Twin wire twisting or cabling spindle

一种倍捻锭子、捻线的技术,应用在纺织品和造纸、接头装置、连续卷绕的纺纱机等方向,能够解决给纱筒子没有受保护等问题,达到通风损失降低、驱动能量降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

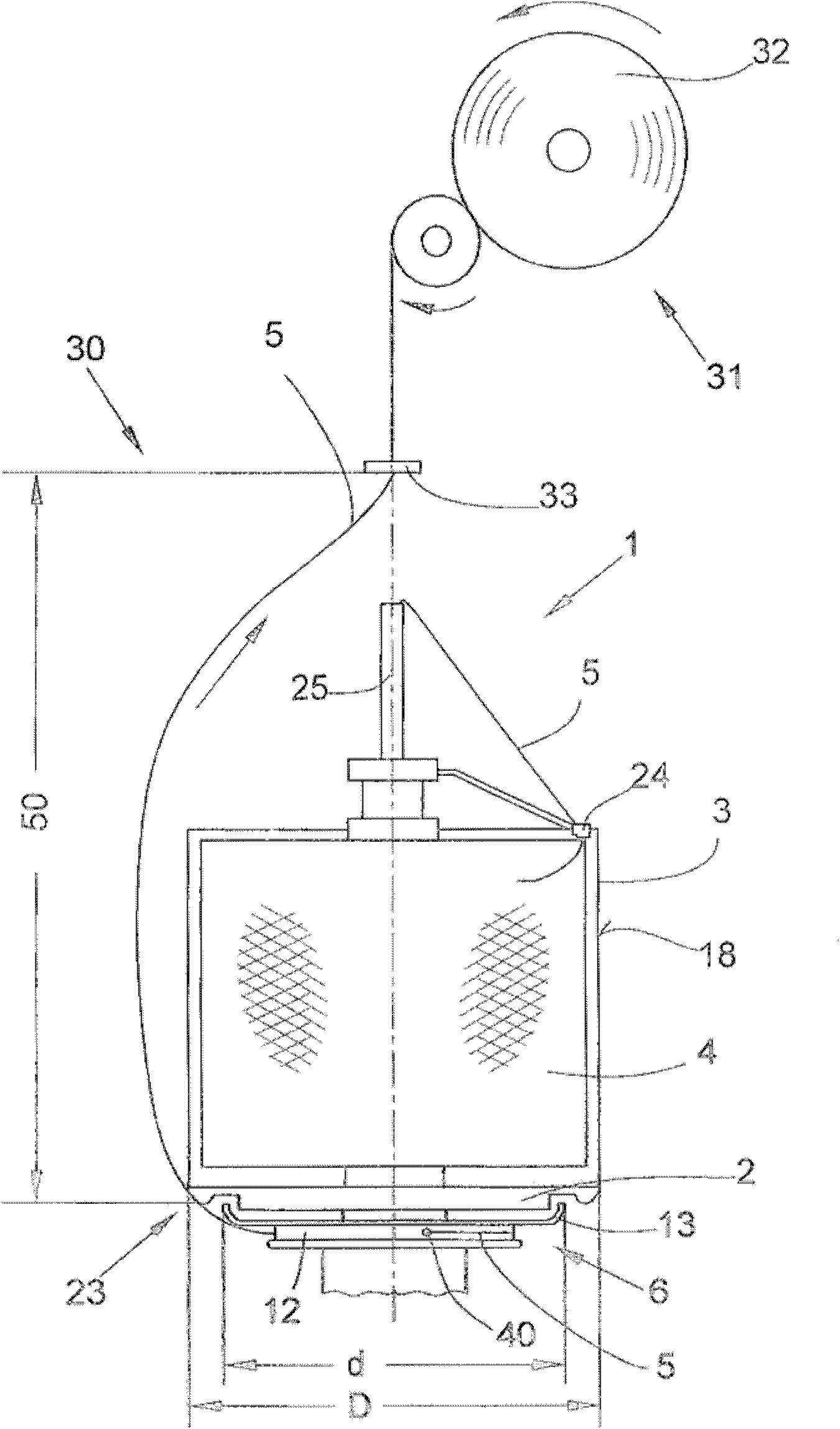

[0031] figure 1 The working position 30 of a two-for-one twister or multi-strand twister (not shown in detail) is schematically shown.

