One-piece transmission shaft assembly

A transmission shaft and assembly technology, which is applied in the field of connected transmission shaft assembly for automobiles, can solve the problems of increasing the unbalance of the overall transmission shaft and affecting the practical performance of the car, and achieve the effect of improving the performance and reducing the unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

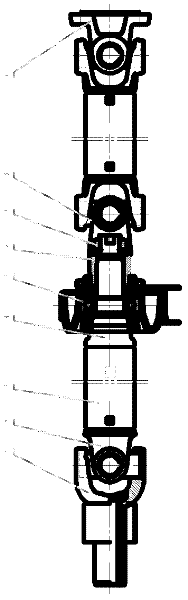

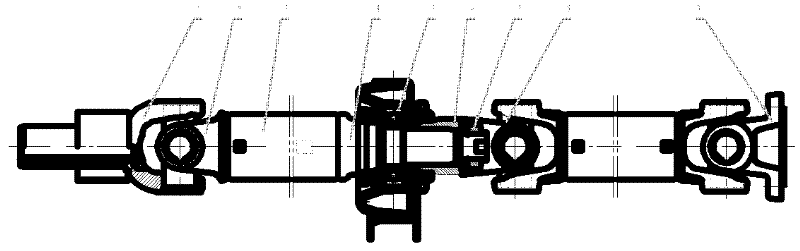

[0009] As shown in Figure 1, the outer circle of the spline shaft 4 of the present invention is welded to the shaft tube 3, the other end of the shaft tube 3 is welded to the shaft tube fork 2, and the shaft tube fork 2 and the sliding fork 1 are connected by a cross shaft 8. ; The other end of the spline shaft 4 and the suspension assembly 5 through the outer circle and the bearing inner hole interference fit, and the intermediate sliding fork 6 through the spline connection, and the spline shaft 4 and the intermediate sliding fork 6 are locked with a nut 7, The intermediate sliding fork 6 is connected to the shaft tube yoke 2 through the cross shaft 8, and the shaft tube yoke 2 and the flange fork 9 are connected through the cross shaft 8. Through the above settings, the front and rear drive shafts are connected to form a conjoined drive shaft assembly. After the overall dynamic balance, the unbalance of the drive shaft after loading is minimized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com