Additive manufacturing method for aluminum-based boron carbide structures for neutron protection

An aluminum-based boron carbide and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as inability to form complex structures, and achieve the effects of increasing boron carbide content, reducing volume, and accurate placement and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

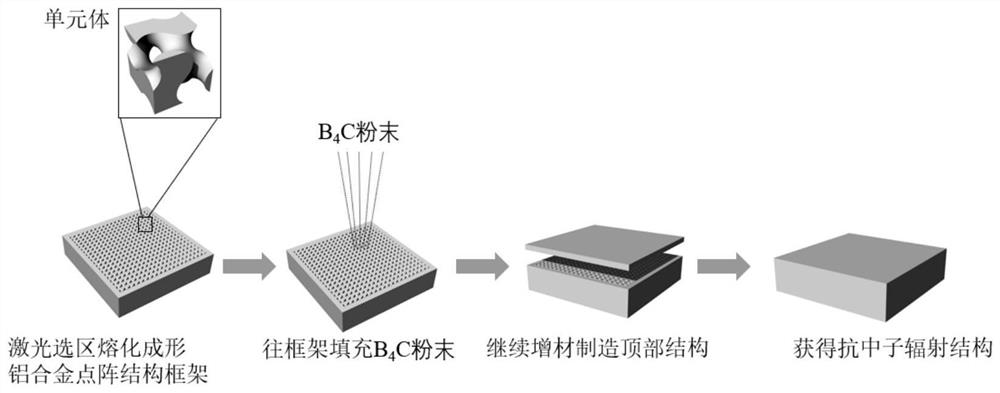

[0035] Such as process figure 1 As shown, the present invention provides an additive manufacturing method for an aluminum-based boron carbide structure for neutron protection. The steps include forming a complex aluminum alloy lattice structure, filling boron carbide powder, and sealing the aluminum alloy lattice structure.

[0036] The forming of the complex aluminum alloy lattice structure refers to the formation and manufacture of the aluminum alloy lattice structure frame by laser selective melting technology; the aluminum alloy lattice structure frame is redesigned into a lattice structure through topology optimization; the characteristics of the lattice structure are: The interior is a porous structure with a certain porosity, while the exterior contour is solid but has a boron carbide powder filling port (surface);

[0037] The boron carbide powder filling refers to pouring fine boron carbide powder into the aluminum alloy lattice structure, so that the powder fills the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com