinal water channel 3 and the second longitudinal water channel 13, the first cylinder head water chamber 5 is connected with the left water chamber 8 of the body, and the cylinder gasket 7 is respectively It is arranged between the first cylinder head water chamber 5 and the left w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap