Steel piece hot scarfing device and nozzle clogging detection method thereof

A technology of flame cleaning and blockage detection, which is applied in combustion methods, gas flame welding equipment, lighting and heating equipment, etc., and can solve problems such as the influence of steel billet flame cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

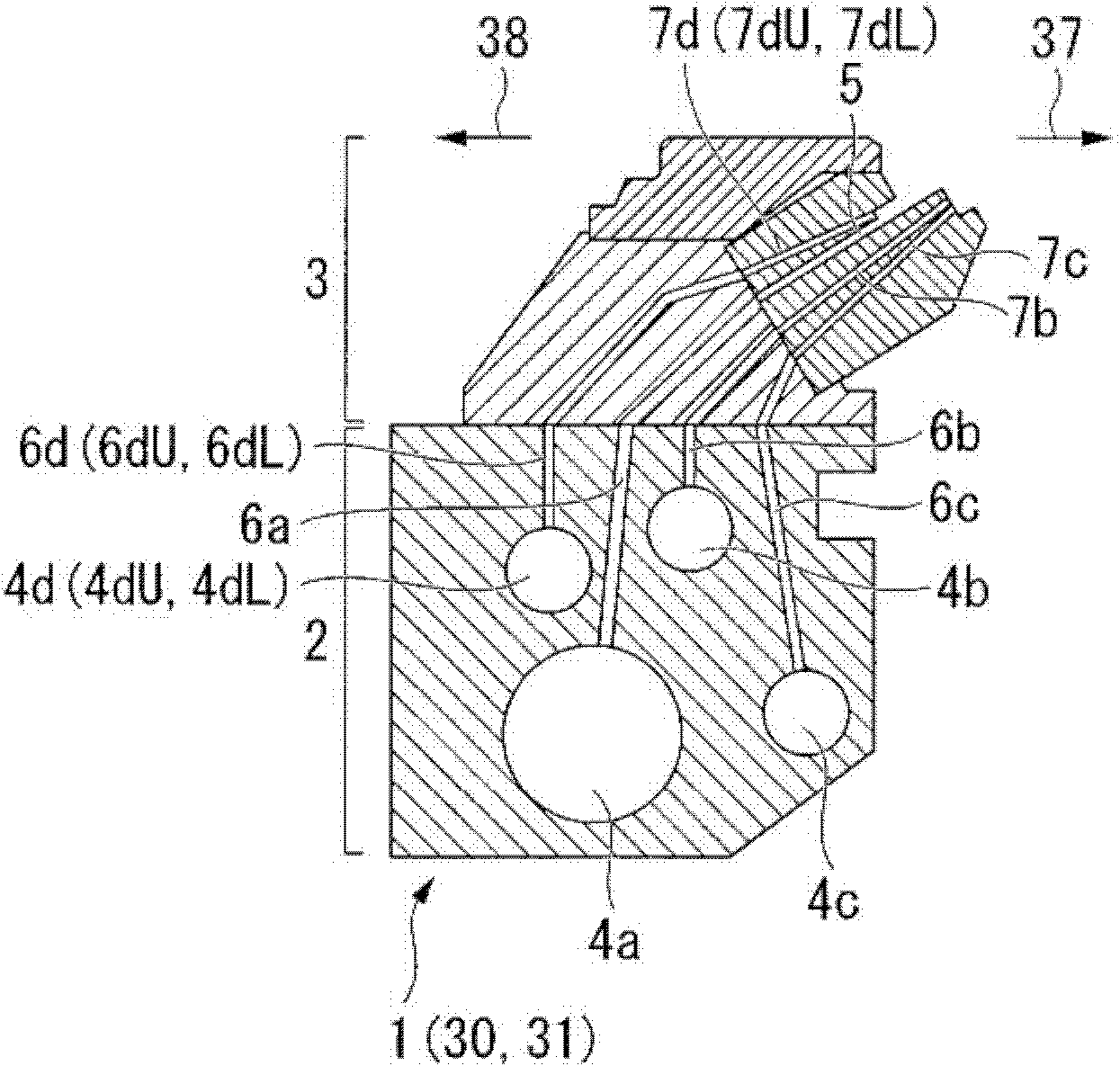

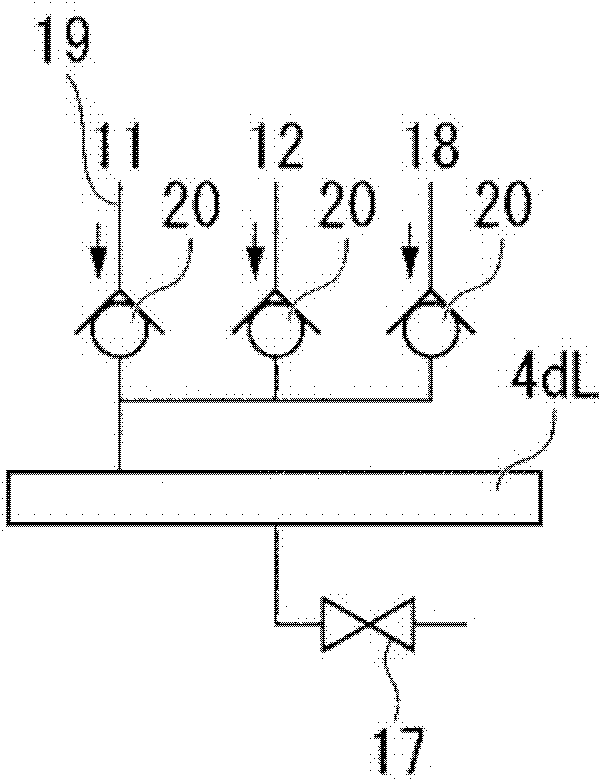

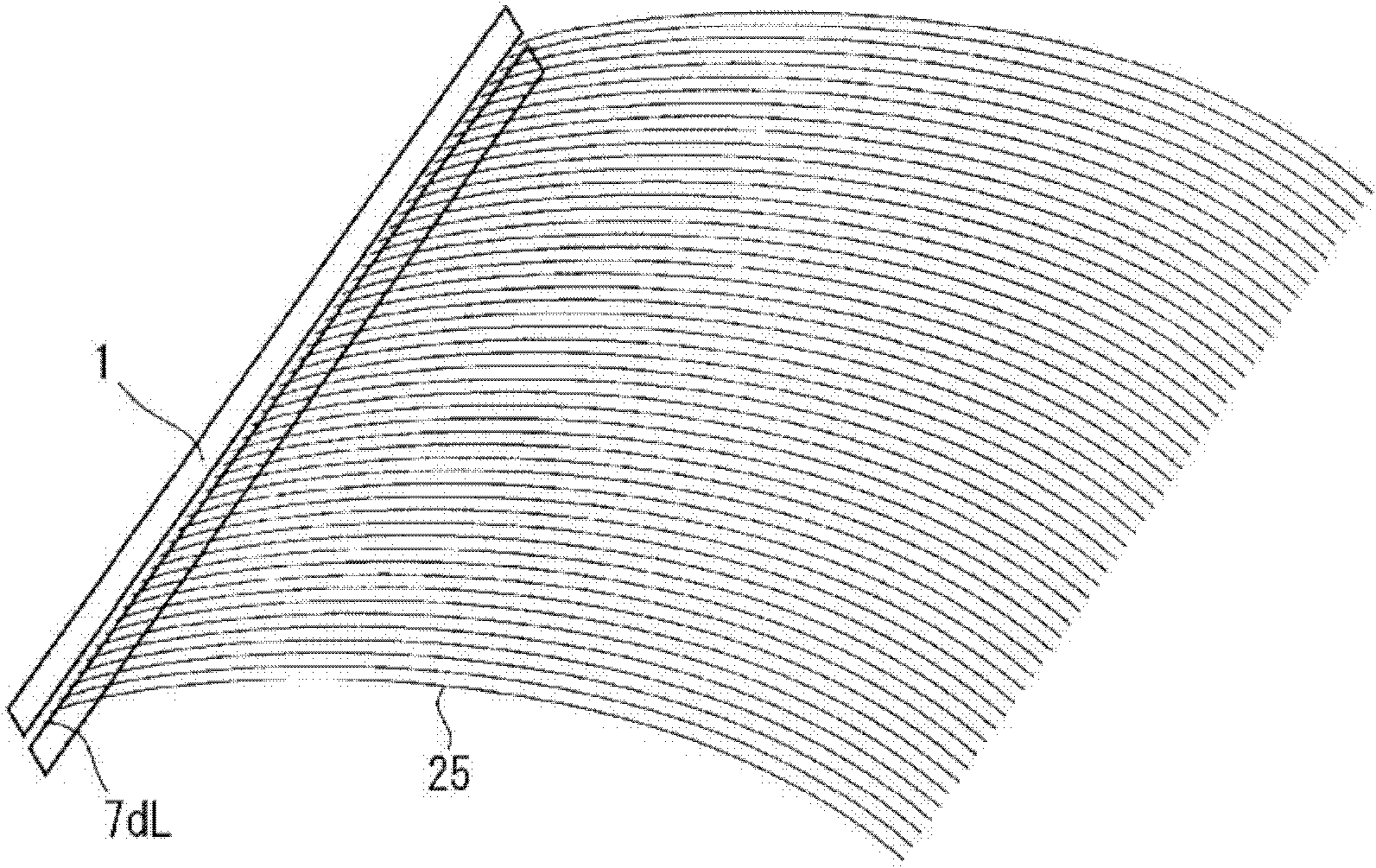

[0041] The inventors of the present application found that water is supplied to the shielding fuel gas cylinder of the flame cleaning mechanism, and the water is sprayed from the shielding fuel gas nozzle, and nozzle clogging can be detected based on the spraying state. That is, if Figure 2B As shown in FIG. 2 , the jetting state of water jetted from nozzles with clogged nozzles is different, so that clogged nozzles can be found at a glance.

[0042] However, the flame cleaning device for steel slabs has: a pressure detection device for detecting the pressure in each gas cylinder in each flame cleaning mechanism; and a pressure detection tube connected between each gas cylinder and each pressure detection device. In this way, the flame cleaning device is designed so that the pressure in each gas cylinder can be detected by the pressure detection device.

[0043] Therefore, when water is supplied to the guard fuel gas cylinder, the water will infiltrate into the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com