[0032]Such a working station 30 has, inter alia, a two-for-one-twisting spindle or twisting spindle 1 with a yarn supply bobbin 4 supported in a stationary protective housing 3 and for winding the twisted yarn 5 onto a winding bobbin 32 winding device 31.

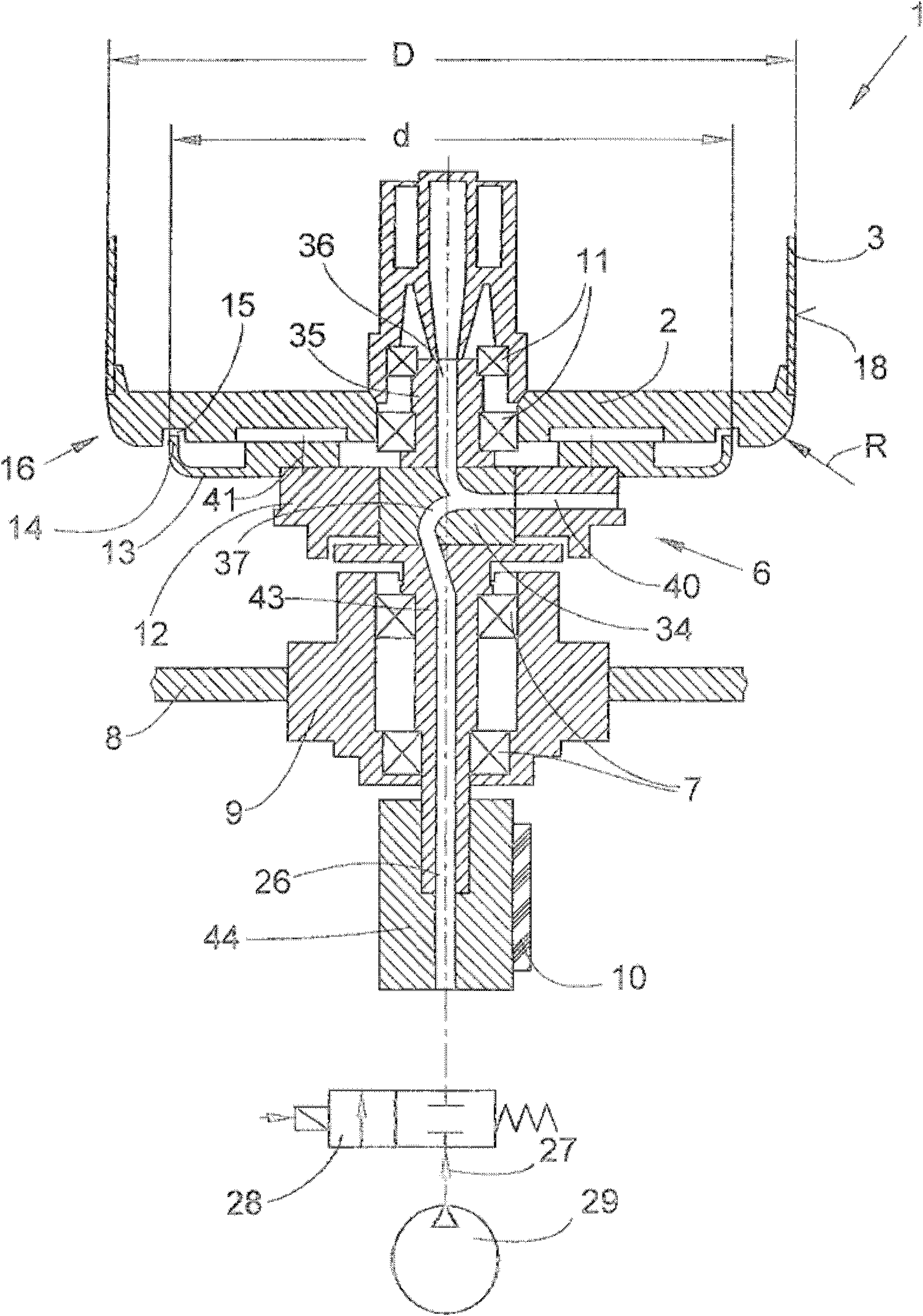

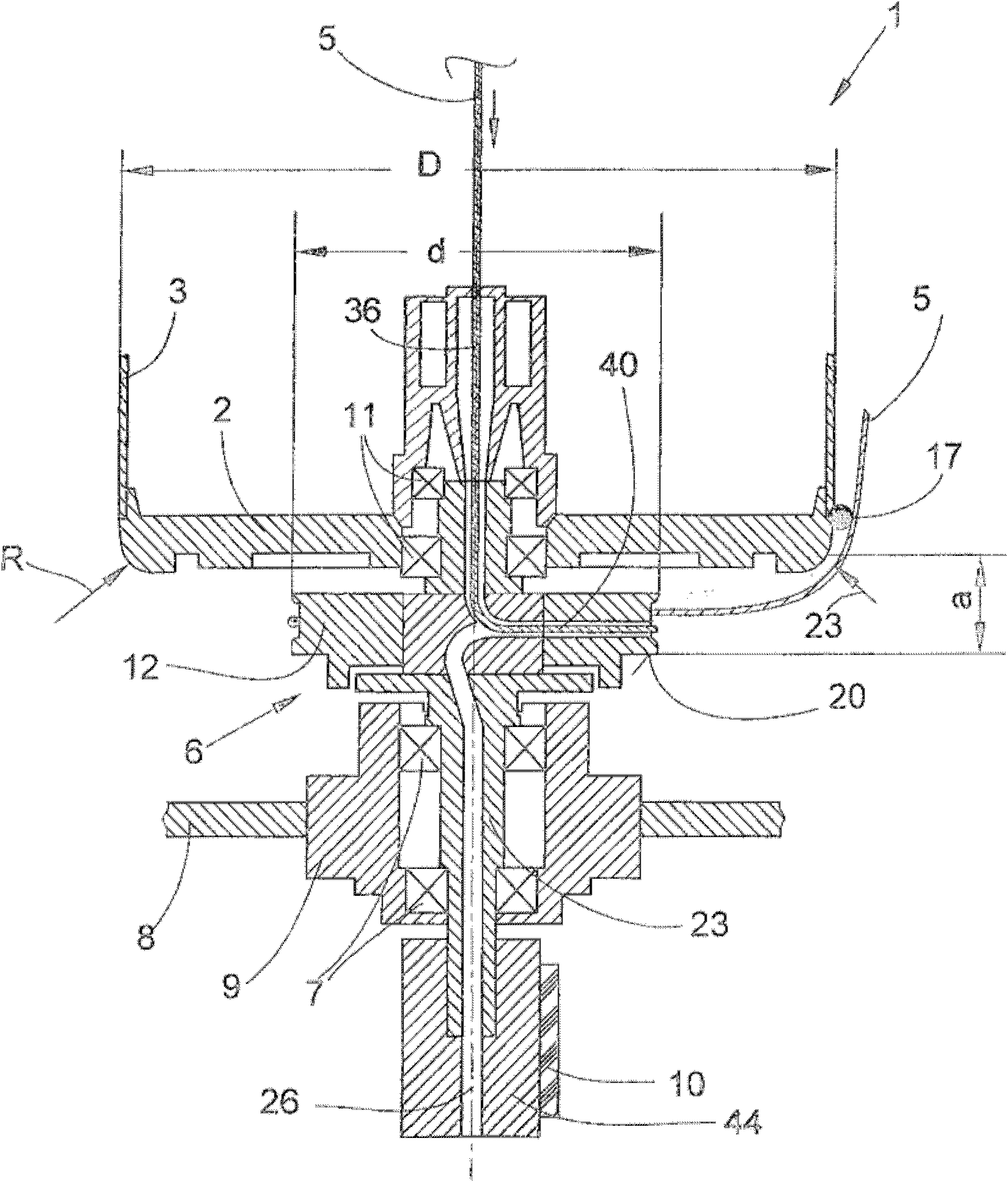

[0033] The stationary protective housing 3 with a relatively large diameter D has a housing base 2 . A rotatably mounted spindle 6 of the two-for-one twisting spindle or the twisting spindle 1 is arranged below the hood base 2 .

[0034] exist figure 1 In the illustrated embodiment, the spindle 6 is equipped with a storage disk 12 and a yarn discharge disk 13 in order to rotate and guide the yarn 5 during twisting or twisting, as shown in the figure, which constitutes a rotatable support at this time. The largest diameter of the unloading disc 13 of the spindle 6 is significantly small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com