Liquid crystal dripping device with temperature control

A liquid crystal dropping and temperature control technology, applied in the direction of temperature control, electric temperature control, non-electric variable control, etc., can solve the problem of increasing the liquid crystal injection process time, uneven display of the dripping graphics, and increasing the operation accuracy of the liquid crystal dripping quantity. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention are exemplified below and described in detail in conjunction with the accompanying drawings. Furthermore, the directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., It is only for orientation with reference to the attached drawings. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

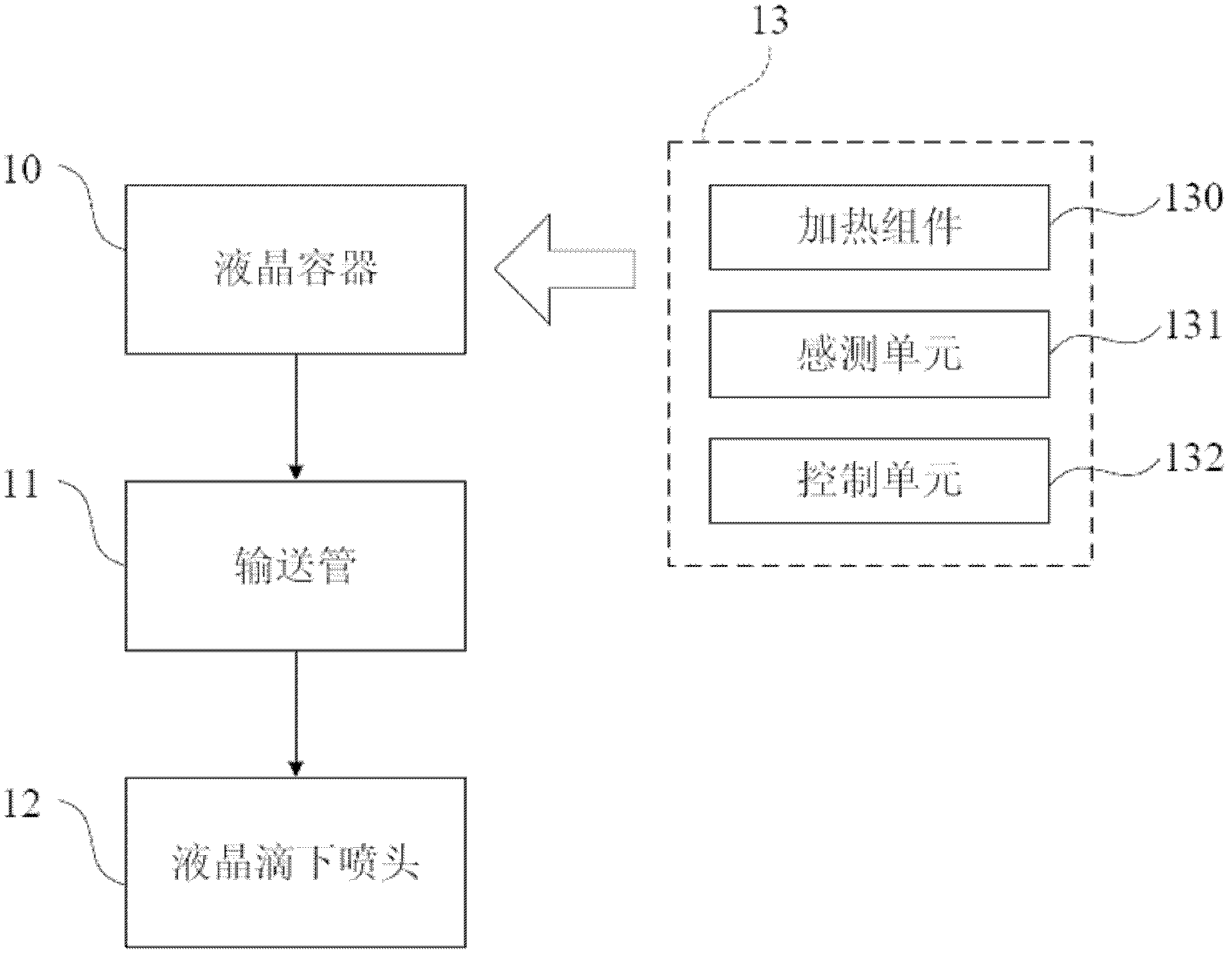

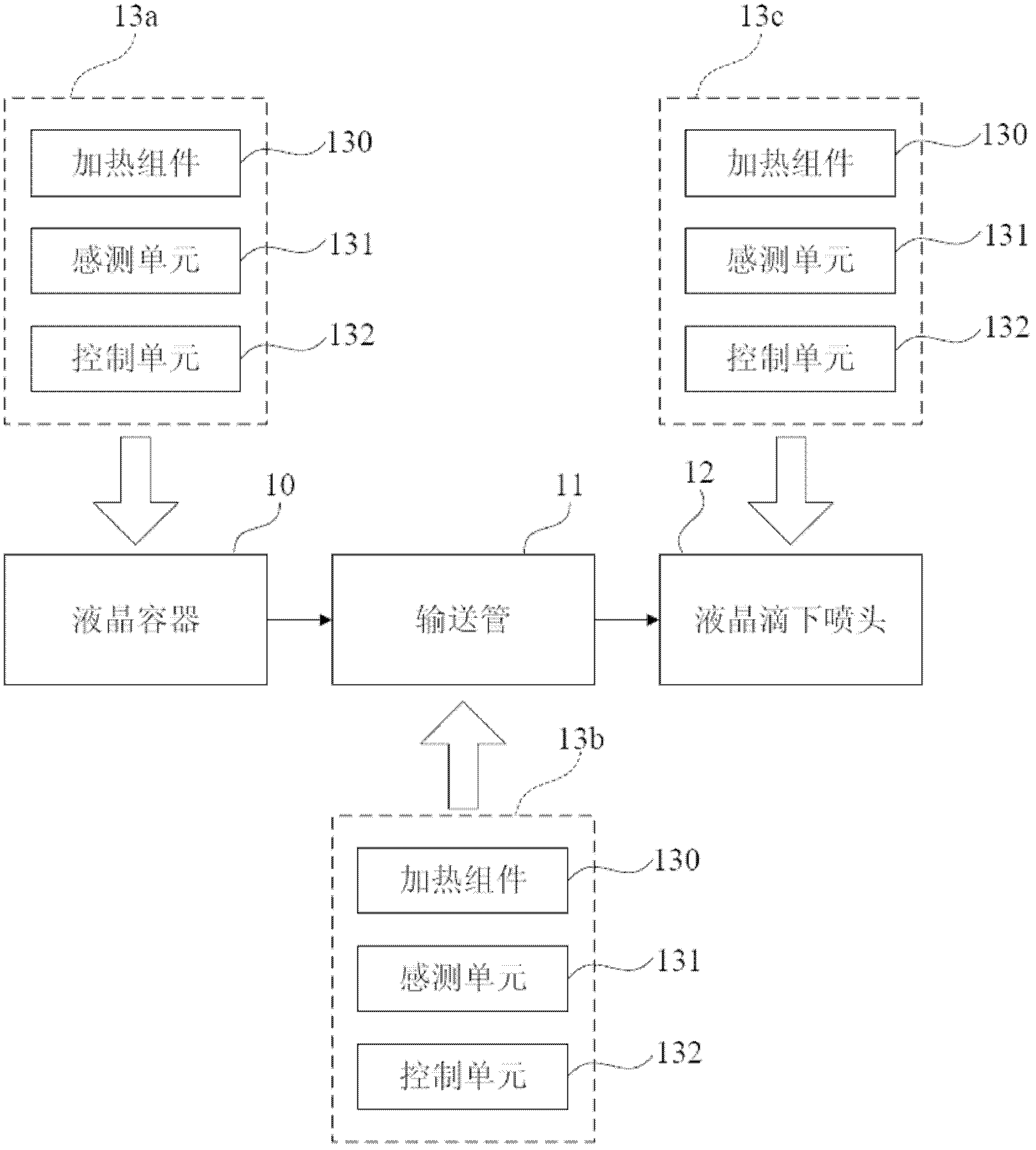

[0024] Please refer to figure 2 as shown, figure 2 It is a block diagram of the first embodiment of the liquid crystal dropping device with temperature control of the present invention. The liquid crystal dropping device with temperature control of the present invention includes a liquid crystal container 10 , a conveying pipe 11 , a liquid crystal dropping no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com