Embroidery needle for woolen embroidery and woolen embroidery method

An embroidery needle and velvet embroidery technology, which is applied to the production of fleece products, etc., can solve the problems of thickness limitation, the sharp edge of the needle point is easy to damage the embroidery cloth, and the thread cannot pass through, etc., to achieve perfect effect and fine surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

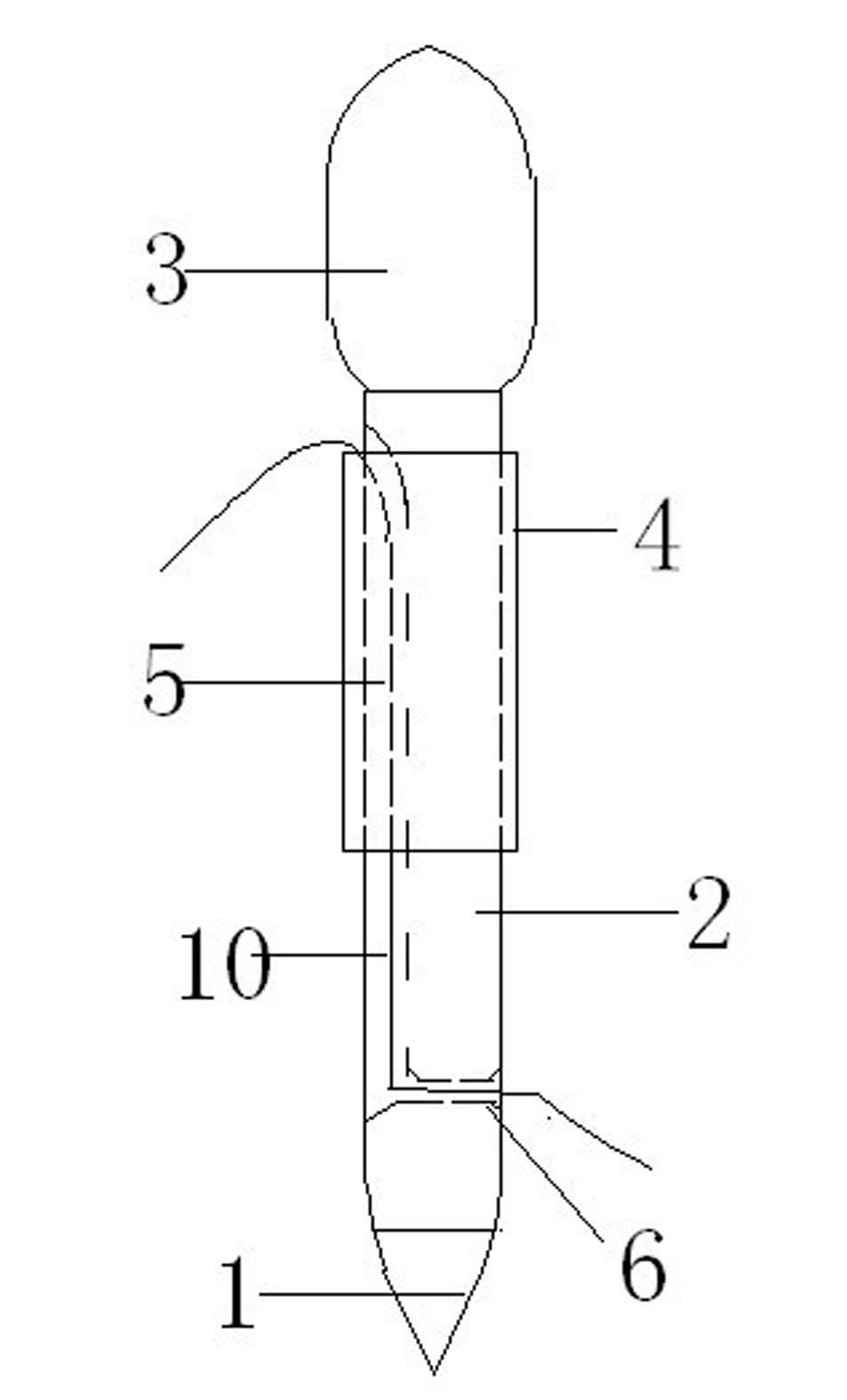

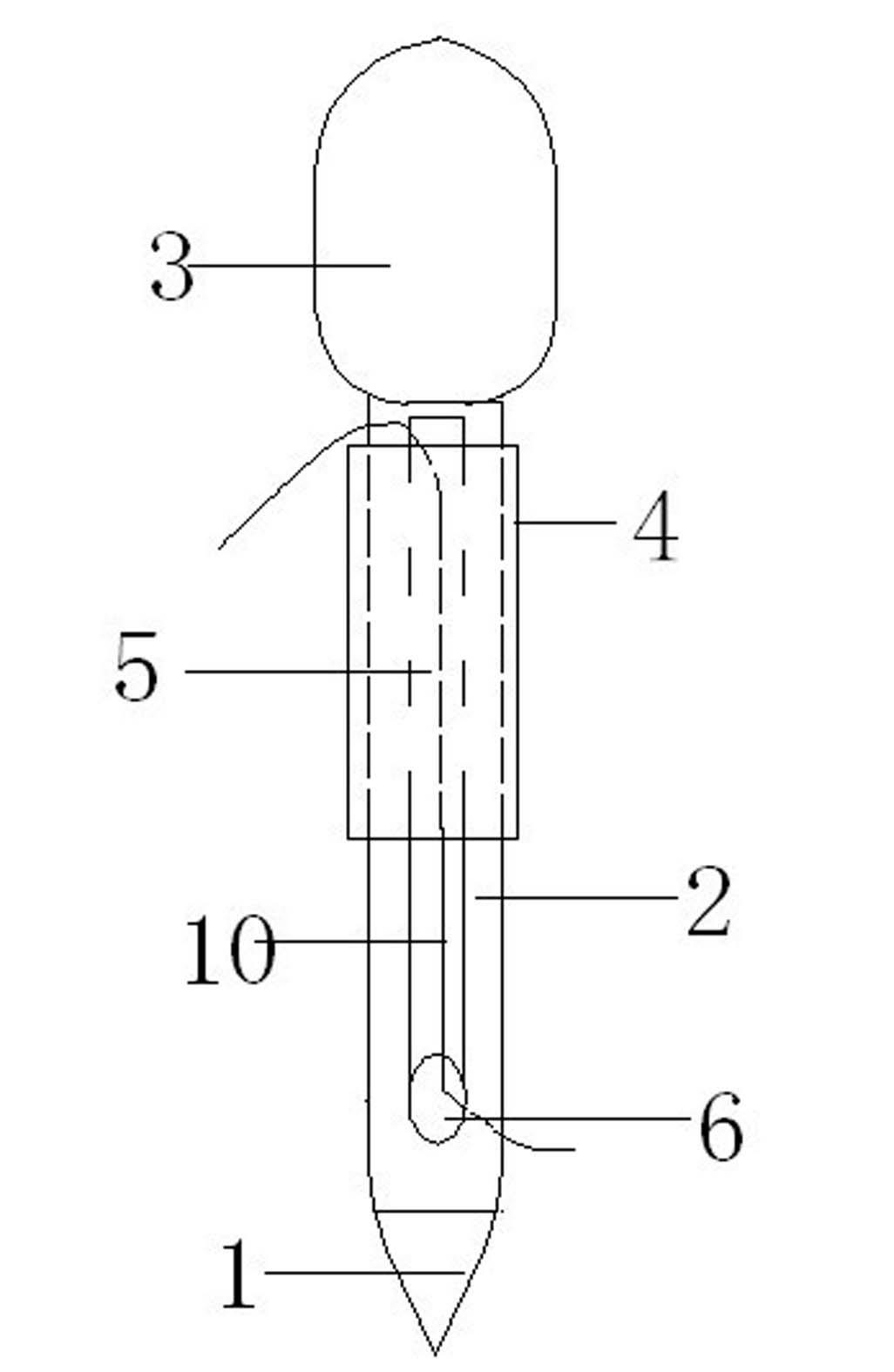

[0032] An embroidery needle for velvet embroidery, comprising a needle point 1, a needle body 2, a handle 3 and a positioning sleeve 4.

[0033] The lower end of the needle body 2 is fixed with a conical needle point 1, the needle body 2 and the needle point 1 are integrated, the upper end of the needle body 2 is fixed with a handle 3, and the outer surface of the needle body 2 is provided with a slot 5 in the axial direction.

[0034] A pinhole 6 is provided on the needle body 2, and the pinhole 6 communicates with the slot 5.

[0035] The positioning sleeve 4 is set on the needle body 2, and the positioning sleeve 4 is closely matched with the needle body 2.

[0036] The upper opening of wire slot 5 is arc-shaped, and the place where wire slot 5 communicates with pinhole 6 is arc-shaped, and the outlet of pinhole 6 is arc-shaped, and multiple arcs are set to facilitate threading. The conical needle point 1 has a smooth surface and does not damage the embroidered cloth.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com