Aerostatic thrust bearing

A technology of thrust bearings and air static pressure, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of small load capacity, poor stability, low rigidity, etc., to reduce thermal deformation, improve radial stiffness, and enhance The effect of bearing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the working principle, structure and specific implementation of the present invention will be further introduced below in conjunction with the accompanying drawings.

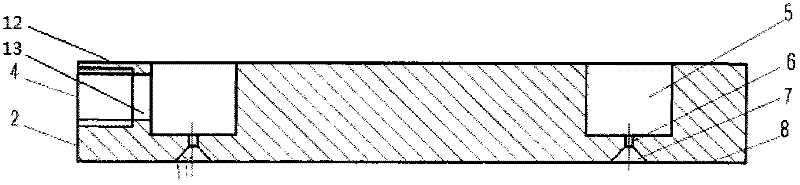

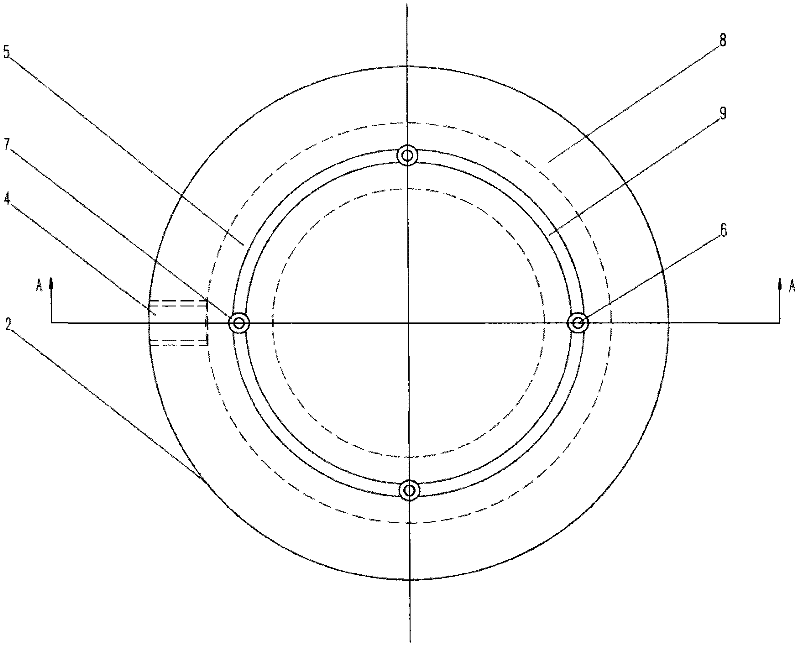

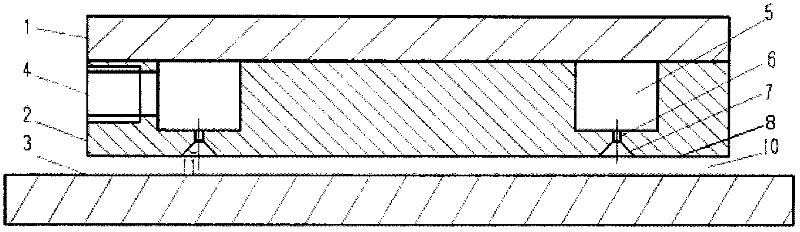

[0019] like figure 1 , figure 2 and image 3 A schematic diagram of the structure of the aerostatic thrust bearing provided by the present invention is shown. The bearing includes a supported part 1 , a bearing body 2 and a smooth plane 3 .

[0020] The aerostatic thrust bearing includes a supported part 1, a bearing body 2 and a smooth plane 3;

[0021] The bearing body 2 is provided with an air inlet 4, an annular groove 5, a plurality of throttle holes 6, a plurality of air cavities 7, a bearing working surface 8 and a pressure equalizing groove 9; the bearing body 2 also has an upper plane 12; the air cavity 7 is provided with an inlet port connected to the throttle hole 6 and a jet port located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com