Conveying device

A technology of conveying device and supply roller, which is applied in the direction of transportation and packaging, object separation, pile separation, etc., and can solve the problems of clutch device and drive side gear engagement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

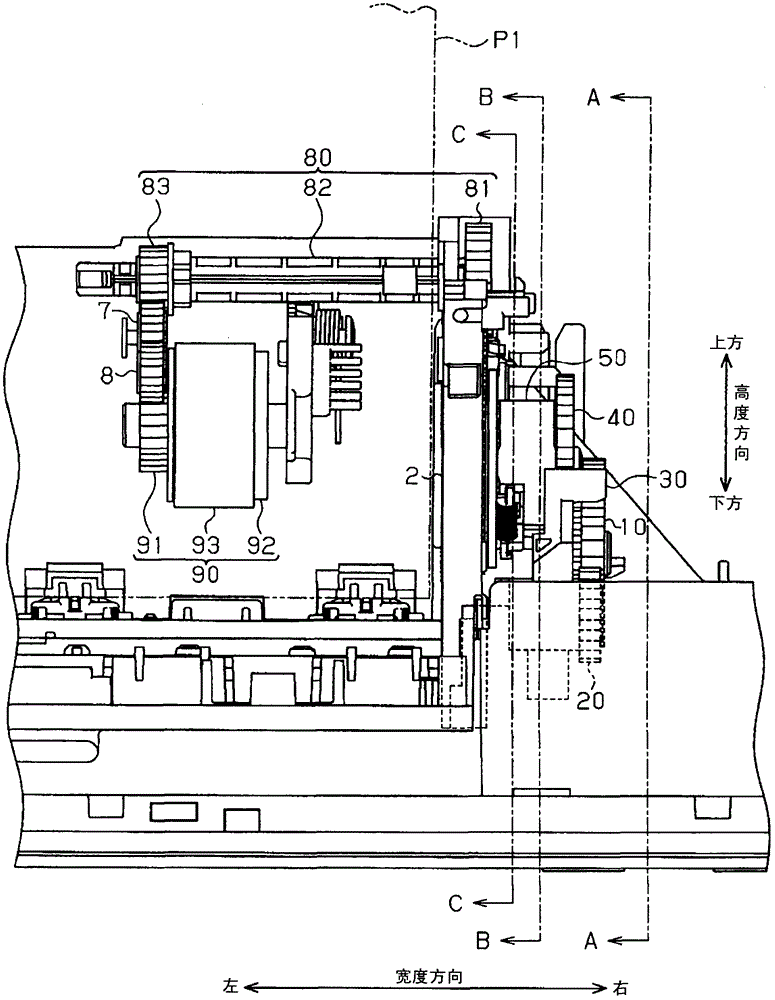

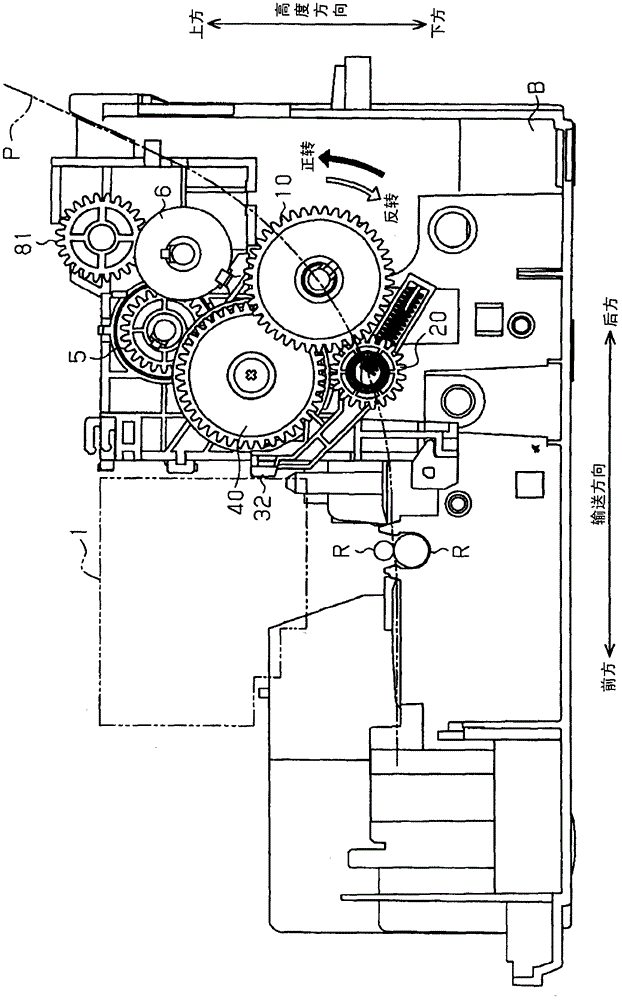

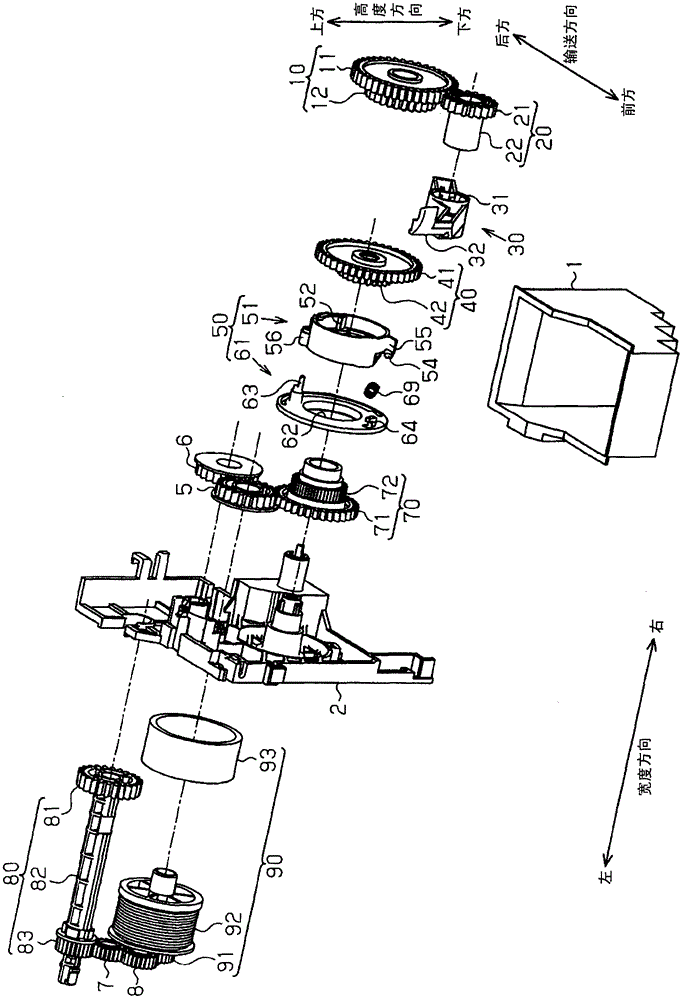

[0032] Below, use Figure 1 to Figure 12 An embodiment in which the transport device of the present invention is mounted on an inkjet printer will be described. In addition, in the following description, directions and orientations indicated by arrows in the drawings are used unless otherwise specified.

[0033] figure 1It is an enlarged front view of main parts of the conveying device mounted on the printer viewed from the front of the printer. For convenience of description, the housing of the printer and the like that are not directly related to the conveying device are omitted. in addition, figure 2 yes figure 1 A-A cutaway view. The positional relationship seen from the side of the members constituting the conveying device is clearly shown. In addition, in image 3 The shown exploded perspective view clearly shows the shape of each structural component.

[0034] Such as Figure 1 ~ Figure 3 As shown, the main part of the conveying device is rotatably supported o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com