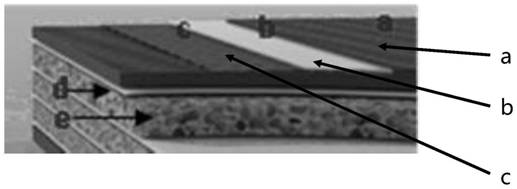

Composite board for ocean platform living quarter enclosure wall and preparation method of composite board

A technology for offshore platforms and living quarters, which is applied in the field of composite panels for surrounding walls of living quarters on offshore platforms and its preparation. problems, to achieve the effect of increasing payload and operating range, improving strength, and reducing the weight of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The short fiber reinforced toughened interfacial layer film material is prepared by papermaking process. The specific process is as follows:

[0031] (1) Aramid fibers are chopped into short fibers with a length of 3 mm, and dispersed in an ethanol solution by ultrasonic vibration,

[0032] (2) After the dispersion is even, the dispersion liquid is diluted to contain 10g chopped aramid fiber in every 1Kg ethanol solution,

[0033] (3) beating, the solution is formed into a certain suspension by the method of mortar pounding;

[0034] (4) Papermaking, use a paper machine to scoop out the pulp, so that the short fiber pulp is evenly interwoven into a sheet film on the paper scoop, and finally prepare a short fiber toughening interface with an area density of 10g / cm2 through the papermaking process Layer film, set aside.

[0035] (5) Dry, then peel off the film and set aside.

[0036] 2. Preparation of carbon fiber / phenolic resin composite layer, the specific process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com