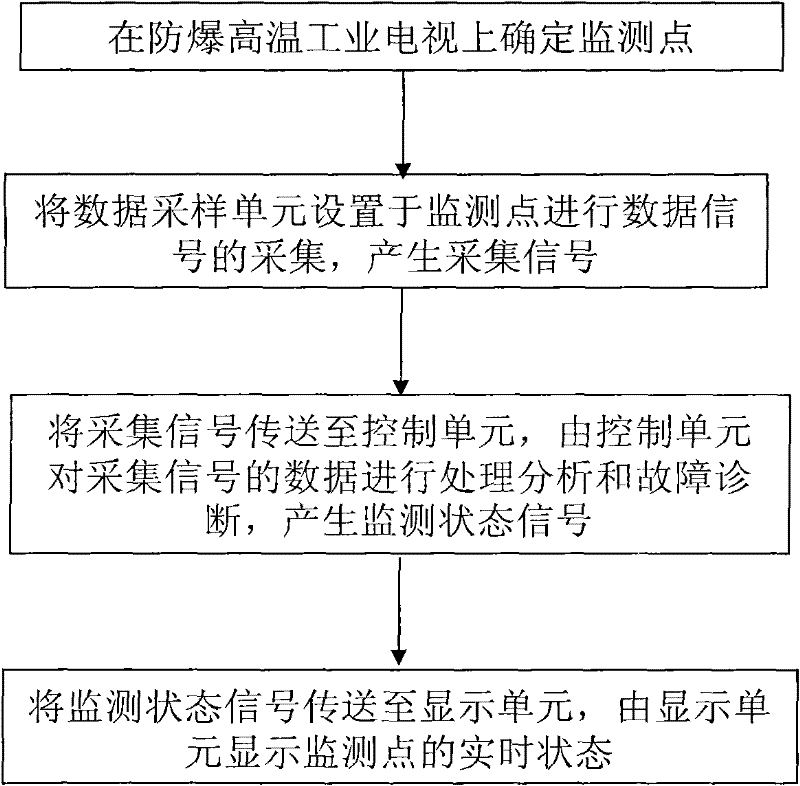

Monitoring method for anti-explosive high-temperature industrial television

A high-temperature industrial and television technology, applied in television, electrical components, image communication, etc., can solve problems such as inability to accurately monitor and diagnose explosion-proof high-temperature industrial televisions in real time, shorten maintenance time, avoid misjudgment, and improve maintenance efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

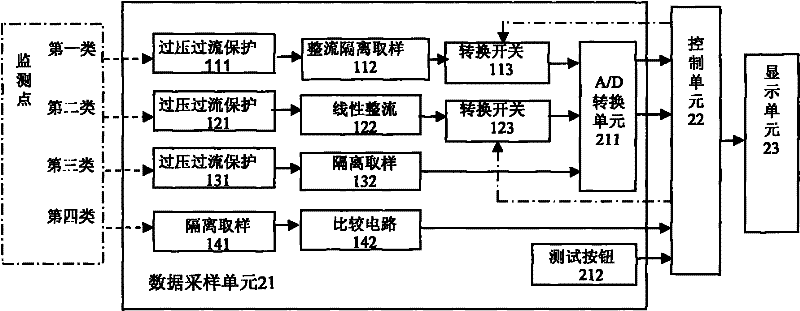

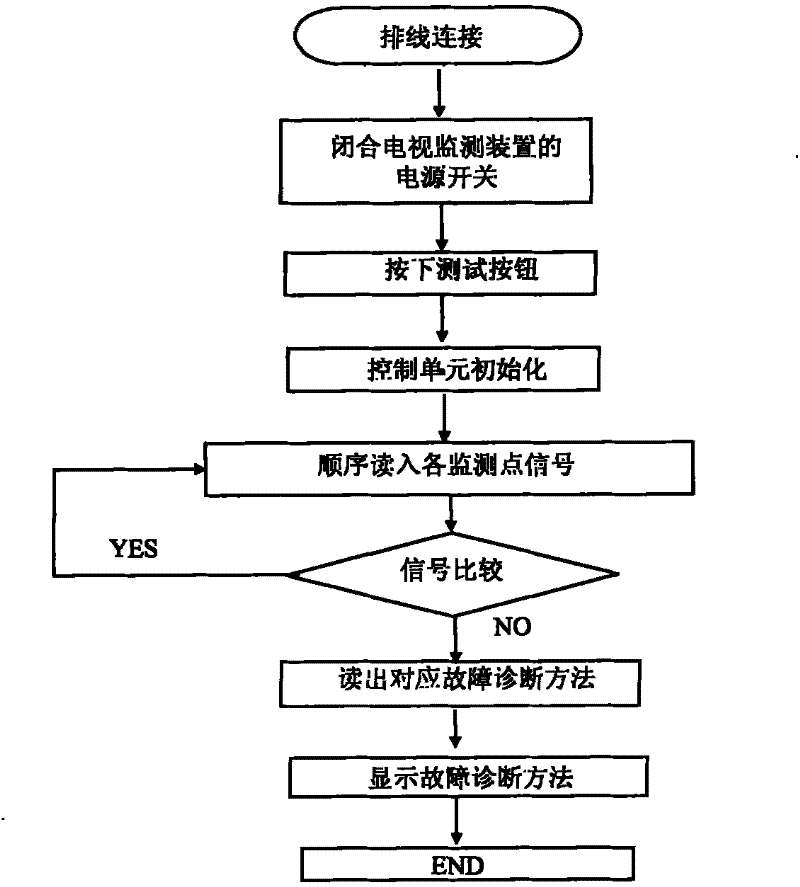

[0039] First of all, make a general introduction to the explosion-proof high-temperature industrial TV. The explosion-proof high-temperature industrial TV can be divided into a camera control part and a cooling protection part. DC 16V and 12V), power control board, conversion relay, air pressure sensing controller, relay K1 (responsible for starting the camera), relay K2 (responsible for starting the lighting), relay K3 (responsible for starting the air pressure sensing controller), etc.; cooling The protection part includes 1# water flow switch relay, 2# water flow switch relay, gas control switch, cooling water supply circuit, protective gas supply circuit, etc., and then set the corresponding monitoring points one by one according to the fault diagnosis method.

[0040] There are 17 monitoring points in total, which are: switching relay start input 331, relay K3 control input 371, air pressure sensor controller start input 342, air pressure sensor controller water pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com