Indoor withering device for tea leaf processing

A technology for indoor withering and tea leaves, applied in the direction of tea treatment before extraction, etc., can solve the problems affecting the color and quality of tea leaves, uneven temperature, uneven drying, etc., to achieve a good user experience, fast drying, and good withering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

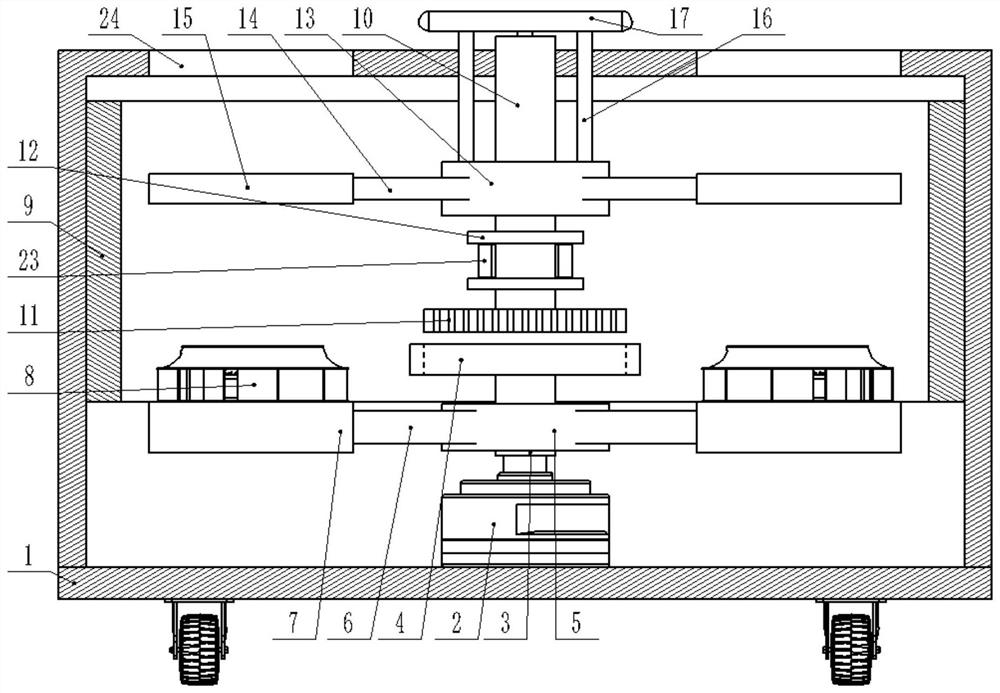

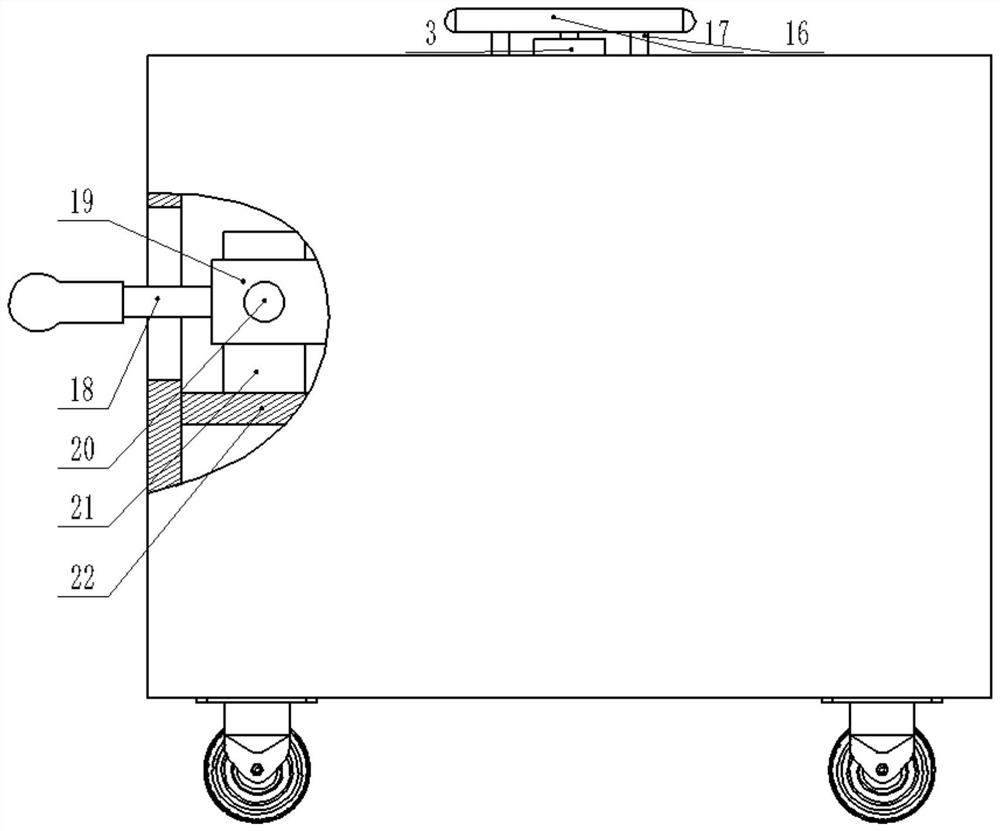

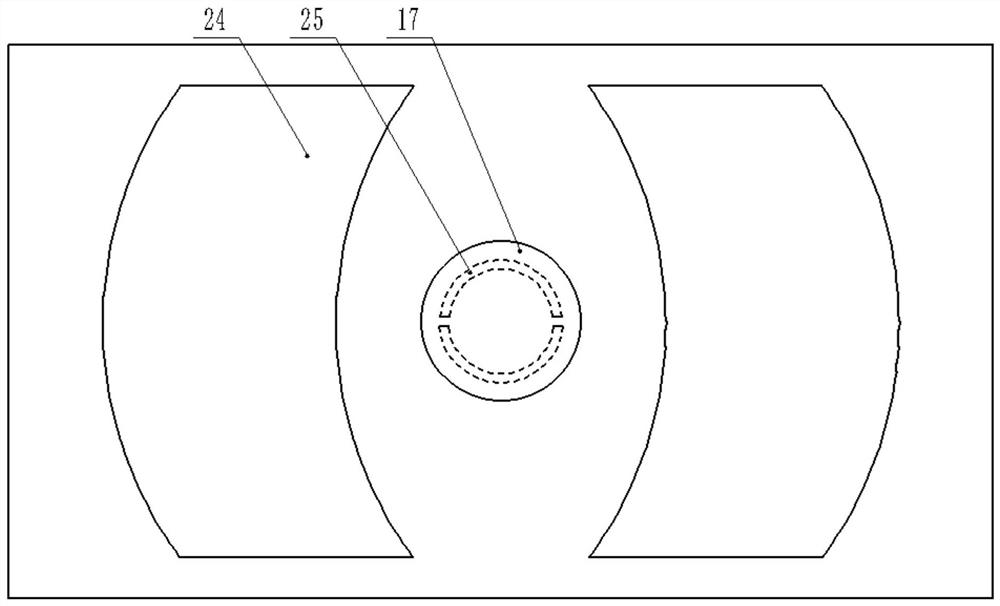

[0021] Example 1: Please refer to Figure 1-4 , an indoor withering device for tea processing, comprising a base 1, a box body is fixedly connected to the top of the base 1, a drive motor 2 is fixedly connected to the middle part above the base 1, a motor shaft 3 is fixedly connected to the output end of the drive motor 2, and a motor shaft 3 is fixedly connected to the top of the motor shaft 3. The gear plate 4 is fixedly connected, the bottom of the motor shaft 3 is fixedly connected with the sleeve 5, the sleeve 5 is symmetrically fixedly connected with the connecting plate 6, and the other end of the connecting plate 6 is fixedly connected with the fan support plate 7, which will be withered before use. The tea leaves are placed above the storage net 15 through the feed port 24, the drive motor 2 is turned on, and the output end of the drive motor 2 drives the motor shaft 3 to rotate, which in turn drives the sleeve 5 to rotate, and then makes the fan support plate fixedly ...

Embodiment 2

[0031] Embodiment 2: The difference between this embodiment and the previous embodiment is that the drive motor 2 is a servo motor.

[0032] The working principle of the present invention is: before use, the tea leaves to be withered are placed on the top of the storage net 15 through the feed port 24, the drive motor 2 is turned on, the output end of the drive motor 2 drives the motor shaft 3 to rotate, and then drives the sleeve 5 to rotate, Then the fan support plate 7 fixedly connected with the connecting plate 6 is rotated, and then the temperature control fan 8 is driven to rotate around the motor shaft 3, and then the temperature control fan 8 is turned on to dry the tea leaves; The limit plate 12 matched with the clamping plate 23 moves downward, and then the gear fixedly connected with the longitudinal axis 10 moves downward to mesh with the gear plate 4, and then drives the screw sleeve 13 to rotate synchronously, and then drives the gear fixedly connected with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com