Automatic continuous black tea withering machine

A technology of withering machine and black tea, which is applied in the direction of tea treatment before extraction, etc. It can solve the problems of low efficiency, black tea rot, and lowering the quality of black tea, and achieve the effect of improving efficiency, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

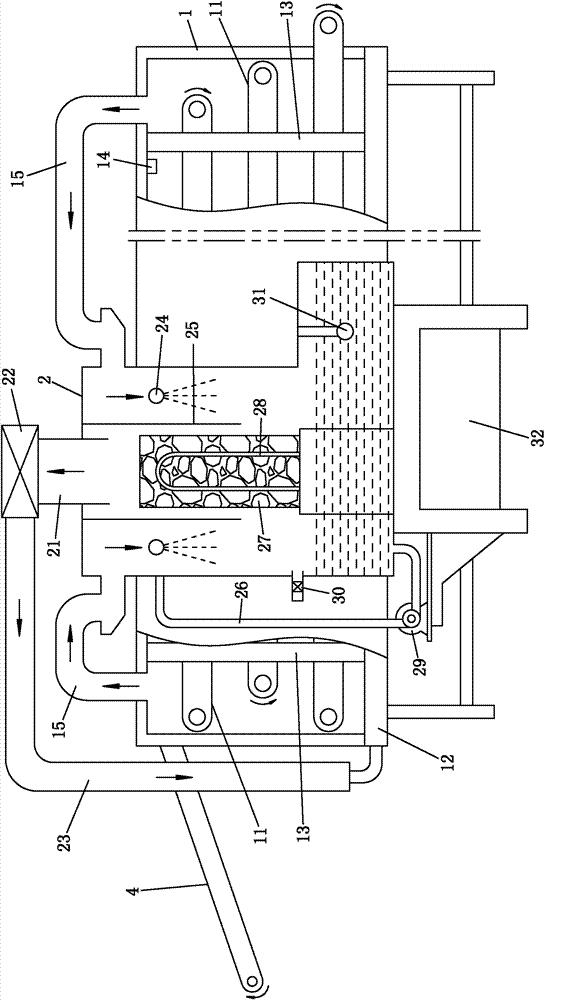

[0012] Example: see figure 1 The present invention comprises a withering box 1 and a cooling and drying tower 2. Several layers of conveyor belts 11 are arranged in the withering box 1. The rotation directions of adjacent conveyor belts 11 are opposite. Black tea enters the withering box 1 after being fed by a feeding belt 4. The inside of the withering box 1 is transported from top to bottom through the conveyor belt 11 layer by layer, and the withering process is completed during the transportation of black tea, and then it is sent out of the withering box 1 for the next process. The air outlet 21 of the cooling and drying tower 2 is provided with a fan 22, and the fan 22 is connected to the main air duct 12 at the bottom of the withering box 1 through the air outlet duct 23. The main air duct 12 is provided with several air ducts 13, which are cooled and dried by the cooling and drying tower. 2. The treated dry cold air is evenly distributed in the withering box 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com